Manufacturing technology for water drop head seat back plate

A manufacturing process and backboard technology, which is applied in the field of water drop head seat backboard manufacturing technology, can solve the problems of easy deformation cost, low impact resistance, poor strength, etc., and achieve low cost, high impact resistance, and material utilization high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

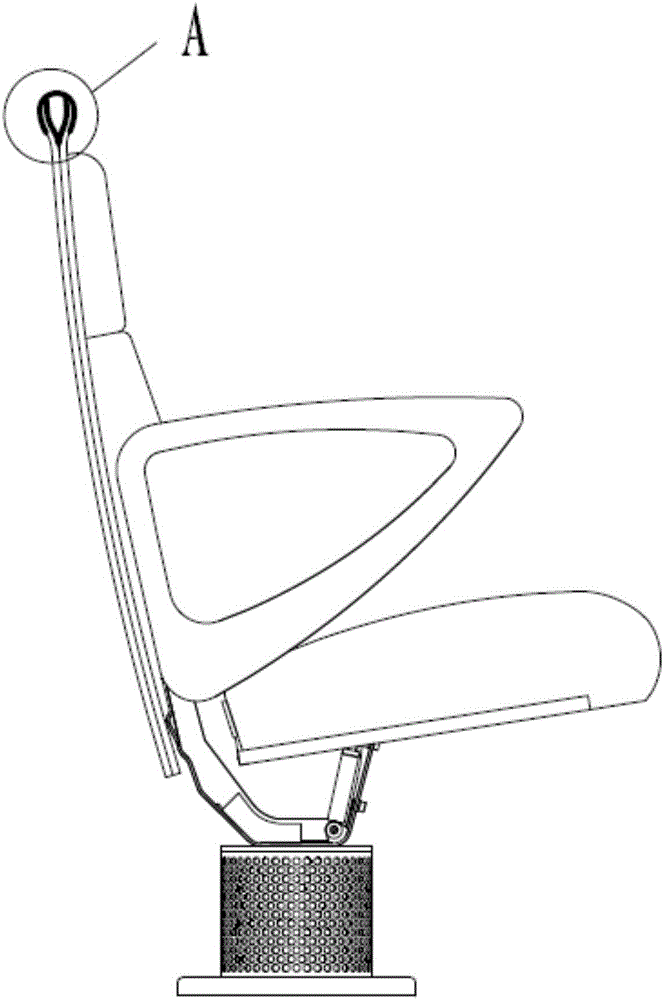

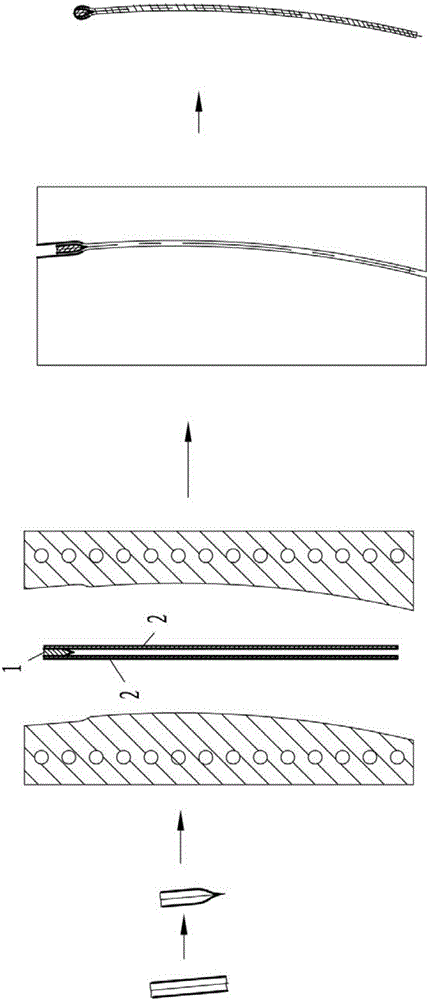

[0032] like Figure 2-Figure 4 The manufacturing process of a water drop head seat backboard shown includes the following steps:

[0033] a. Make an insert blank 1 in the shape of a water drop head, wherein the bottom of the insert blank 1 is processed into a tooth shape;

[0034] b. Put the plate, insert blank 1 and plate 2 on the lower mold in sequence, and the upper mold is installed on a 300-ton press and is molded with the lower mold. Plate 2, insert blank 1 and plate 2 Carry out hot pressing and keep it for 15 minutes so that the backboard of the seat is preliminarily formed. Specifically, the front and rear sides and the bottom of the insert blank 1 are all wrappe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com