Traction connecting rod mechanism for railway vehicles and frame protection method

A rail vehicle and traction link technology, applied in the direction of railway vehicles, bogies, motor vehicles, etc., can solve the problems of inability to protect the frame, inability to buffer the track and the bogie, inability to protect the bogie, etc., so that the vehicle can turn easily and increase The effect of rotational force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

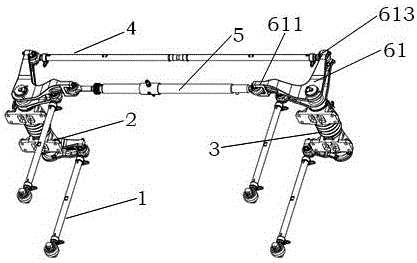

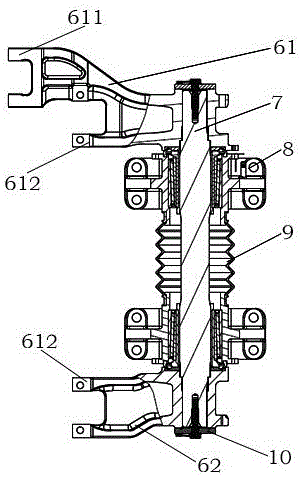

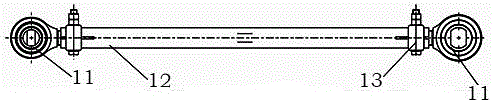

[0030] Such as figure 1 and figure 2 As shown, the anti-roll bar assembly includes a left anti-roll bar assembly 2 and a right anti-roll bar assembly 3 , and the structures of the left anti-roll bar assembly 2 and the right anti-roll bar assembly 3 are distributed symmetrically. The transmission shaft 7 is arranged in the middle of the anti-roll bar assembly, and the transmission arm includes an upper transmission arm 61 and a lower transmission arm 62. The upper transmission arm 61 is located at the upper end of the transmission shaft 7, and the lower transmission arm 62 is located at the lower end of the transmission shaft. The transmission arm is fixedly matched with the transmission shaft 7, and is positioned with the shaft shoulder 10. The transverse link assembly 4 and the hydraulic spring assembly 5 are installed between the upper transmission arms 61 of the two sets of anti-roll bar assemblies, and the drawbar assembly 1 is installed in the drawbar assembly support 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com