Ground zero-gravity separation test equipment for large spacecraft

A separation test and spacecraft technology, applied in ground installations, aircraft parts, transportation and packaging, etc., can solve the problems of inability to obtain accurate separation speed, not meeting test requirements, etc., to achieve safe and reliable separation process, wide quality range, separation Adjustable stroke effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The large-scale spacecraft ground zero-gravity separation test equipment of the present invention will be further described below in conjunction with the accompanying drawings. This description is only exemplary and is not intended to limit the protection scope of the present invention.

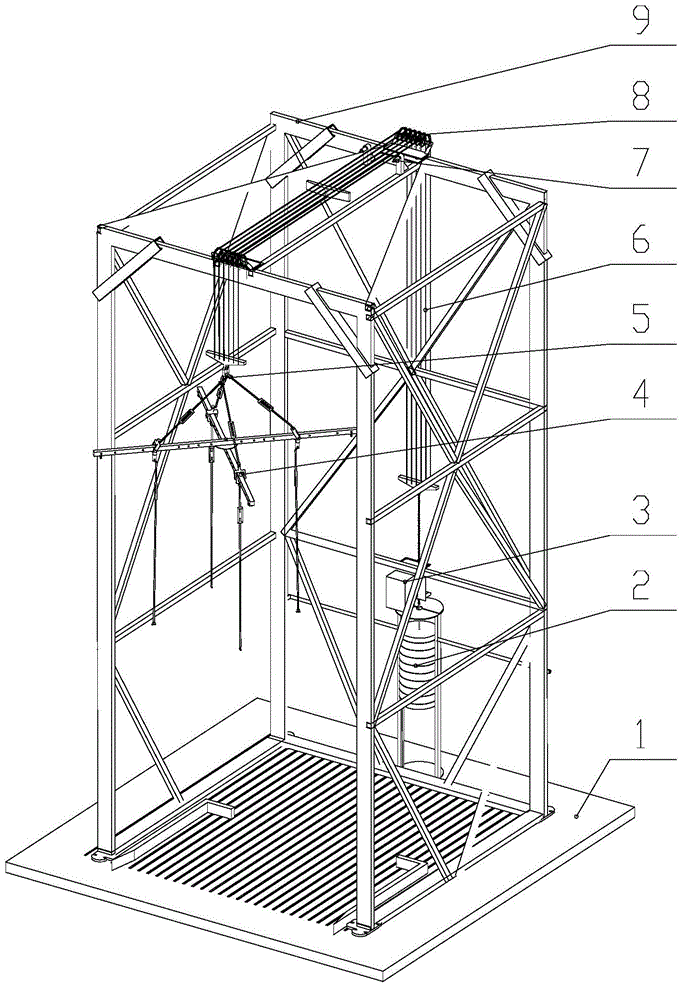

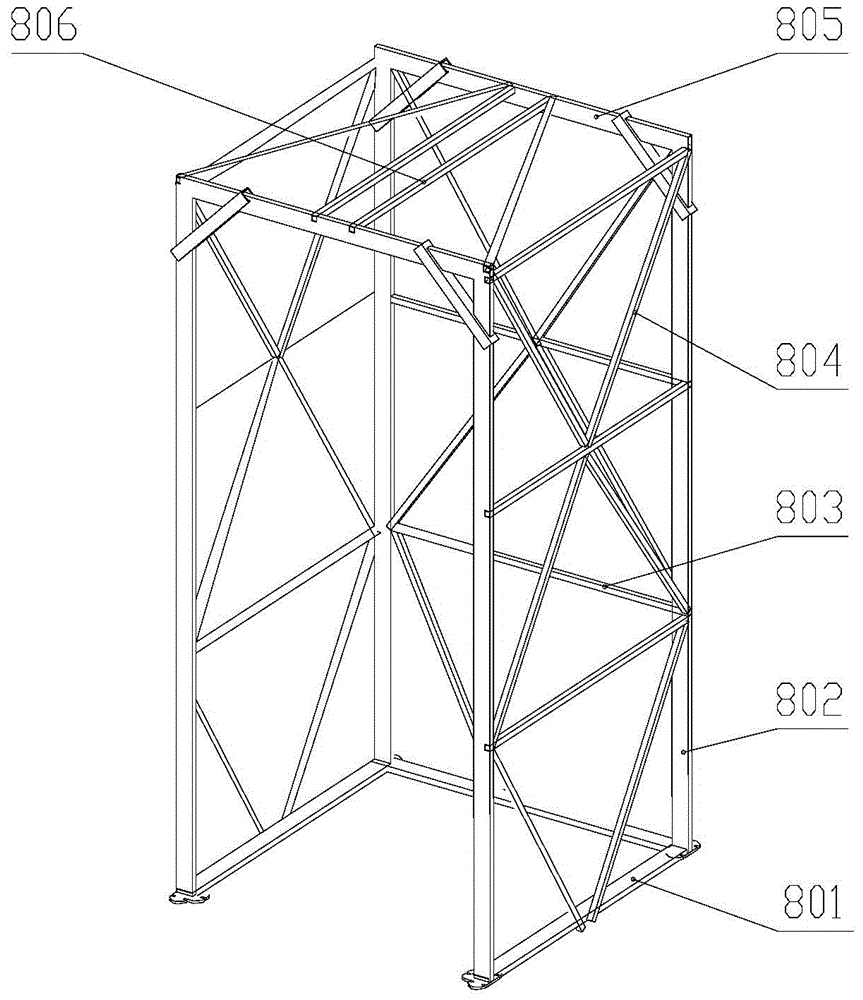

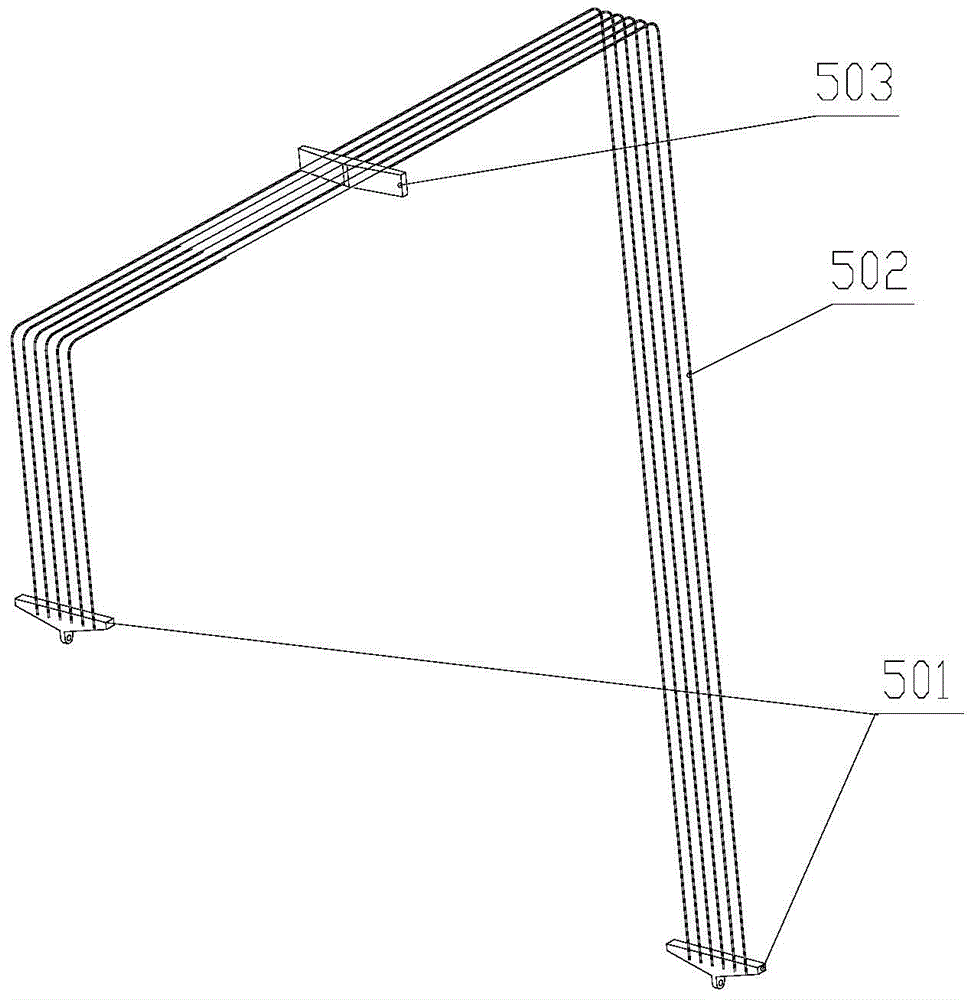

[0041] figure 1It is a structural schematic diagram of the large-scale spacecraft ground zero-gravity separation test equipment of the present invention. Ground zero-gravity separation test equipment for large spacecraft, including test bracket 9, pulley assembly (pulley mechanism 8), buffer mechanism 7, locking mechanism 3, connecting rope 6, counterweight and lifting mechanism 2, tension recorder 5 and test spreader 4. The test bracket 9 is a cubic frame structure, and the three sides of the frame structure are respectively provided with rice-shaped reinforcing support rods, and the angles between the four columns constituting the frame structure and the beams connecting the columns ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com