Fire-fighting main machine housing handling mechanism with automatic locking function

A fire-fighting host, automatic locking technology, applied in conveyors, conveyor objects, transportation and packaging, etc., can solve problems such as low efficiency and poor effect, and achieve good effect and improve work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

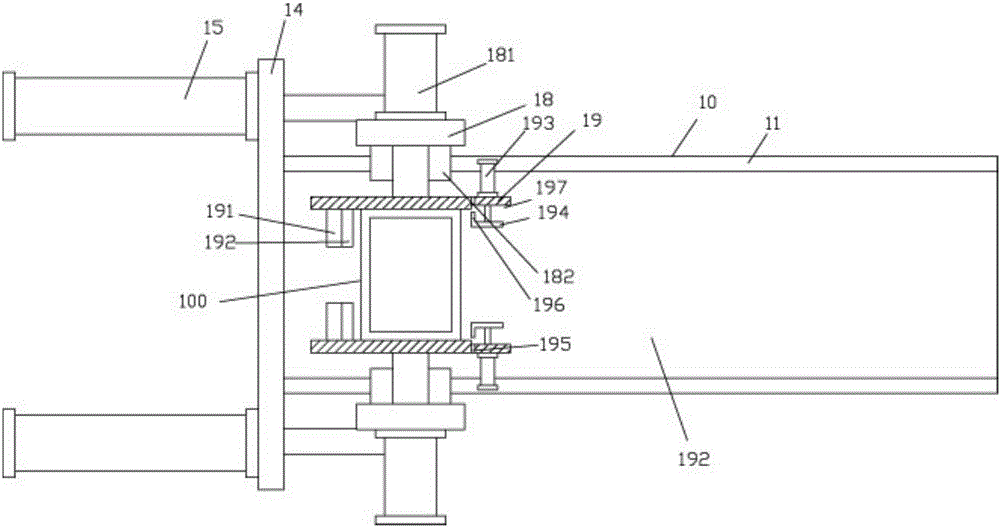

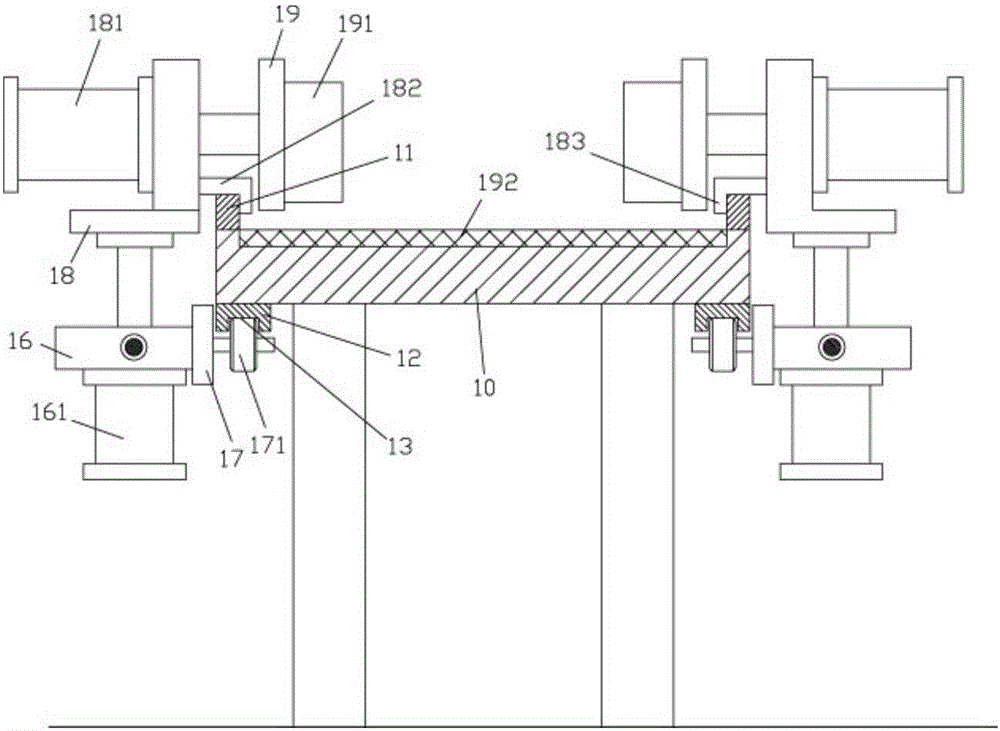

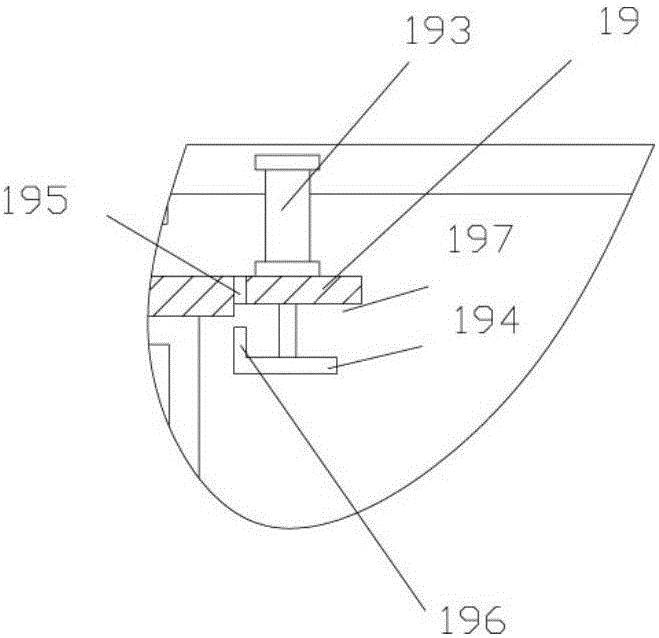

[0020] Examples, see e.g. Figure 1 to Figure 3 Shown, a kind of fire-fighting host housing transporting mechanism with automatic locking function comprises transporting frame 10, the top front and rear sides of the top plate of described transporting frame 10 are fixed with guide bar 11, the top plate of transporting frame 10 Bottom guide rails 12 are fixed on the front and rear sides of the bottom, and the bottom surface of the bottom guide rails 12 is formed with a bottom chute 13. The left end face of the top plate of the transport frame 10 is fixed with a left connecting plate 14, and on the left side wall of the front and rear ends of the left connecting plate 14 Both are fixed with a push cylinder 15, the push rod of the push cylinder 15 passes through the left connecting plate 14 and is fixed with a support plate 16, the support plate 16 is fixed with a connecting block 17, and the connecting block 17 is hinged with a roller 171, and the roller 171 inserts Covered in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com