Reciprocating type vertical conveying system

A conveying system and vertical conveyor technology, applied in conveying objects, transportation and packaging, etc., can solve the problems of complicated operation process, delayed conveying time, low conveying efficiency, etc. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

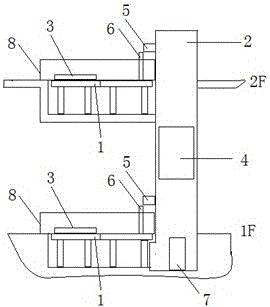

[0019] The reciprocating vertical conveying system proposed by the present invention mainly includes a common conveyor 1 and a vertical conveyor 2. The common conveyor 1 includes a first-stage shelf conveyor and a second-stage shelf conveyor, and the common conveyor 1 There is a conveying plate 3 on the top, the goods are placed on the conveying plate 3 of the first shelf conveyor, and the goods are automatically sent to the second stage shelf conveyor, and then the second stage shelf conveyor automatically transports the goods to the vertical In the lifting trolley 4, a space is formed on the shelf conveyor in the second stage at this time, and the next goods are placed on the conveying plate 3 of the shelf conveyor in the first stage, and the reciprocating operation is performed, and the vertical lifting trolley 4 sends the goods to the second floor at the same time , and then the goods are discharged through the ordinary conveyor 1 on the second floor to complete the entire ...

Embodiment 2

[0022] The reciprocating vertical conveyor system proposed by the present invention mainly includes a common conveyor 1 and a vertical conveyor 2. The common conveyor 1 includes an electric lifting platform, a chain conveyor and a double-layer chain conveyor line, and the common conveyor 1 is equipped with There is a conveying board 3 on which the goods are placed. After the electric lifting platform raises the conveying board 3 and the goods to the highest position, the horizontal conveyor sends the conveying board 3 and the goods to the upper layer of the double-layer chain conveyor line at the entrance and exit. After the plate 3 and the goods are separated from the electric lifting platform, the electric lifting platform lowers the horizontal conveying line to a low position, and places the next goods on the empty conveying plate, reciprocating operation, and at the same time, the vertical lifting trolley 4 sends the goods to the second floor, Then the goods are discharged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com