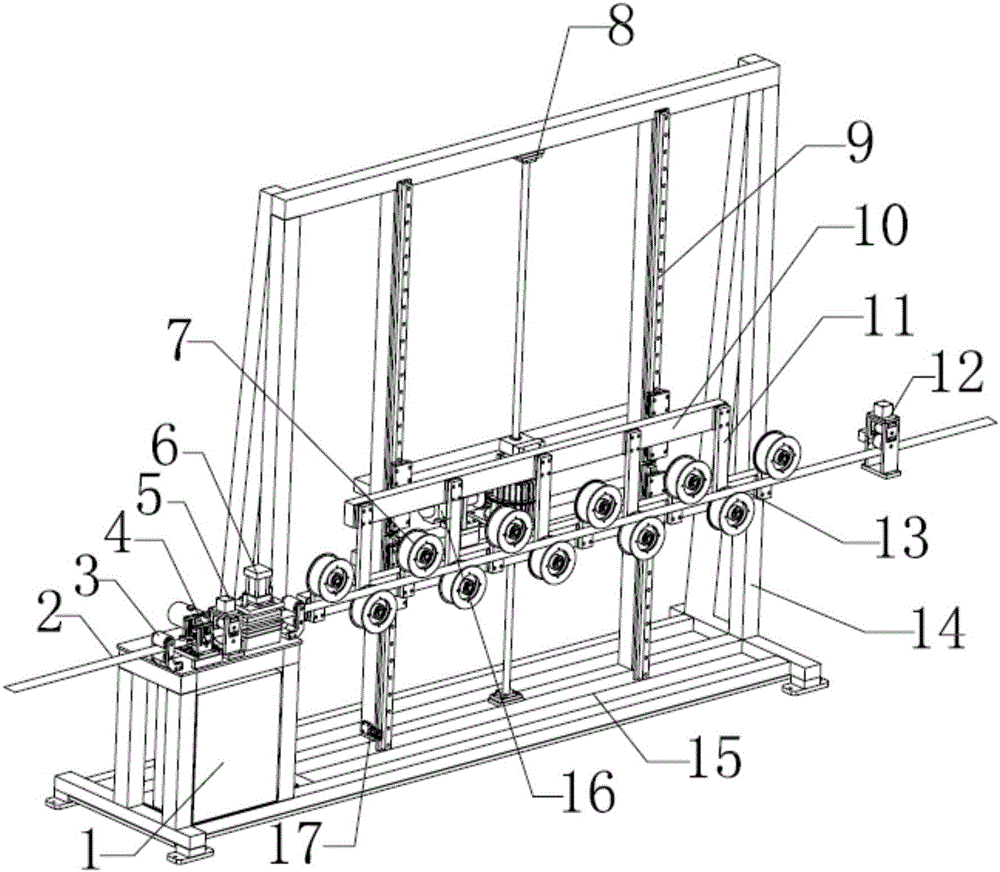

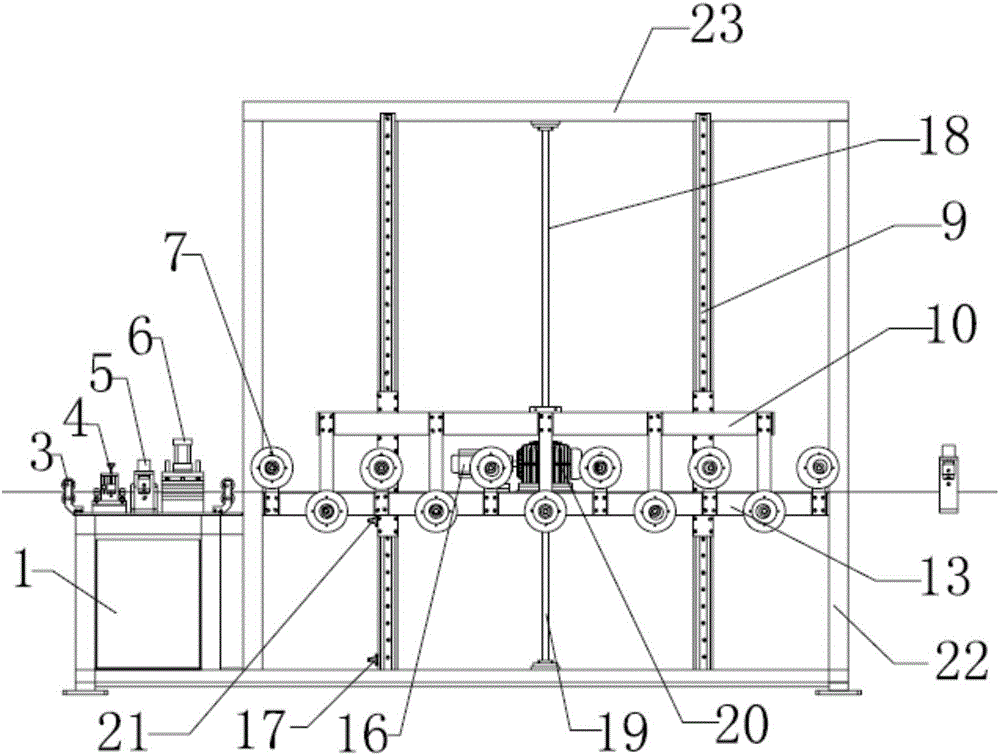

Coextrusion steel belt storage machine

A storage machine and steel strip technology, which is applied in the field of storage machines, can solve the problems of continuous production in the production line, impact on product quality, and scratches on the surface of the steel strip, so as to avoid product scrapping, reduce equipment production costs, and improve production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

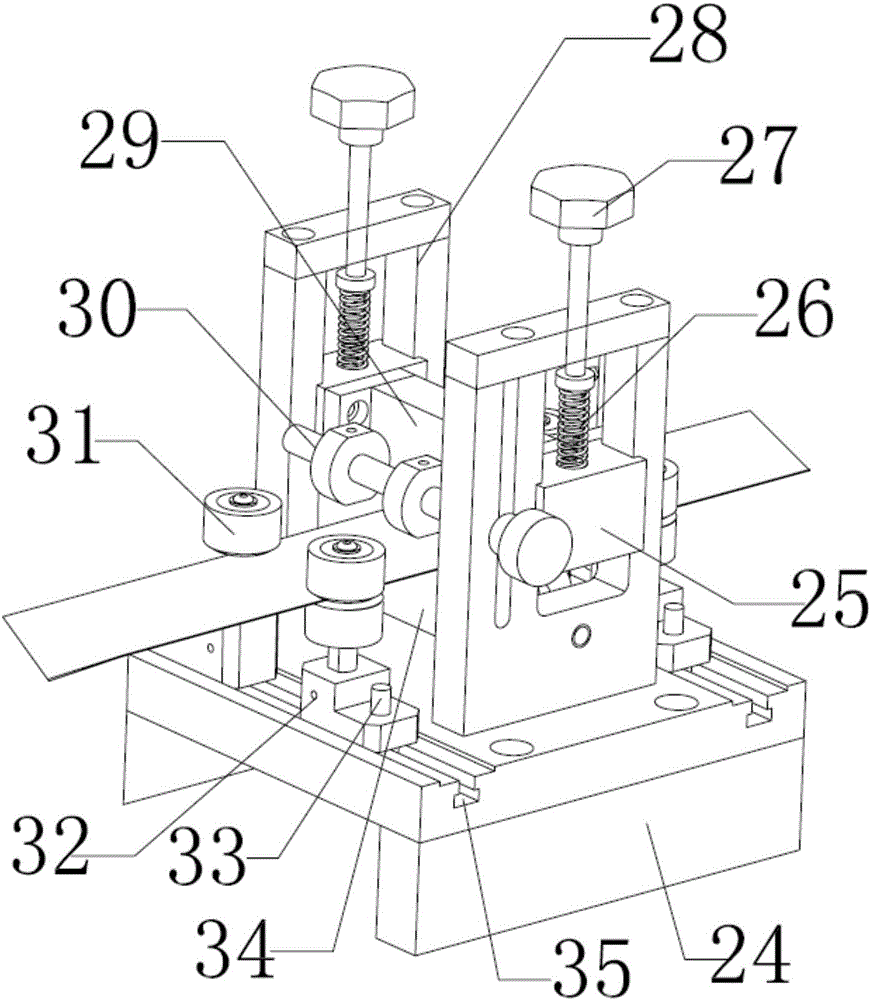

[0032] The steel belt 2 of the repressed product passes through the guide wheel 3, the film sticking device 4, the feeding device 5, the pressing device 6, the two rows of storage wheels 7 and the coding wheel device 12, and then enters the forming machine for rolling forming, and the PE film is rolled along the The film sticking guide device 30 passes through the gap between the pressing block 29 and the roller 34 , and the gap between the pressing block 29 and the rolling wheel 34 can be adjusted by the adjusting screw 27 in the film sticking device 4 . The lower end of the adjusting screw 27 passes through the spring 26 and the slide block 25 slidably installed in the corresponding support 28, and a pressure block 29 is installed between the two slide blocks 25, and the pressure block 29 has a certain amount of elastic expansion and contraction.

[0033] Under normal operation, the conveying device 5 works to convey materials, the rotation of the motor 36 drives the fixed dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com