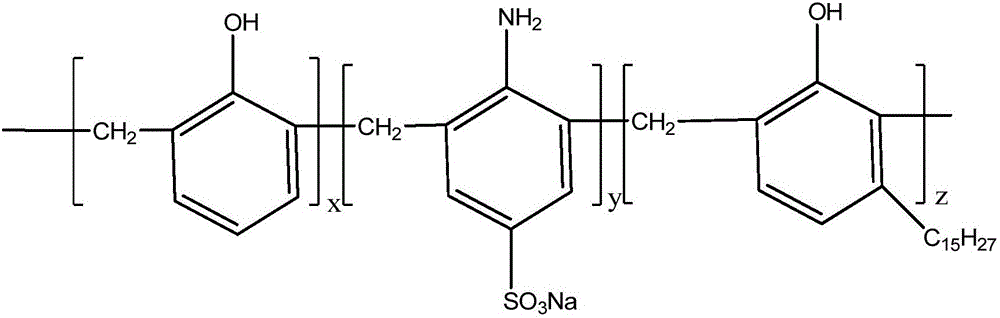

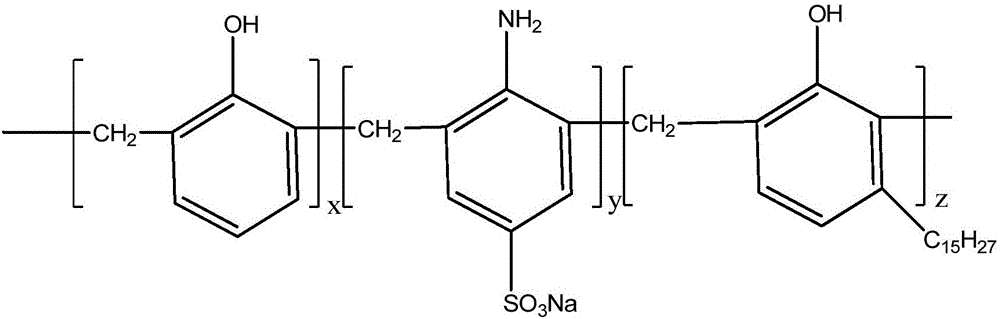

Modified sulfamic acid water-reducing agent and method for preparing same

A technology of sulfamic acid and water reducing agent, applied in the field of building materials, can solve the problems of complicated operation process and high cost, and achieve the effects of reducing cost, low price and improving workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1. Weigh 13.94g of sodium p-aminobenzenesulfonate, 7.37g of phenol and 23.52g of cardanol into a four-necked bottle.

[0024] 2. Weigh 36g of water and add it into a four-necked bottle, raise the temperature to 60°C, stir to dissolve, and adjust the pH value to 9 (using 40% sodium hydroxide solution).

[0025] 3. Continue to heat up to 90° C., slowly add 18.58 g of 37% formaldehyde solution dropwise (the dropping time is controlled within 3 hours), and keep warm for 7 hours after the dropping is completed.

[0026] 4. After the reaction is completed, lower the temperature to 30°C, adjust the pH to about 9, and detect the discharge.

Embodiment 2

[0028] 1. Weigh 13.94g sodium p-aminobenzenesulfonate, 9.25g phenol and 17.52g cardanol into a four-necked bottle.

[0029] 2. Weigh 36g of water and add it into a four-necked bottle, raise the temperature to 60°C, stir to dissolve, and adjust the pH value to 9 (using 40% sodium hydroxide solution).

[0030] 3. Continue to heat up to 90° C., slowly add 18.58 g of 37% formaldehyde solution dropwise (the dropping time is controlled within 3 hours), and keep warm for 7 hours after the dropping is completed.

[0031] 4. After the reaction is completed, lower the temperature to 30°C, adjust the pH to about 9, and detect the discharge.

[0032] When the dosage of products 1 and 2 is 0.5%, the water reducing rate is 20.1% and 20% respectively, and the bleeding rate is 1.4% and 1.6%. And when the dosage of commercially available sulfamic acid water reducer is 0.5%, the water reducing rate is 18.3%, and the bleeding rate is 12.4%. This is due to the introduction of cardanol, which ha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bleeding rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap