Atmospheric corrosion resistant steel for high-strength container and manufacturing method for atmospheric corrosion resistant steel

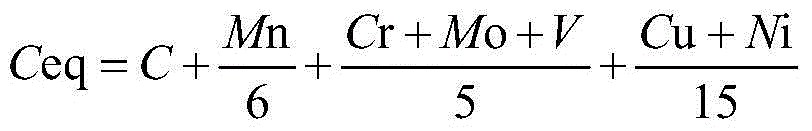

A technology of atmospheric corrosion-resistant steel and its manufacturing method, which is applied in the field of atmospheric corrosion-resistant steel for high-strength containers and its manufacturing, can solve the problems of increasing manufacturing costs, unfavorable steel plate welding performance and low-temperature impact performance, etc., to achieve increased load-bearing capacity, Excellent comprehensive mechanical properties, the effect of strength improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] According to the chemical composition requirements of the steel of the present invention, smelting is carried out in a converter, and then post-furnace refining is carried out to obtain the chemical composition shown in Table 1. The continuous casting billets are sent to the hot rolling production line. The billet heating temperature is 1260 ° C. Two-stage controlled rolling and water cooling after rolling And coiling, the final rolling temperature is 830℃~880℃, and the coiling temperature is 580℃~660℃.

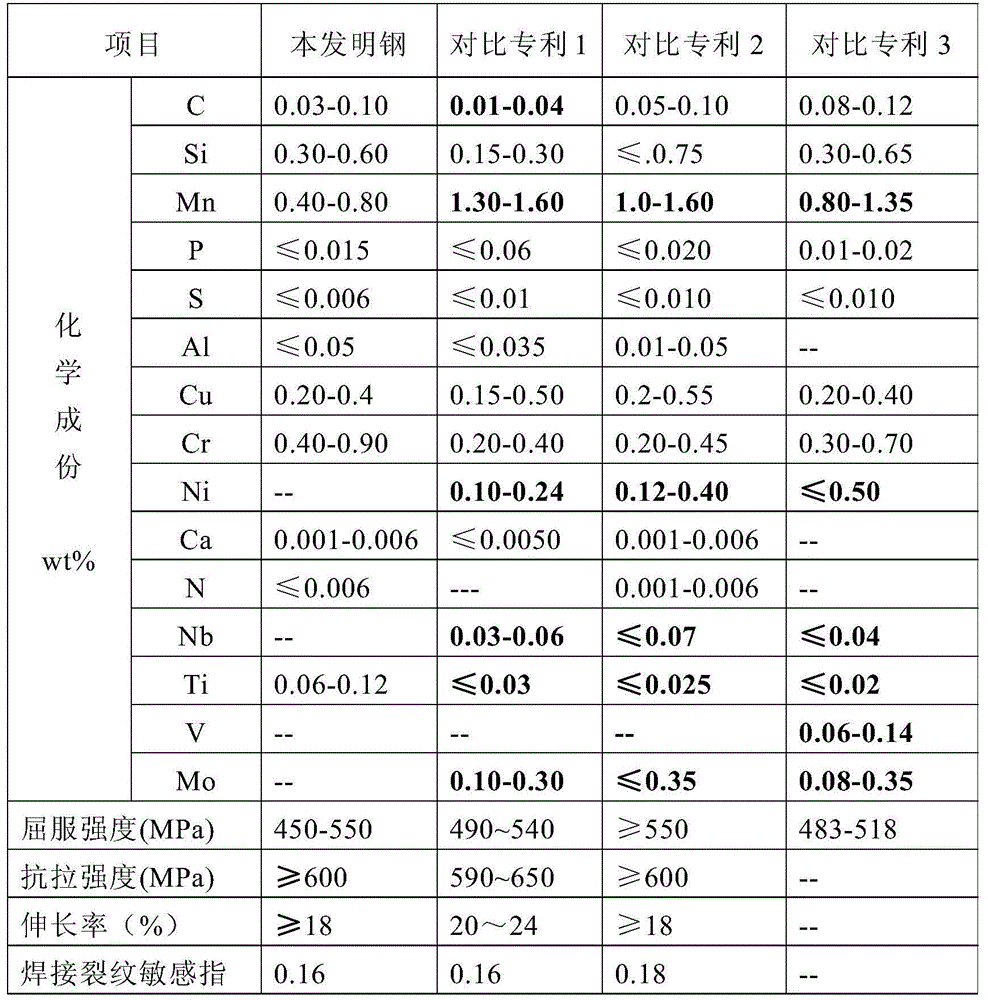

[0050] The mechanical properties of the steel examples of the present invention are shown in Table 1. The chemical composition, mechanical properties, etc. were compared with similar steel types. Among them, the comparison patent 1 is the Chinese patent number ZL200410061112.4, and the comparison patent 2 is the Chinese patent number ZL200510111858.6. Comparative patent 3 is US patent US6056833.

[0051] Table 1 Steel of the present invention and comparison of chemica...

Embodiment 2

[0058] According to the composition requirements of the present invention, the steel of the present invention is smelted on a 500kg vacuum induction furnace in a laboratory. The chemical composition is shown in Table 2, and the manufacturing process is shown in Table 3.

[0059] The billet heating temperature is 1260°C, the final rolling temperature is 830-880°C, accelerated cooling to 580°C-660°C for coiling after rolling, and then air-cooled to room temperature.

[0060] The mechanical properties of the steel of the present invention are shown in Table 4.

[0061] Table 2 steel embodiment of the present invention - chemical composition (wt%)

[0062] Example C Si mn P S Al Cu Cr Ti Ca N 1 0.030 0.32 0.54 0.008 0.004 0.037 0.35 0.60 0.06 0.0021 0.0045 2 0.031 0.39 0.80 0.009 0.003 0.035 0.31 0.90 0.12 0.0038 0.0044 3 0.047 0.32 0.61 0.010 0.003 0.036 0.32 0.49 0.09 0.0029 0.0051 4 0.066 0.30 0.49 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap