Automatic sewing device

A sewing and equipment technology, applied in the field of automatic sewing equipment, can solve the problems of restricting the development of garment processing factories, high defective rate, low labor efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

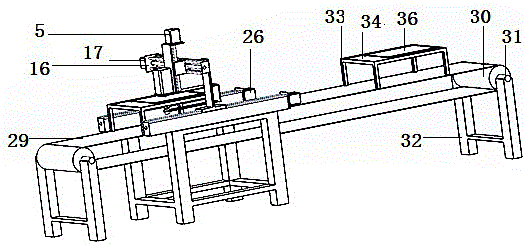

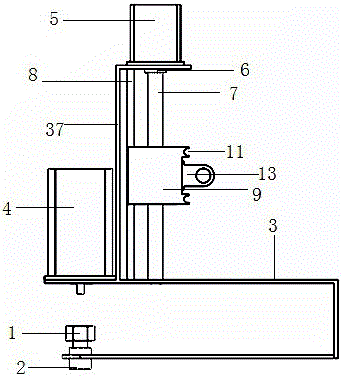

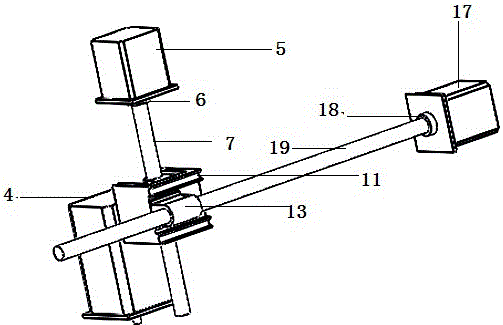

[0025] Specific implementation mode one: combine Figure 1-7 As shown, an automatic sewing device is characterized in that: it includes a bottom thread installer 1, and the bottom thread installer 1 is screw-mounted on the top of the lifter 2; the lifter 2 is installed on the lower end of the head support 3 by screws; the head support 3 The top of the top is welded with a vertical motor support 37; one end of the vertical motor support 37 is equipped with a vertical motion motor 5 by a screw; the vertical motion motor 5 lower end is equipped with a vertical motion leading screw 7 by a vertical motion coupling 6; Head support 3 is provided with vertical motion guide rail 8; Head support 3 is installed on the vertical motion support 9; One end of vertical motion support 9 is provided with two vertical motion guide rail grooves 10; The other end is provided with two lateral motion guide rail grooves 11; Vertical lead screw nut 12 is installed by screw in the middle of vertical mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com