Rotary pipeline connecting system

A connection system and rotary joint technology, applied in the field of rotatable pipeline connection systems, can solve the problems of broken seals, easy fouling on the inner wall, and odor emission, and achieve the effects of preventing water leakage, flexible rotation, and avoiding odors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

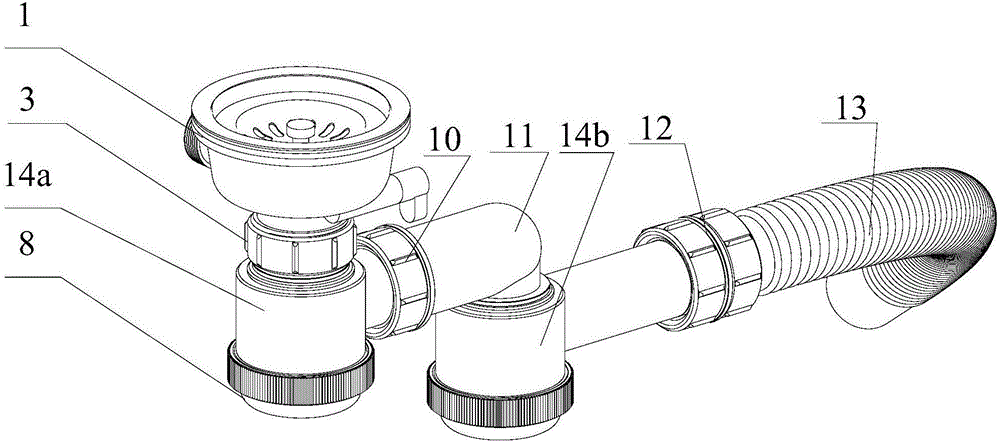

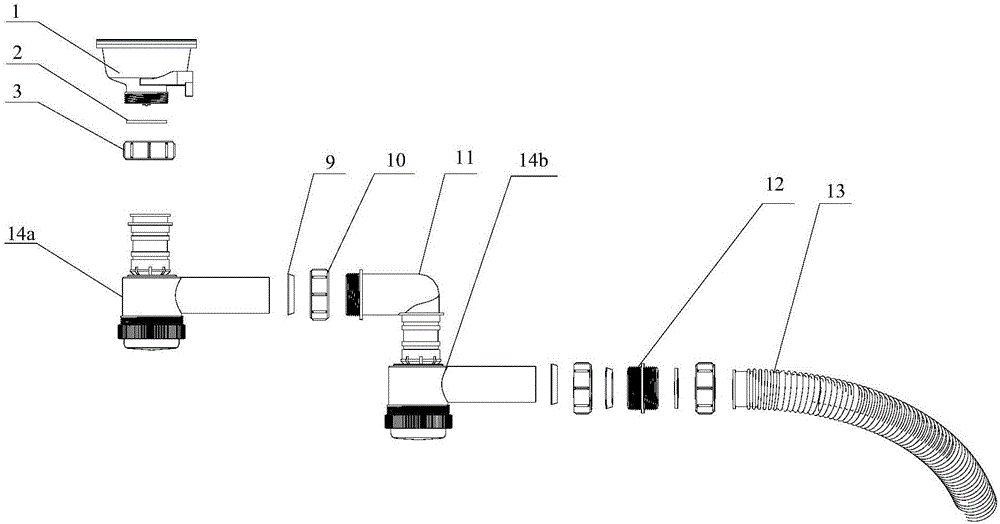

[0028] combine figure 1 and figure 2 As shown, a rotatable pipeline connection system includes two sets of rotary joint assemblies, the rotary joint assembly includes a water trap 6 and a rotatable direct pipe 4 sleeved in the water trap 6;

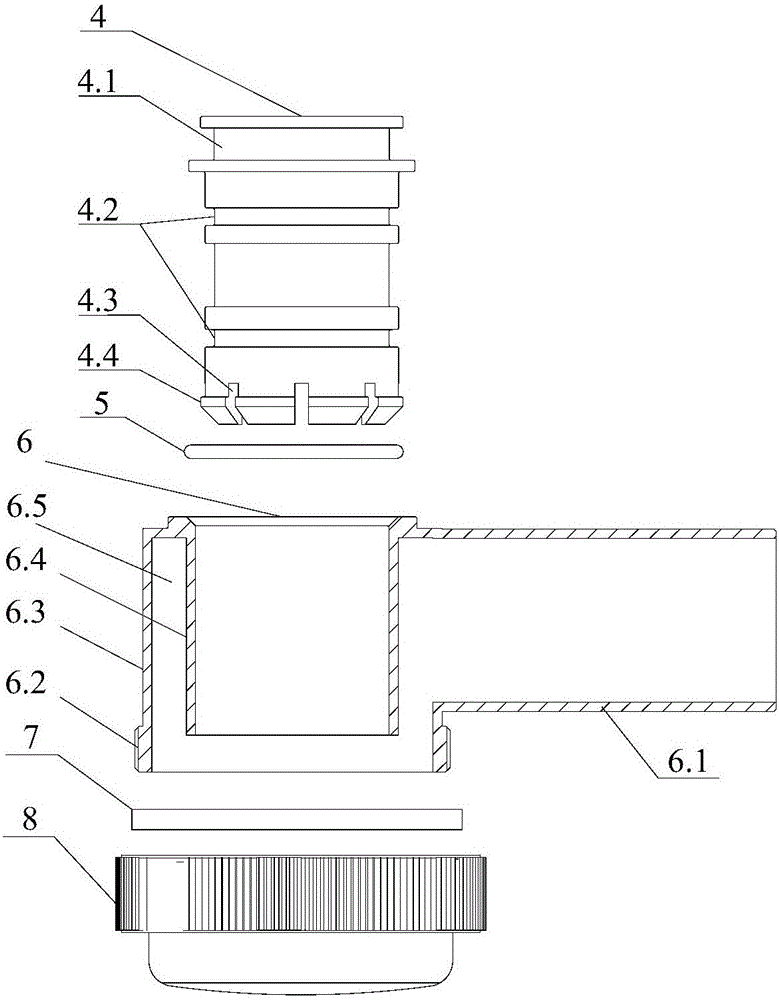

[0029] Wherein, the trap 6 includes a vertical pipe 6.3, a side pipe 6.1, a casing 6.4, a trap head 8, a casing 6.4 is arranged inside the vertical pipe 6.3, and the bottom of the casing 6.4 and the vertical pipe 6.3 correspond to the A "U"-shaped gap 6.5 is formed between the side walls. The upper end of the "U"-shaped gap 6.5 is closed, and the lower end is provided with a trap head 8 that is detachably connected. The "U"-shaped gap 6.5 communicates with the side pipe 6.1; The outer wall of the lower end of the vertical pipe 6.3 of the water trap 6 is provided with a screw thread 6.2 that cooperates with the water trap head 8, and the joint between the water trap head 8 and the water trap 6 is provided with a gasket 7.

[0030] Where...

Embodiment 2

[0034] Such as figure 1 As shown, a rotatable pipeline connection system includes a rotary joint assembly, and the rotary joint assembly includes a water trap 6 and a rotatable direct pipe 4 sleeved in the water trap 6;

[0035] Among them, the trap 6 includes a vertical pipe 6.3, a side pipe 6.1, a casing 6.4, and a trap head 8. The vertical pipe 6.3 is provided with a casing 6.4, and the bottom and side of the casing 6.4 correspond to the vertical pipe 6.3. A "U"-shaped gap 6.5 is formed between the walls, the upper end of the "U"-shaped gap 6.5 is closed, and the lower end is provided with a trap head 8 that is detachably connected, and the "U"-shaped gap 6.5 communicates with the side pipe 6.1; The outer wall of the lower end of the vertical pipe 6.3 of the water trap 6 is provided with a screw thread 6.2 cooperating with the water trap head 8, and a gasket 7 is provided at the connection between the water trap head 8 and the water trap 6.

[0036] Wherein, the upper end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com