System and method for clearing graphite on coke oven riser tube and recovering residual heat of raw coke oven gas

A technology of raw gas and graphite, applied in the steam generation method using heat carrier, heating of coke oven, coke oven, etc., can solve problems such as blockage of raw gas channel by graphite, waste of heat of raw gas, etc., and improve energy utilization rate , improve safety and work efficiency, and reduce labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

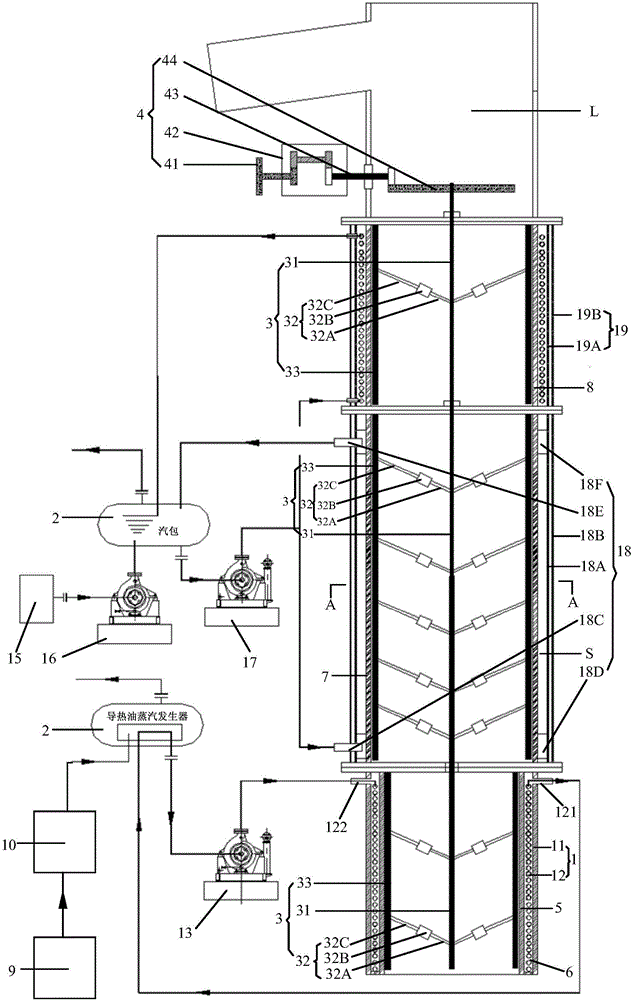

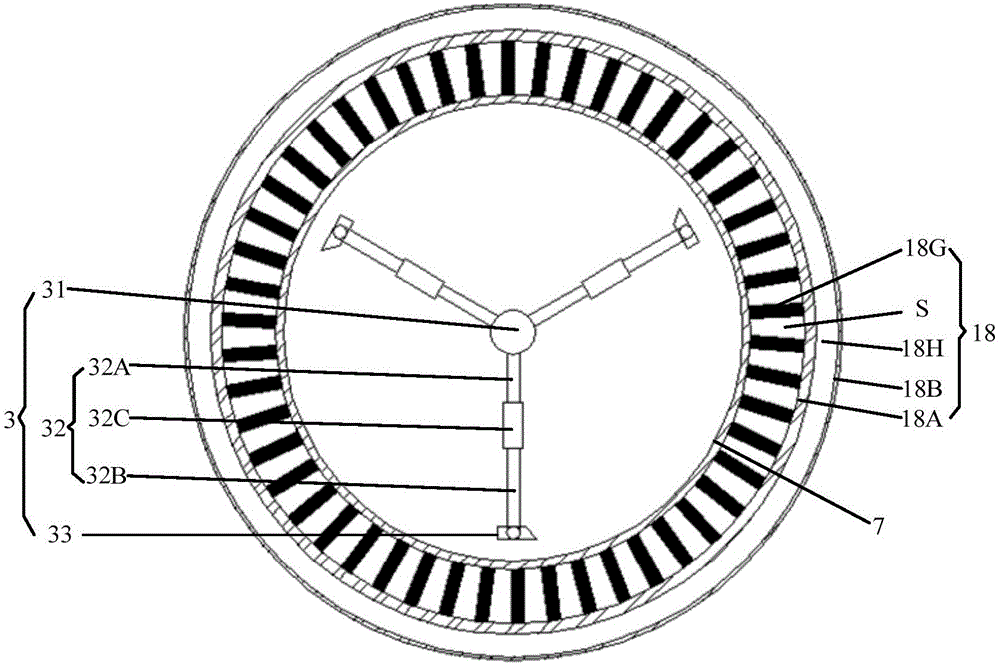

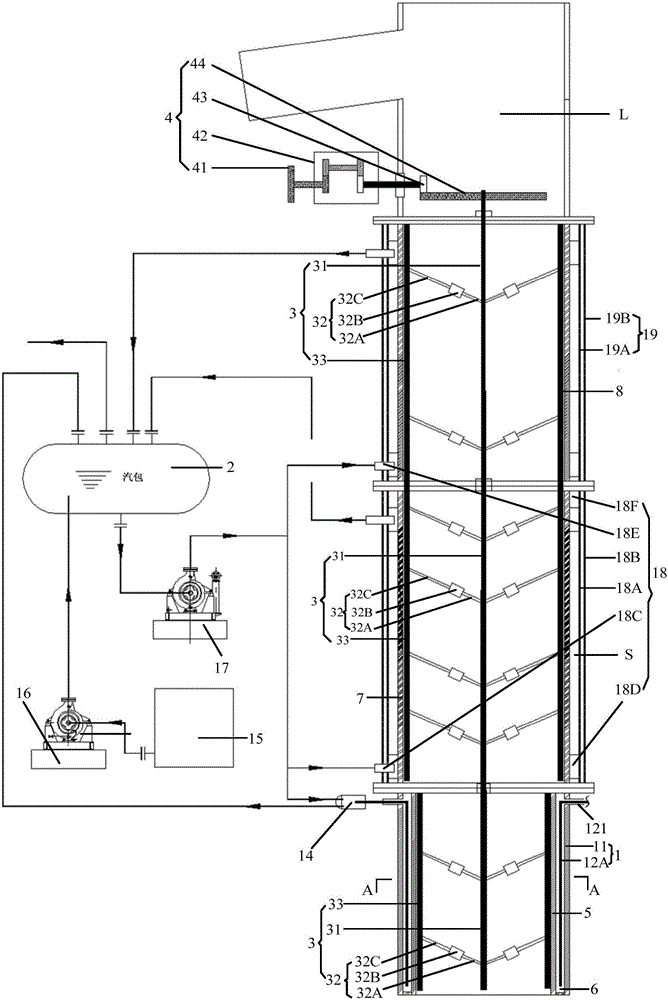

[0050] In order to solve the problems in the prior art that the heat of raw gas is wasted in vain, and the raw gas channel at the root of the riser is blocked by graphite, the embodiment of the present invention provides a system for cleaning the graphite of the coke oven riser and recovering the waste heat of the raw gas ,Such as figure 1 As shown, the system includes a heat exchange device 1 at the root of the riser, a waste heat recovery device 2, a rotating spoiler scraper 3 and a transmission device 4;

[0051] The heat exchange device 1 at the root of the riser includes an outer cylinder 11 and a heat exchanger 12. The outer cylinder 11 is set outside the raw gas passage 5 at the root of the riser and forms an annular space 6 with the outer wall of the raw gas passage 5. The heat exchanger 12 is located in the annular space. In the space 6, a working medium outlet is provided on the outer cylinder 11, and the outlet 121 of the heat exchanger 12 is connected to the waste ...

Embodiment 2

[0084] The embodiment of the present invention provides a method for cleaning the graphite of the coke oven riser pipe and recovering the waste heat of the raw coal gas by using the system in the first embodiment, the method includes:

[0085] Arrange the riser root heat exchange device 1 outside the raw gas passage 5, arrange the rotating spoiler scraper 3 in the inner chamber of the raw gas passage 5, the inner chamber of the straight pipe section 7 of the rising pipe and the inner chamber of the bridge pipe 8, and place the rising pipe The heat exchanger 12 of the root heat exchange device 1 is connected to the waste heat recovery device 2, and the rotating shaft 31 of the rotating spoiler scraper 3 is connected to the transmission device 4;

[0086] The heat exchanger 12 cools and exchanges the heat of the raw gas in the raw gas passage 5, the transmission mechanism drives the rotating shaft 31 of the rotating spoiler scraper 3 to rotate, and the rotating shaft 31 drives th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap