Radiating pipe base and manufacturing method thereof

A manufacturing method and heat pipe technology, applied in heat exchange equipment, heat exchanger shell, heat exchanger fixing and other directions, can solve the problem of affecting heat dissipation effect, inconvenient movement, unfavorable heat sink, heat pipe cleaning, replacement or maintenance, etc. problem, to achieve the effect of high-efficiency mass production and convenient assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

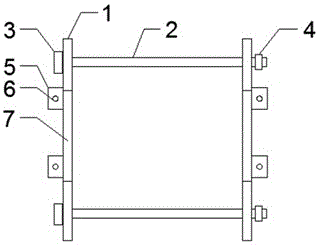

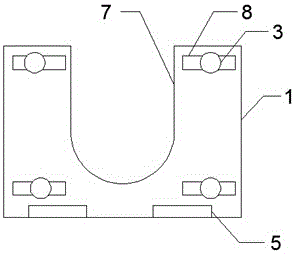

[0023] A heat dissipation pipe seat, comprising a square plate 1 and a straight rod 2, a U-shaped groove 7 is formed on the upper part of one side surface of the square plate 1, and a U-shaped groove 7 is formed on the left and right sides of the U-shaped groove 7 on the side surface of the square plate 1 There is a pair of rectangular bar holes 8, the lower part of one side of the square plate 1 is brazed with a fixing seat 5, the upper surface of the fixing seat 5 is provided with a mounting hole 6, and one end of the straight rod 2 is inserted into the rectangular bar hole 8, and one end of the straight rod 2 is fixedly connected with a round cake 3, the outside of the other end of the straight rod 2 is provided with an external thread and an anti-skid nut 4 is installed, and the diameter of the straight rod 2 is smaller than the width of the rectangular hole 8 , the diameter of the round cake 3 is greater than the width of the rectangular hole 8, the number of the square pl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com