Automatic calibration method of sensor and batch calibration device

An automatic calibration, sensor technology, applied in the direction of automatic recalibration, test/calibration device, measurement device, etc., can solve the problems of complicated processing process and large workload, and achieve the effect of convenient expansion and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

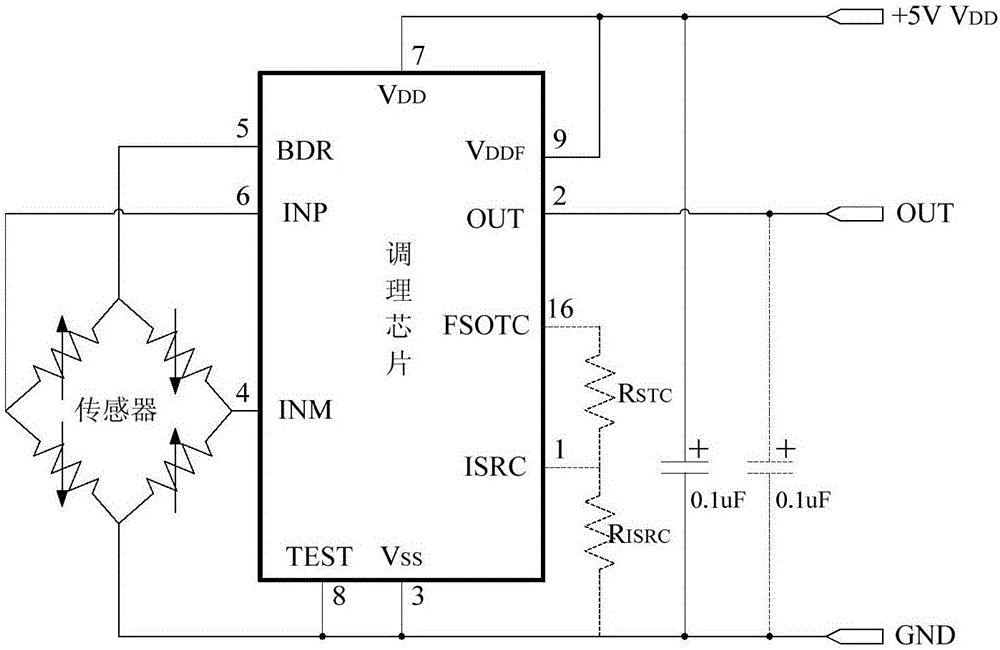

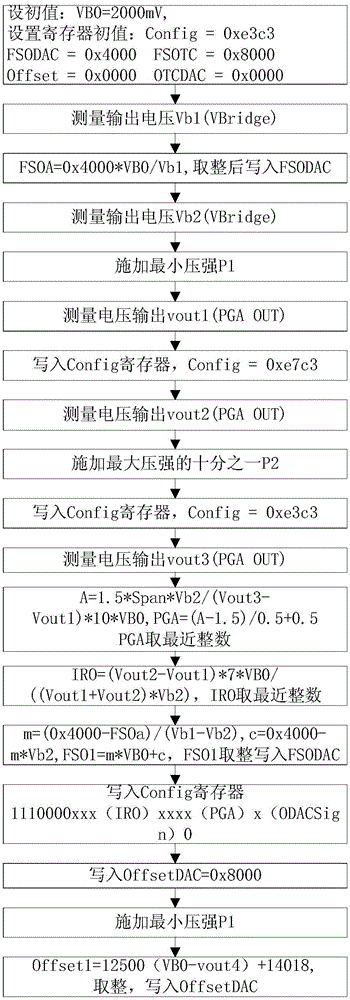

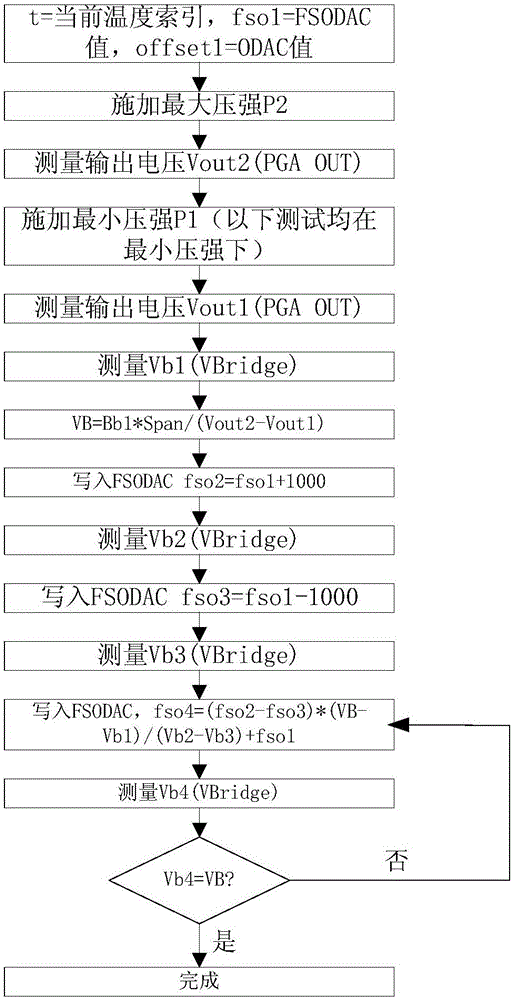

[0041] The sensor automatic calibration method of the present invention mainly realizes the automatic calibration of the sensor through two major links of pre-calibration and main calibration.

[0042] The pre-calibration stage calculates and determines the configuration parameters of the sensor conditioning chip; the main calibration is based on the pre-calibration, the sensor output is stabilized at the required output value by adjusting the compensation amount, and the calibration compensation value is obtained by using the approximation algorithm.

[0043] Taking the pressure sensor and considering the temperature variable factor as an example, a specific example of an automatic batch calibration method is given below.

[0044] like Figure 1 to Figure 4 As shown, the pressure sensor automatic batch calibration method includes the following steps:

[0045] Step 1] On the premise of confirming that the sensor communication is normal, perform the pre-calibration operation. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com