A turbocharger testing equipment and method thereof

A turbocharger and test equipment technology, applied in the testing of machine/structural components, testing of mechanical components, instruments, etc., can solve problems such as inability to accurately simulate the practical working conditions of turbochargers, inconsistent output parameters, etc., and achieve The detection scheme is simple, the effect of improving production and improving detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

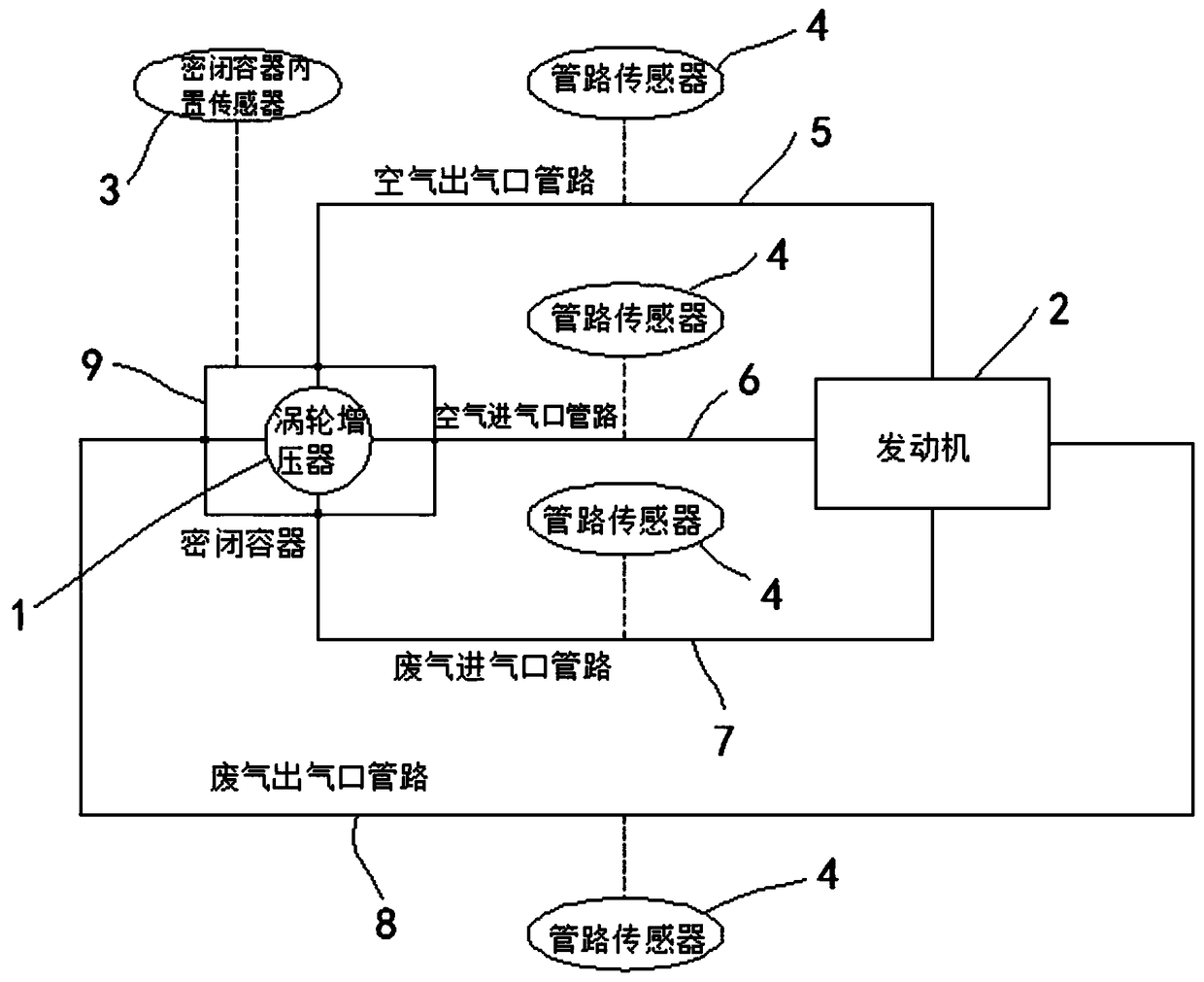

[0032] The simulated exhaust gas generation system uses the simulated exhaust gas generation system to generate exhaust gas of different temperatures and compositions produced under various operating conditions of the engine, or the exhaust gas of the working engine is sent into the turbocharger, and the exhaust gas of each inlet and outlet of the turbocharger is detected air pressure, temperature and other parameters, use the computer to judge its airtightness and various performances; each test data of the turbocharger is stored in the computer, when a new turbocharger is tested, the test results The data will be compared with the data obtained from the previous test, and the basis standard for turbocharger performance judgment will be continuously revised according to the comparison results, so that the turbocharger performance judgment results obtained by this testing method will tend to be stable and accurate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com