Sealing mechanism for rock mass shearing and seepage test and method thereof

A technology of sealing mechanism and rock mass, applied in the direction of permeability/surface area analysis, suspension and porous material analysis, measuring device, etc., to achieve good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Below in conjunction with accompanying drawing and embodiment describe in detail:

[0044] 1. Sealing mechanism for rock mass shear and seepage tests

[0045] 1. Overall

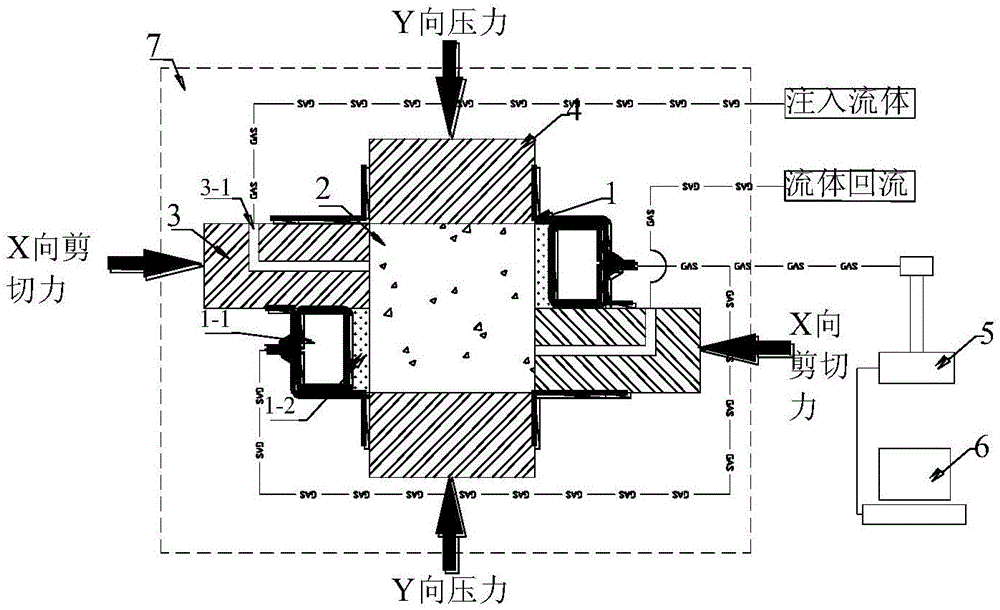

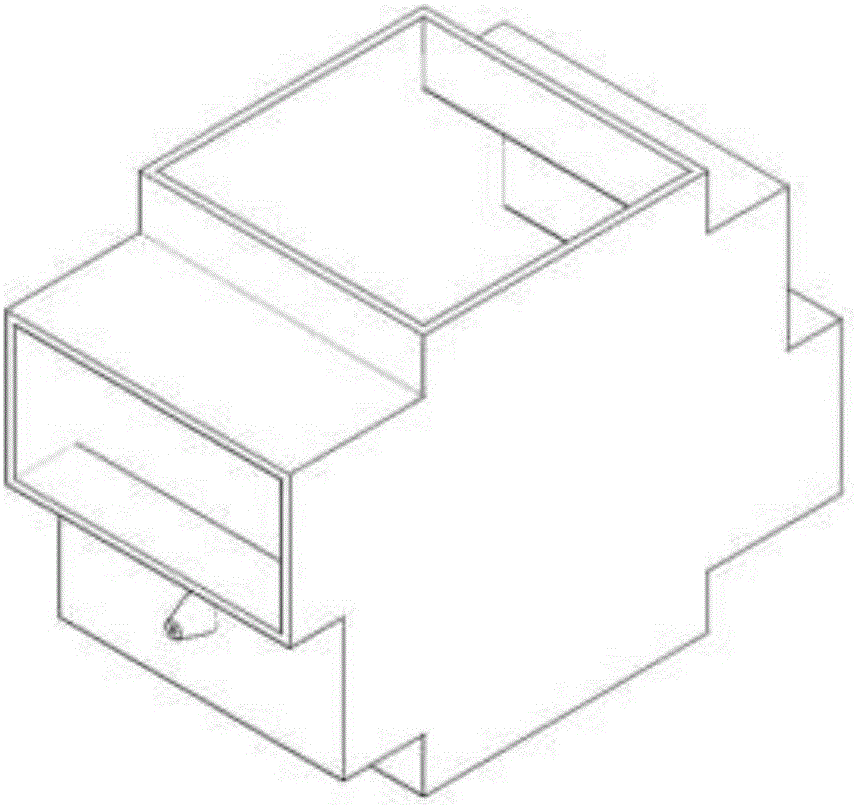

[0046] like figure 1 , the sealing mechanism includes a rock mass shearing and seepage test device composed of a sealing rubber sleeve 1, a rock sample 2, a shear plate 3, a normal pressure plate 4, a confining pressure tracking pump 5, a computer 6 and a confining pressure chamber 7;

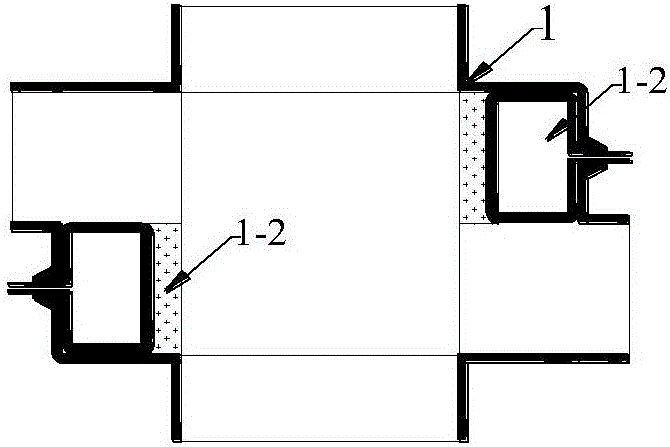

[0047] A sealing rubber sleeve 1, a deformation capsule 1-1 and a deformation partition 1-2 are provided;

[0048] Its location and connection relationship are:

[0049] The sealing rubber sleeve 1 is placed in the center of the confining pressure chamber 7, the rock sample 2 is placed in the center of the sealing rubber sleeve 1, and two shear plates 3 pass through the left and right sides of the sealing rubber sleeve 1 from left and right to press To tighten the rock sample 2, two normal pressure plates 4 respect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com