Method for deteting durability of overflow brick

A detection method and overflow brick technology, which are applied in measuring devices, weather resistance/light resistance/corrosion resistance, instruments, etc., can solve the problems of no measurement overflow bricks, no detection method, etc., and achieve high measurement accuracy and reliability. Reduce errors, good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

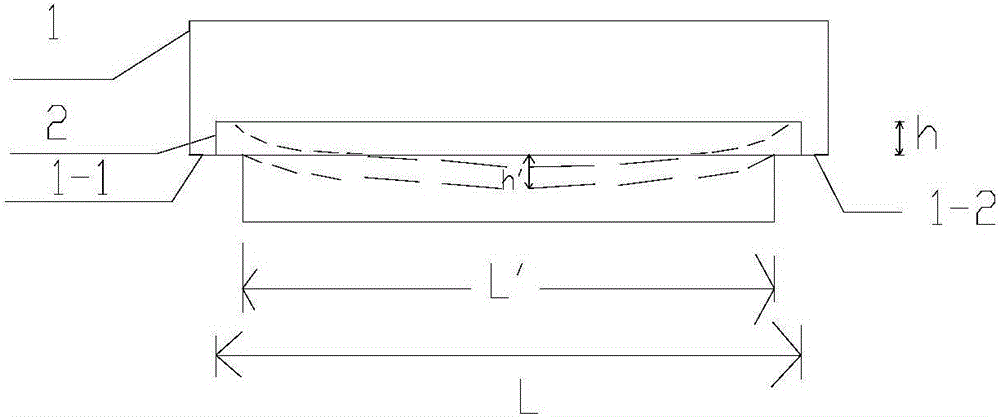

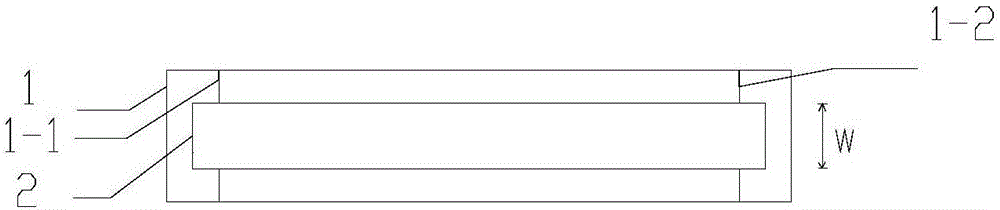

Method used

Image

Examples

Embodiment 1

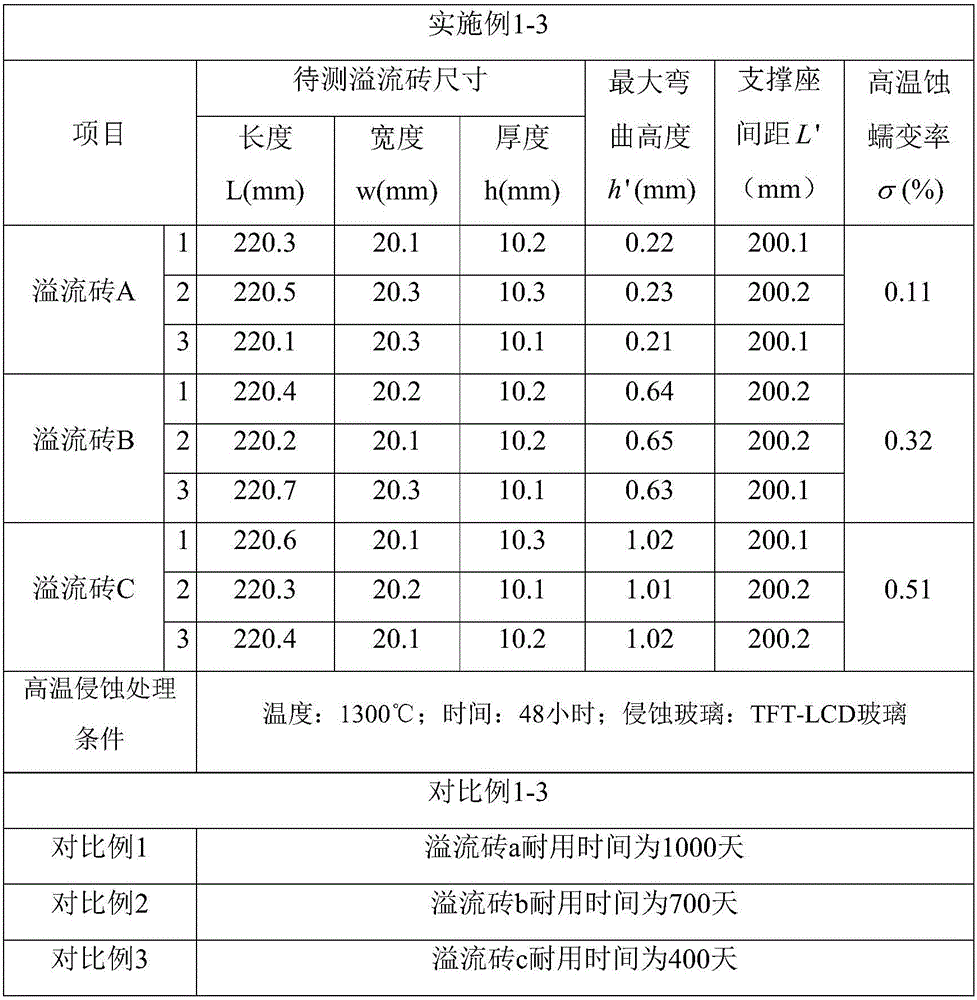

[0041] Make three overflow bricks A to be tested and detect three times, and take the average value of the test results. The composition of overflow brick A is: ZrO 2 67.9%, SiO 2 31.2%, TiO 2 0.5%, impurity 0.4%; specific testing conditions and testing results are shown in Table 1.

Embodiment 2

[0043] Make three overflow bricks B to be tested and detect three times, and the test results are averaged. The composition of overflow brick B is: ZrO 2 66.6%, SiO 2 32.8%, TiO 2 0.2%, impurity 0.4%; specific testing conditions and testing results are shown in Table 1.

Embodiment 3

[0045] Make three overflow bricks C to be tested and detect three times, and the test results are averaged. The composition of overflow brick C is: ZrO 2 64.4%, SiO2 34.6%, TiO 2 0.6%, impurity 0.4%; specific testing conditions and testing results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com