Parameter optimization method for suspension system of power assembly

A powertrain and suspension system technology, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve problems such as low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

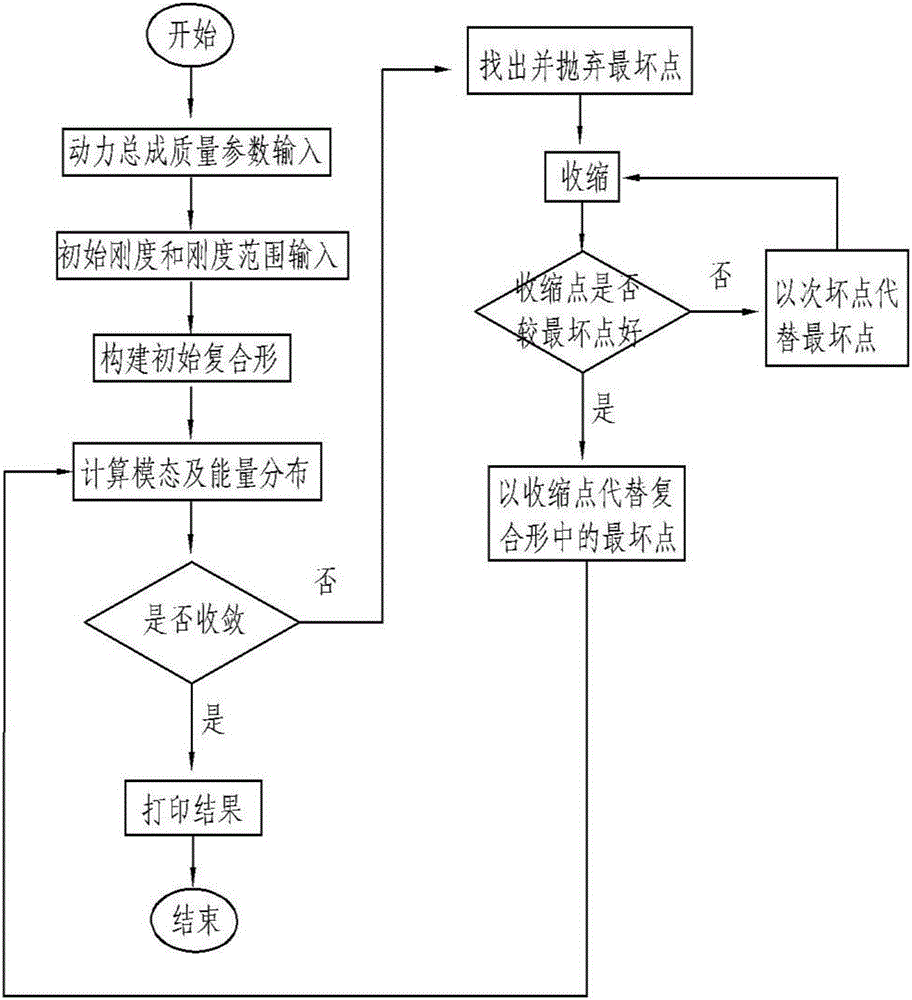

[0067] see figure 1 , the present invention discloses a parameter optimization method for a powertrain mount system, the parameter optimization method comprising:

[0068] [Step 1] The formation steps of the optimization function;

[0069] In the feasible region, the component has an initial composite shape with n vertices; compare the objective function values of each vertex of the composite shape, find out the point with the largest objective function value, that is, the worst point, and remove it; then follow the set rule Construct a new composite shape until the calculation converges;

[0070] The set law adopts the contraction method. No matter how it changes, the new vertex is still in the design space. It is only necessary to judge whether the new vertex is better than the worst point; the calculation method is as follows:

[0071] Xk=Xb+β*(Xh-Xb)

[0072] Among them, Xk is the contraction point, that is, the new point, β is the contraction coefficient; Xb is the l...

Embodiment 2

[0093] The experimental data of this embodiment are as follows:

[0094] Powertrain Quality Parameters

[0095] m Ix Iy Iz Ixy Iyz Ixz 130.8 6.2617 3.1545 5.4325 -0.6048 0.6924 -0.1837

[0096] Original Design Mounting Rigidity

[0097] direction k Ky Kz left mount 150 40 130 right mount 150 40 130 rear suspension 120 40 40

[0098] suspension position

[0099]

[0100]

[0101] Mode and energy distribution calculated from initial stiffness

[0102] 10.739Hz 5.8411Hz 8.8764Hz 17.4626Hz 13.5709Hz 20.2671Hz 0.9568 0.0004 0.0056 0.0001 0.0179 0.0192 0.0007 0.9975 0.0000 0.0000 0.0001 0.0018 0.0112 0.0000 0.9268 0.0110 0.0506 0.0004 0.0009 -0.0000 0.0047 0.9773 0.0171 0.0001 0.0164 -0.0000 0.0632 0.0086 0.8990 0.0127 0.0140 0.0021 -0.0003 0.0030 0.0153 0.9659

[0103] It can be seen from the results that its decoupli...

Embodiment 3

[0109] A method for optimizing parameters of a powertrain mount system, the parameter optimization method comprising:

[0110] Step 1, the formation step of the optimization function;

[0111] In the feasible region, the component has an initial composite shape with n vertices; compare the objective function values of each vertex of the composite shape, find out the point with the largest objective function value, that is, the worst point, and remove it; then follow the set rule Construct a new composite shape until the calculation converges;

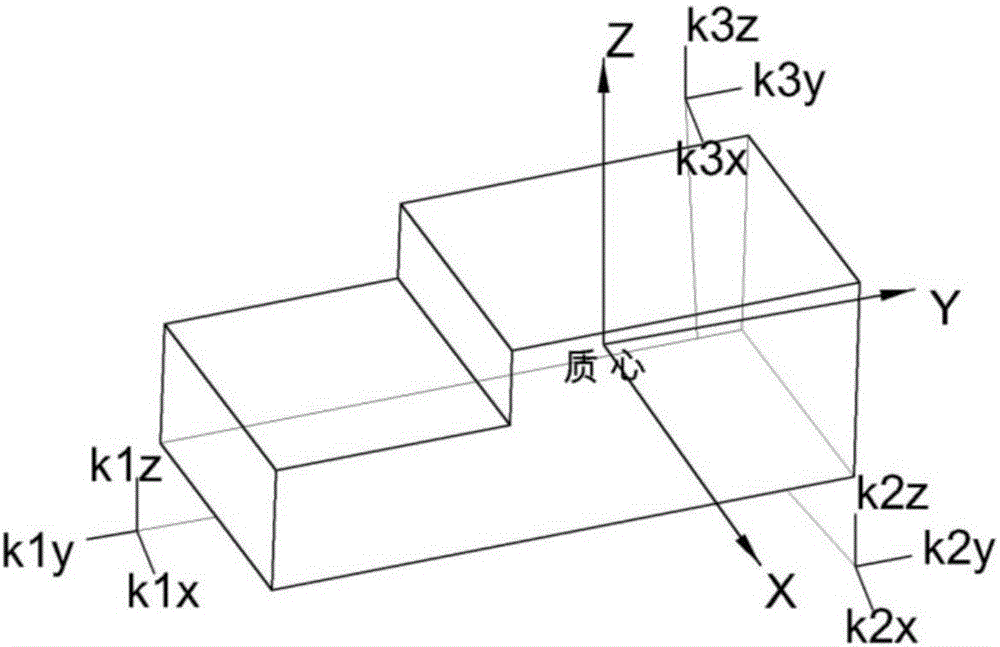

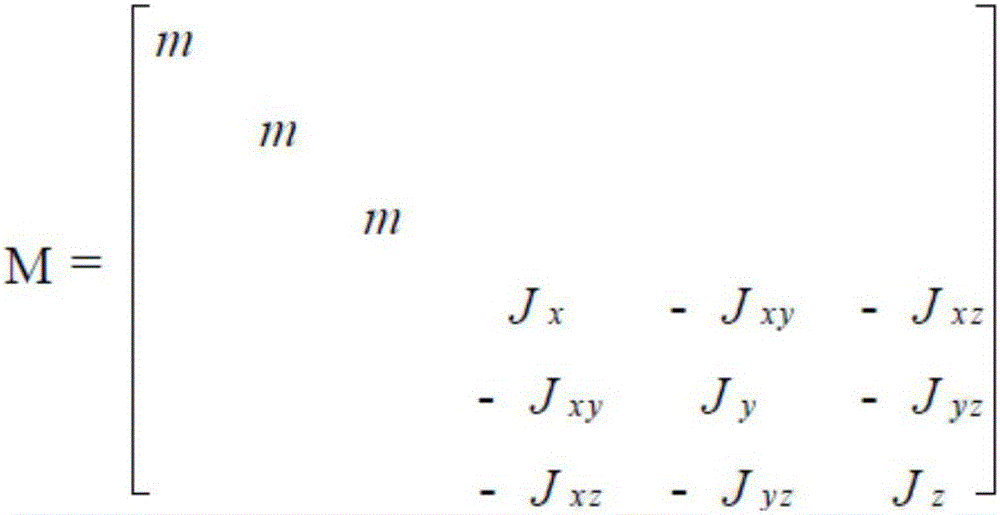

[0112] Step 2. Calculation steps of the natural frequency and decoupling rate of the powertrain mount system;

[0113] The powertrain is regarded as a rigid body with 6 degrees of freedom, its characteristics include the position of the powertrain, the quality parameters of the powertrain, and a coordinate system is established at its center of mass, the x-axis points to the rear of the car, and the y-direction points to the front of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com