Ore dressing plant cylinder thickener calculating method capable of ensuring overflow quality and underflow storage capacity

A technology of storage capacity and thickener, which is applied in the field of cylindrical thickener computing in mineral processing plants, can solve the problems of small thickener depth, no calculation, and no storage capacity of cylindrical thickeners, and achieves the effect of avoiding estimation and blind enlargement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] The copper oxide concentrate in a dressing plant has been tested to have a settling velocity of 0.02 mm / s and a feed concentration of 20%. Settling and compressing in a graduated cylinder for 18 hours can yield a sediment with an average concentration of 60%. The true specific gravity is 3, the maximum dry weight of concentrated ore processed per day is 210 tons per day, and the underflow is stopped for 6 hours every day. Try to choose and calculate the required depth of the concentrator.

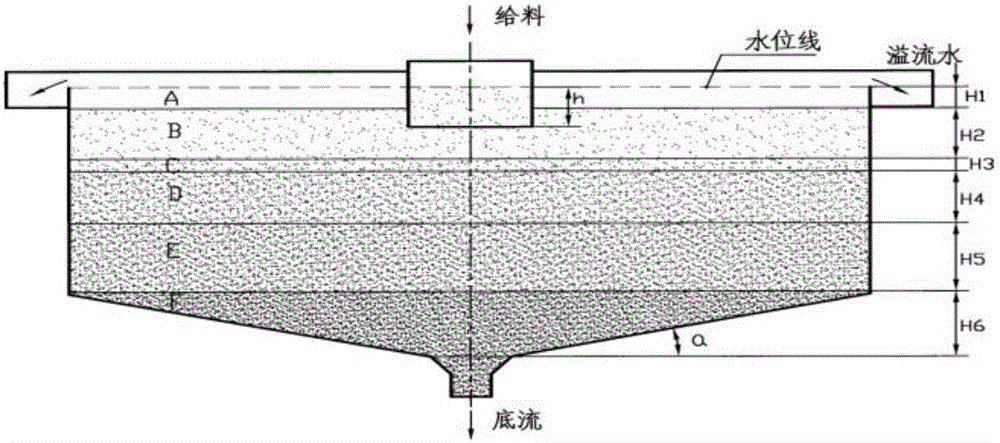

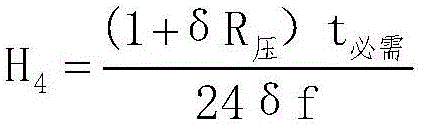

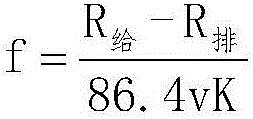

[0074] Such as figure 1 As shown, (1) The calculation requires the area and diameter of the cylindrical thickener

[0075] Q=210 tons / day=0.00243 tons / second

[0076]

[0077]

[0078] V=0.02 mm / s

[0079] K takes 0.9

[0080] δ=3 tons / meter 3

[0081] t 必需 = 18 hours

[0082] t 储存 = 6 hours

[0083] α takes 12°

[0084] thus,

[0085]

[0086] Required settlement area

[0087] F=Qf=210*2.14=449.4 (m 2 )

[0088] Choose a thickener

[0089] Need cylindrical th...

Embodiment 2

[0097] The copper oxide concentrate in a dressing plant has been tested to have a settling velocity of 0.02 mm / s, a feed concentration of 20%, a minimum feed concentration of 15%, and an average concentration of 60% after settling and compressing in a graduated cylinder for 18 hours. The real specific gravity of the copper concentrate is 3, and the maximum dry weight of the concentrate is 210 tons per day. The filtration operation is performed every day, and the production is 6 hours per shift. Try to choose and calculate the depth of the concentrator required.

[0098] Such as figure 1 As shown, (1) The calculation requires the area and diameter of the cylindrical thickener

[0099] Q=210 tons / day=0.00243 tons / second

[0100]

[0101]

[0102] V=0.02 mm / s

[0103] K takes 0.9

[0104] δ=3 tons / meter 3

[0105] t 必需 = 18 hours

[0106] t 储存 = 24-1*6 = 18 hours

[0107] α takes 12°

[0108] thus,

[0109]

[0110] Required settlement area

[0111] F=Qf=210*...

Embodiment 3

[0121] The copper oxide concentrate in a dressing plant has been tested to have a settling velocity of 0.02 mm / s, a feed concentration of 20%, a minimum feed concentration of 15%, and an average concentration of 60% after settling and compressing in a graduated cylinder for 18 hours. The real specific gravity of the copper concentrate is 3, and the maximum dry weight of the concentrate is 210 tons per day. The filtration operation is carried out in one shift per day, and the production time per shift is 6 hours. The maximum time required for filtration overhaul and transformation is 48 hours. Try to select and calculate the required thickener depth.

[0122] Such as figure 1 As shown, (1) The calculation requires the area and diameter of the cylindrical thickener

[0123] Q=210 tons / day=0.00243 tons / second

[0124]

[0125]

[0126] V=0.02 mm / s

[0127] K takes 0.9

[0128] δ=3 tons / meter 3

[0129] t 必需 = 18 hours

[0130] t 储存 =24-1*6+48=66 hours

[0131] α t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com