Wafer transmission device

A transmission device and chip technology, applied in the direction of transportation and packaging, conveyor objects, electrical components, etc., can solve problems such as uneven distribution of adsorption force, shorten the airflow transmission path, improve adsorption force, and improve the uniformity of adsorption force distribution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

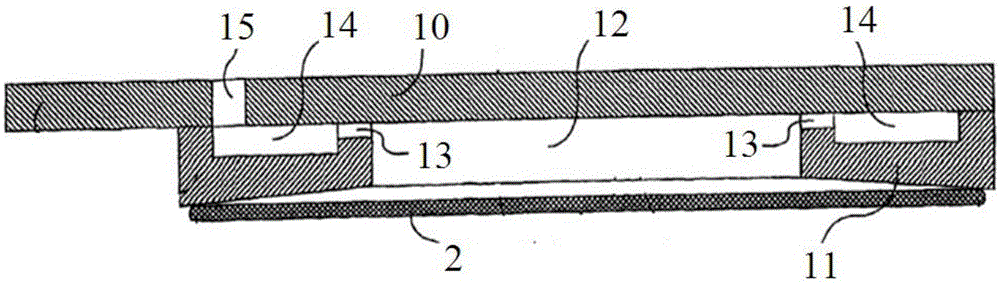

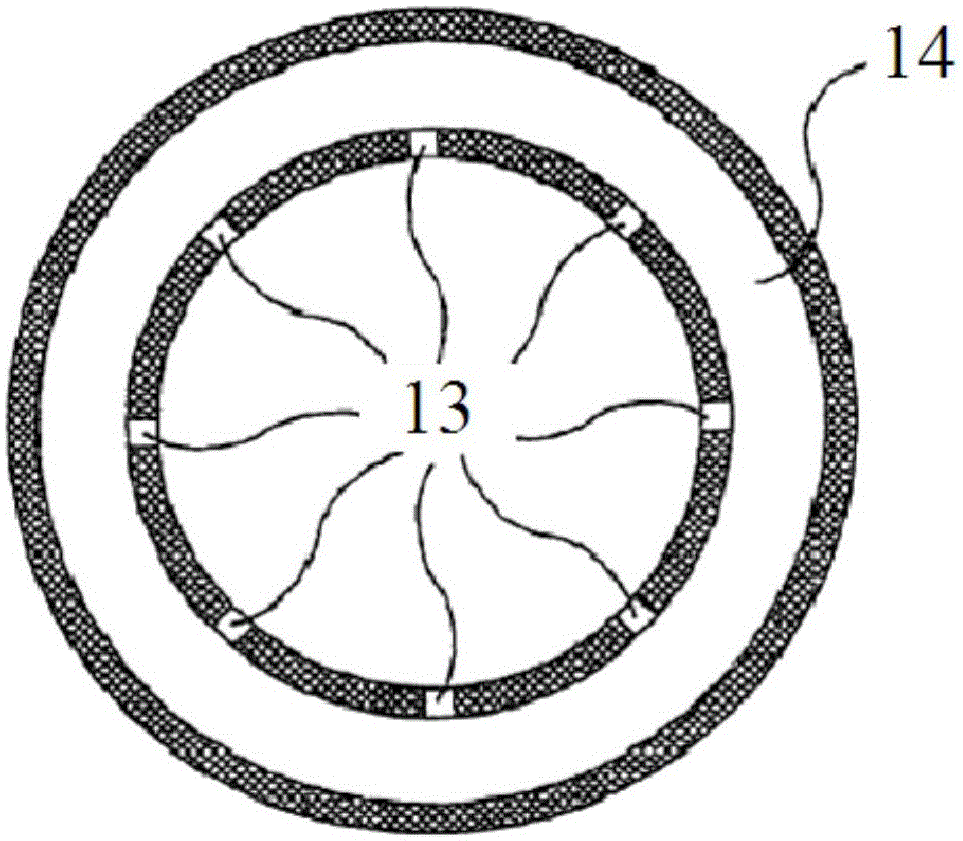

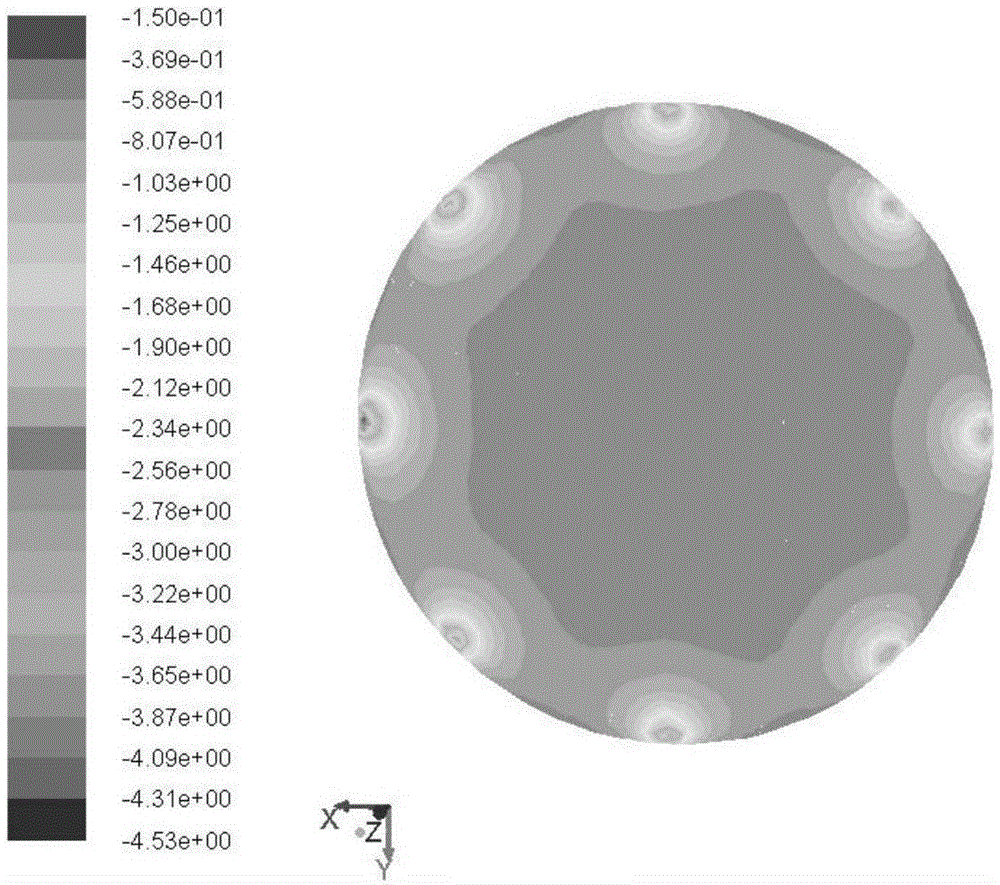

[0029] In order to enable those skilled in the art to better understand the technical solution of the present invention, the wafer transfer device provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

[0030] Please also refer to Figures 4A-4D , the wafer transfer device provided by the embodiment of the present invention includes a plate body, which includes an upper plate 21 and a lower plate 22, wherein the upper plate 21 is a flat plate; grooves are formed on the upper surface of the lower plate 22, and the upper plate 21 and the lower plate 22 When the lower board 22 is docked, the groove and the lower surface of the upper board 21 form an air pumping cavity 23 .

[0031] Moreover, the lower surface of the lower plate 22 is a concave surface 221 , which is used for absorbing the wafer and is only in contact with the edge area of the wafer surface, while the central area of the wafer surface is not in conta...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap