Battery diaphragm with three cellular structures and adopted pore-forming agents and extraction agents

A technology of microporous structure and battery diaphragm, which is applied in the direction of secondary batteries, structural parts, battery pack parts, etc., and can solve the problems of low porosity and air permeability of battery diaphragm, affecting the performance of battery diaphragm, and poor controllability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0164] The composition used to prepare three kinds of microporous structure battery diaphragms comprises the following components by weight:

[0165]

[0166] in,

[0167] The number average molecular weight of high molecular polyethylene is 500,000,

[0168] The number average molecular weight of UHMWPE is 1.4 million,

[0169] The average molecular weight of white oil is 200,

[0170] The particle size of the nano-magnesium chloride is 50-70nm.

[0171]Three kinds of microporous structure battery separators were prepared according to the following methods:

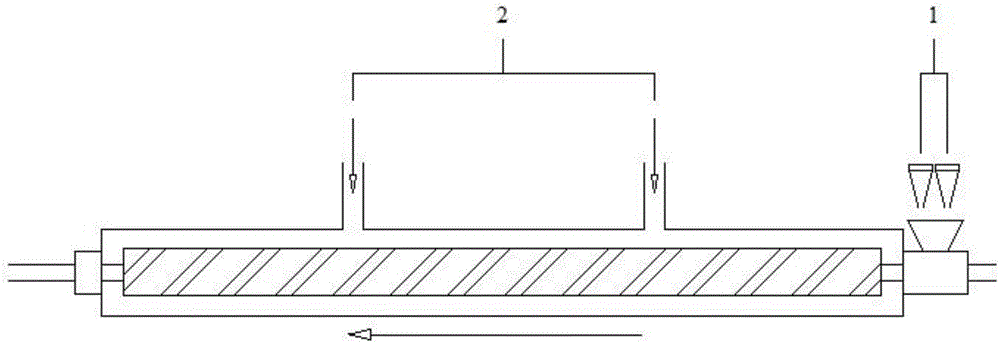

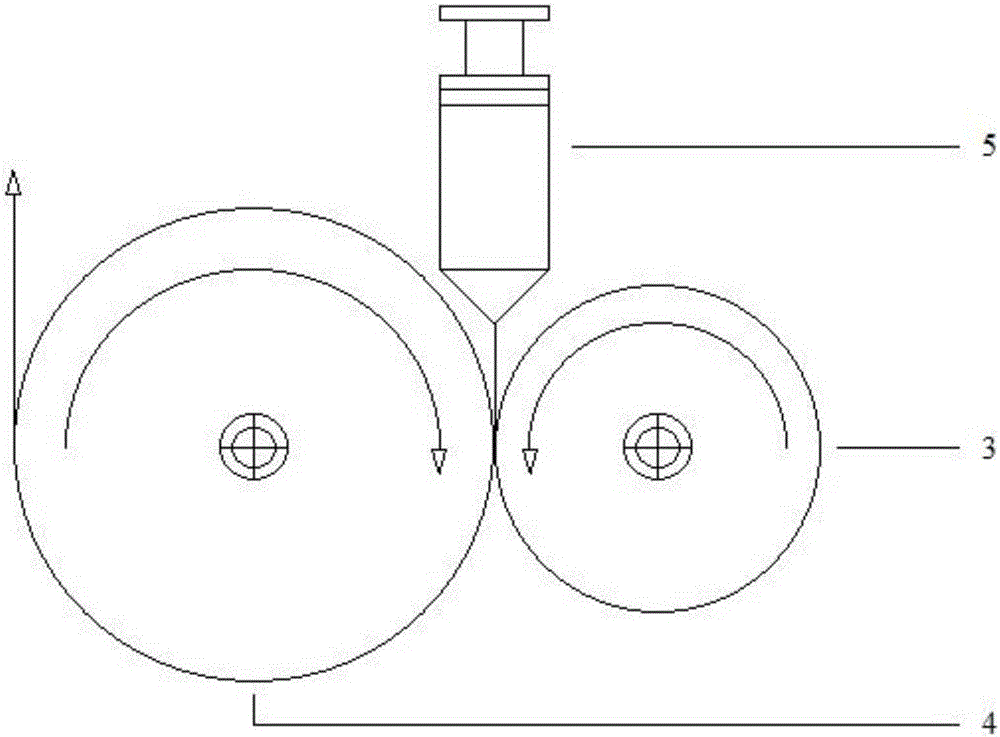

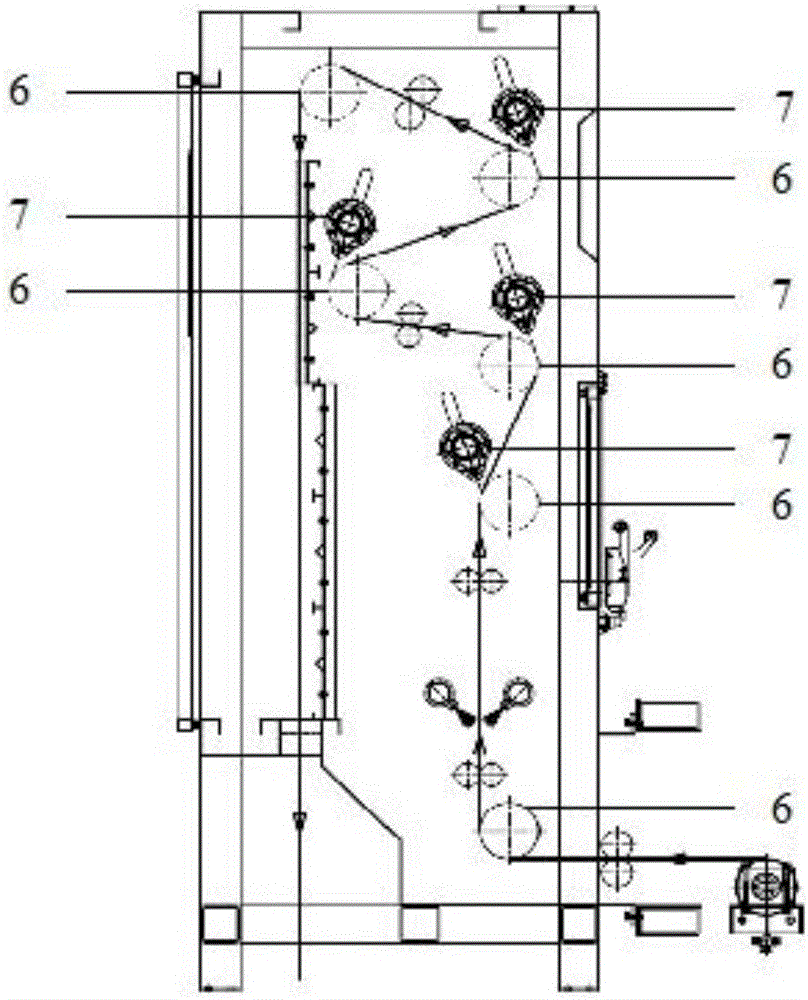

[0172] Step 1), extrusion: mix high molecular weight polyethylene and magnesium chloride nanoparticles uniformly, and mix ultra high molecular weight polyethylene, 4,4-thiobis(6-tert-butyl m-cresol), 2,4-dihydroxy Benzophenone, sodium stearyl quaternary ammonium and Tween 80 are mixed evenly, and the above two mixtures are respectively put into the extruder to be heated and melted through two polyethylene composit...

Embodiment 2

[0179] The composition used to prepare three kinds of microporous structure battery diaphragms comprises the following components by weight:

[0180]

[0181] in,

[0182] The number average molecular weight of high molecular weight polyethylene is 300,000,

[0183] The number average molecular weight of UHMWPE is 1.3 million,

[0184] The average molecular weight of white oil is 180,

[0185] The particle size of the nano-magnesium chloride is 60-90nm.

[0186] Three kinds of microporous structure battery separators were prepared according to the following methods:

[0187] Step 1), extrusion: mix high molecular polyethylene and magnesium chloride nanoparticles evenly, and ultra high molecular polyethylene, 3,5-di-tert-butyl-4-hydroxytoluene, 4-benzoyloxy-2, 2,6,6-Tetramethylpiperidine, octadecyl quaternary ammonium sodium and lauric acid are mixed evenly, and the above two mixtures are respectively fed into the extruder from two polyethylene composition feed ports to ...

Embodiment 3

[0194] The method used in this example is similar to the method used in Example 2, the only difference being that the compositions used to prepare three kinds of microporous structure battery separators include the following components by weight:

[0195]

[0196] in,

[0197] The number average molecular weight of high molecular polyethylene is 400,000,

[0198] The number average molecular weight of UHMWPE is 1.4 million.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap