(Splitting/combining) upgrading connector used in new round of rural power grid upgrading project

A technology for connectors and agricultural power grids, applied in multi-conductor connectors, connections, conductive connections, etc., can solve problems such as difficult operation by operators, economic losses for users across the line, unsafe economic losses and major accidents, etc. Fast, easy to operate and quick effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

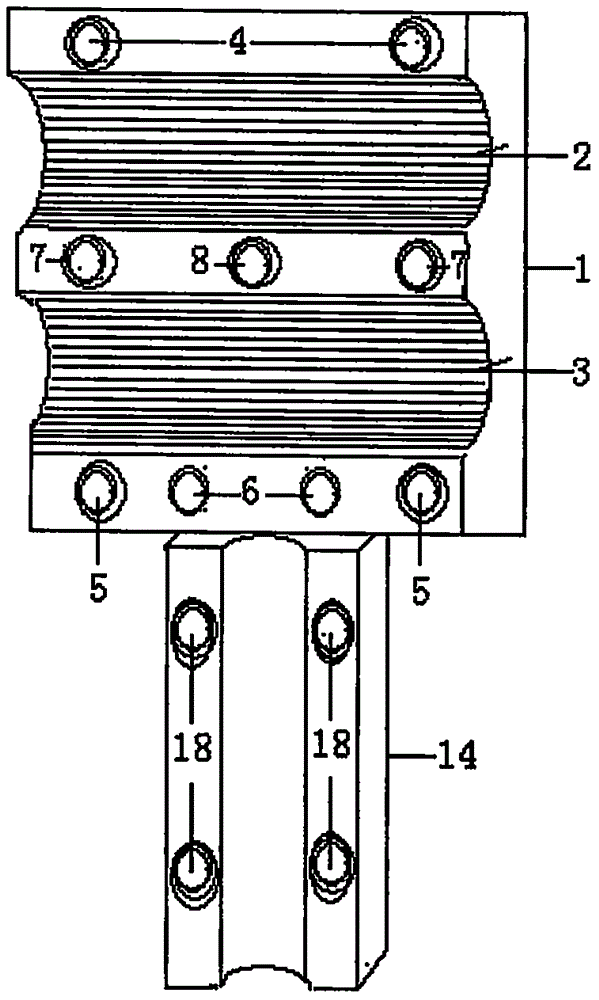

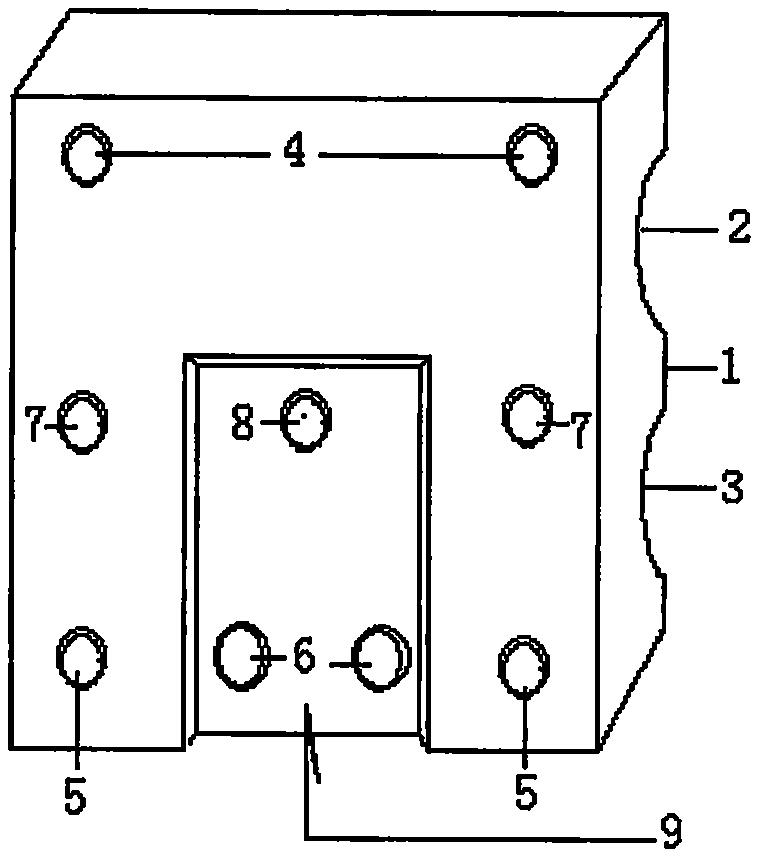

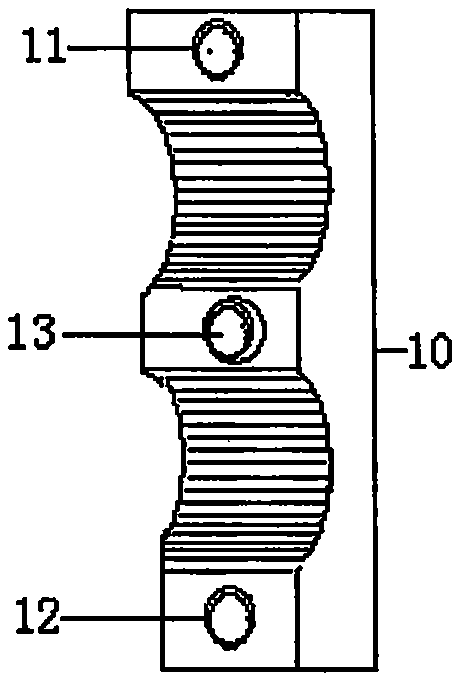

[0023] figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 shows the structure of the present invention, figure 1 The upper and lower ends of the double-groove T-connector body 1 are provided with double-groove crimping grooves 2 and 3, the first full-wire through holes 4 are set on both sides of the upper end of the crimping groove 2, and the second full-wire through-holes are set on both sides of the lower end of the crimping groove 3 5. A third full-wire through-hole 6 is set in the middle of the second full-wire through hole 5, a fourth full-wire through-hole 7 is set on both sides of the middle part of the double-groove T-connector body 1, and a fifth full-wire through-hole 8 is set in the middle. figure 2 A square dimple 9 is set at the bottom of the back of the double-groove T-connector body 1, and the relative positions of the crimping grooves 2 and 3 are set at the front image 3 The double-groove T-connected cover 10, the upper end of the double...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com