Electric connector and manufacturing method thereof

A technology for electrical connectors and manufacturing methods, which is applied in the direction of connection, manufacture of contact box/base, parts of connection devices, etc., can solve the problems of limiting the maximum transmission value of current, the fragile overall structure of the connector, etc., and achieve increased thickness and width effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to facilitate the understanding of the present invention, the following describes the embodiments of the present invention in more detail with reference to the accompanying drawings and specific embodiments.

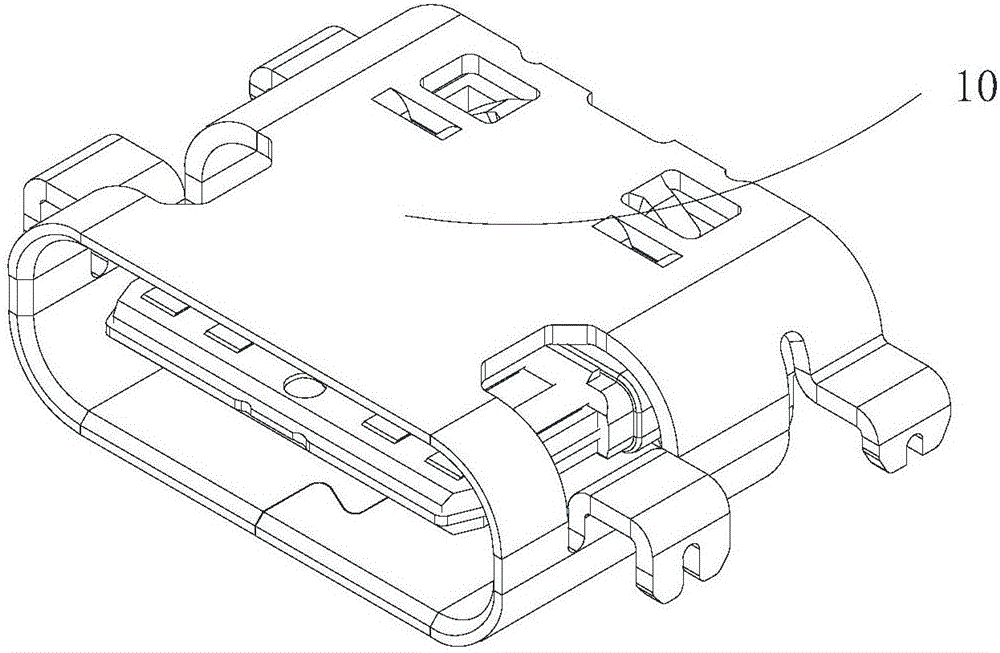

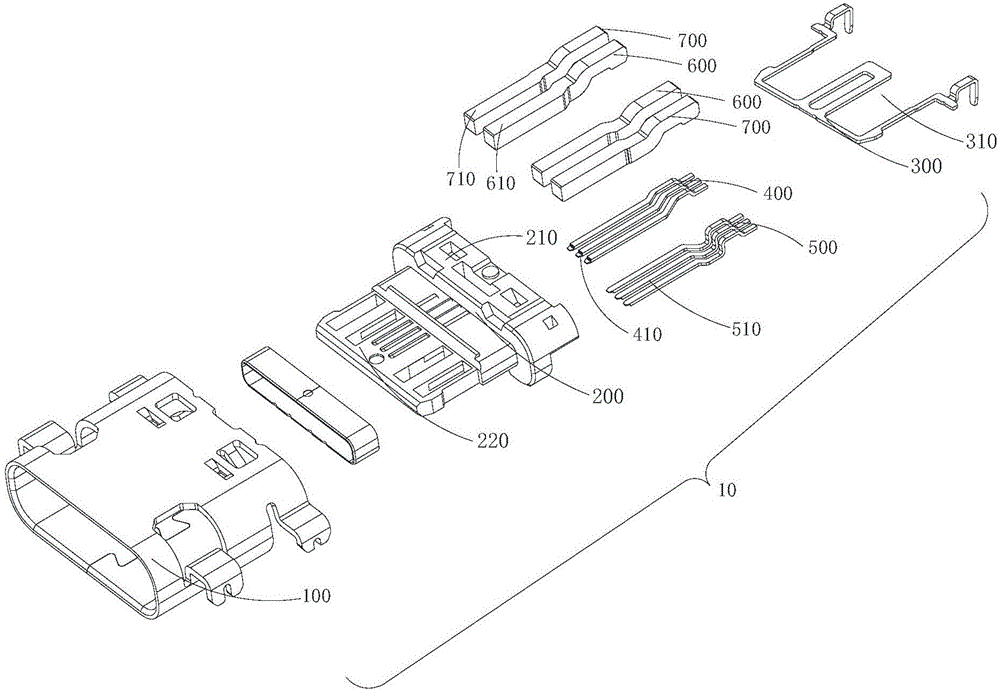

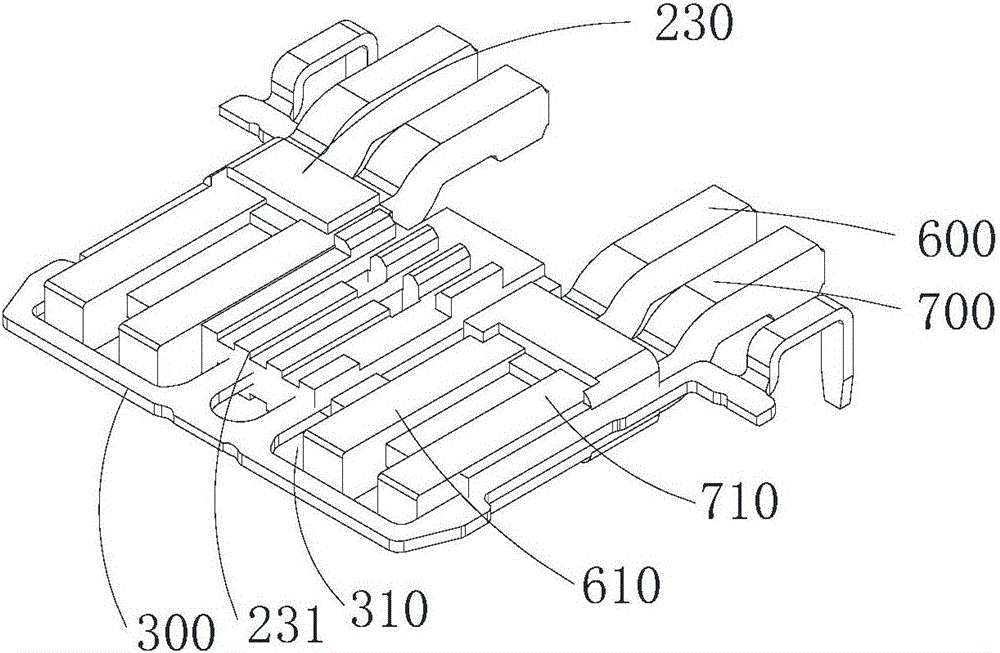

[0026] The embodiment of the present invention discloses an electrical connector, please refer to Figure 1-Figure 4 , An embodiment of the present invention provides an electrical connector 10, figure 1 Shows a perspective view of an electrical connector of an embodiment of the present invention, figure 2 A perspective exploded view of the electrical connector is shown. The connector includes a housing 100, an insulating body 200, a shielding plate 300, a first conductive terminal 400, a second conductive terminal 500, a power terminal 600, and a ground terminal 700.

[0027] The insulating body 200 includes a base 210 and a tongue 220 connected to the base.

[0028] The shield plate 300 is embedded in the tongue plate 210, is located between the first conduct...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com