A modular subway energy feedback device based on series and parallel structures

An energy feedback and modularization technology, which is applied in the direction of output power conversion device, climate change adaptation, irreversible DC power input conversion to AC power output, etc., can solve the problem of not being able to flexibly cover different current levels and meet power requirements flexibly. Level requirements, no redundant operation capabilities, etc., to achieve the effect of ensuring realizability, reducing size, and small amplitude

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

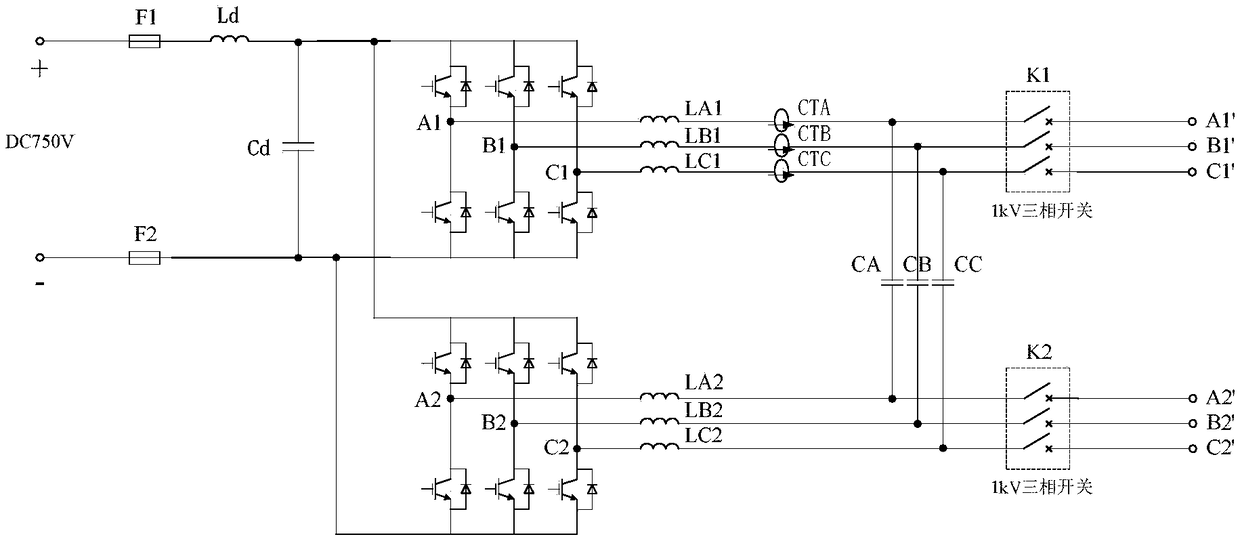

[0033] There is only one DC750V inverter module group in the circuit. At this time, the voltage measured by the DC network is 750V. Inside the inverter module group, a certain number of DC750V inverter modules can be connected in parallel according to the actual current.

Embodiment approach 2

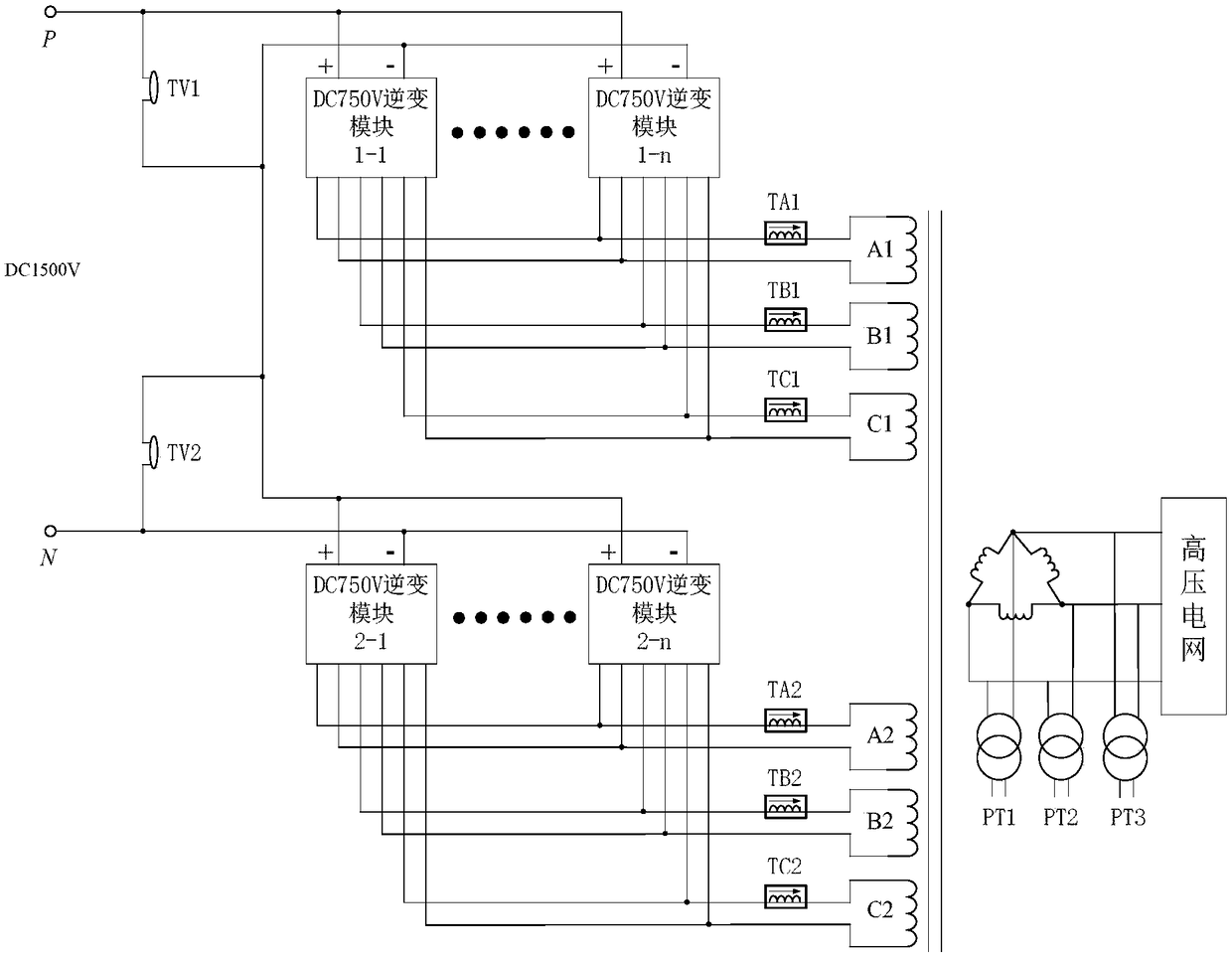

[0035] There are two groups of DC750V inverter modules in the circuit, and the two groups of inverter modules are connected in series. At this time, the shared voltage is 1500V. If one inverter module in each group cannot meet the current requirements, a certain number of inverter modules are connected in parallel according to the magnitude of the current. DC750V inverter module.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com