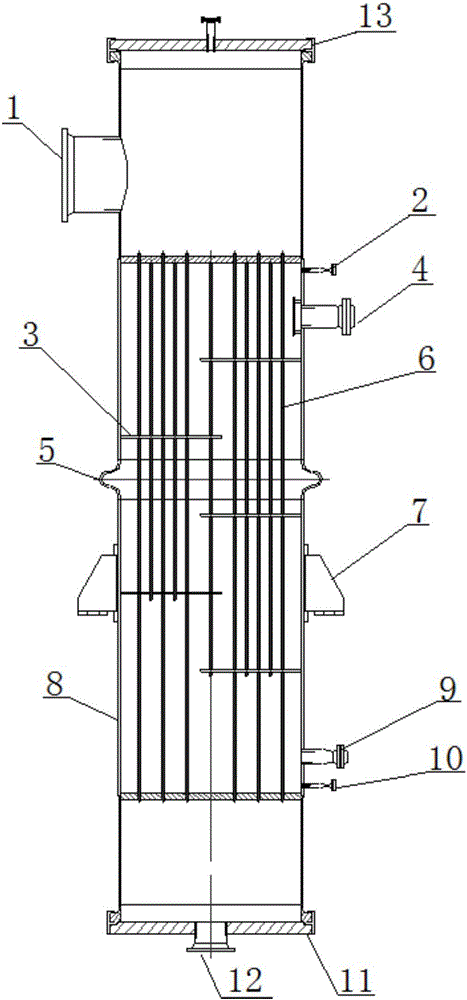

Steam reboiler with expansion joint

A technology of steam reboiler and reboiler, which is applied in the direction of distillation and separation, chemical instruments and methods, fractionation, etc., which can solve the problem of intermingling between tube and shell side media, reducing the service life of equipment, and the tension between tube sheets and heat exchange tubes. cracks and other problems, to achieve the effect of prolonging the service life, reducing the occurrence of internal leakage and reducing the effect of stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the drawings and embodiments.

[0021] Reference figure 1 As shown, the steam reboiler with expansion joints in an embodiment provided by the present invention includes a reboiler shell and a heat exchange tube bundle 6. The upper and lower ends of the reboiler shell 8 are both provided with heads. The heat tube bundle 6 is arranged in the reboiler shell 8. The reboiler shell 8 is sequentially provided with a pipe-side discharge port, a steam inlet 4, a steam outlet 9 and a pipe-side feed port from top to bottom. Port 1 and tube side feed port 12 are respectively connected to the heat exchange tube bundle 6, the space formed inside the reboiler shell 8 and outside of the heat exchange tube bundle 6 is the shell side space, and the steam inlet 4 and the steam outlet 9 are connected to the shell side space , The reboiler shell 8 includes a multi-stage unit shell, and the unit shells are connected by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com