Major-diameter prestressed concrete pipe pile of glass steel pipe die and preparation method thereof

A technology of concrete pipe piles and glass steel pipes, which is applied to sheet pile walls, manufacturing tools, ceramic molding machines, etc., can solve the problems of long-distance transportation of super-long pipe piles and single mold specifications, so as to reduce the transportation workload and improve penetration The effect of high capacity and arbitrary pile length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

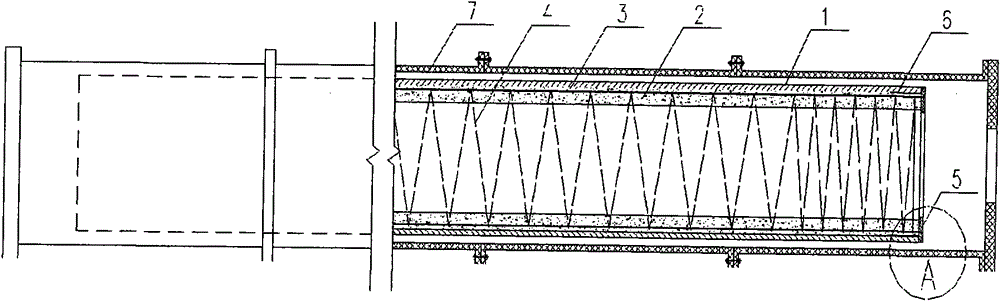

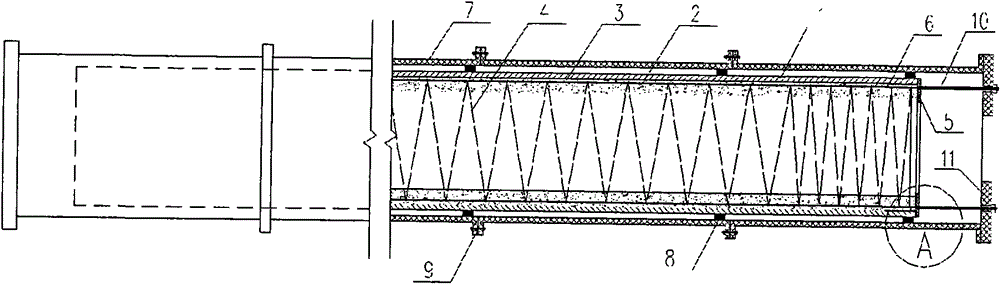

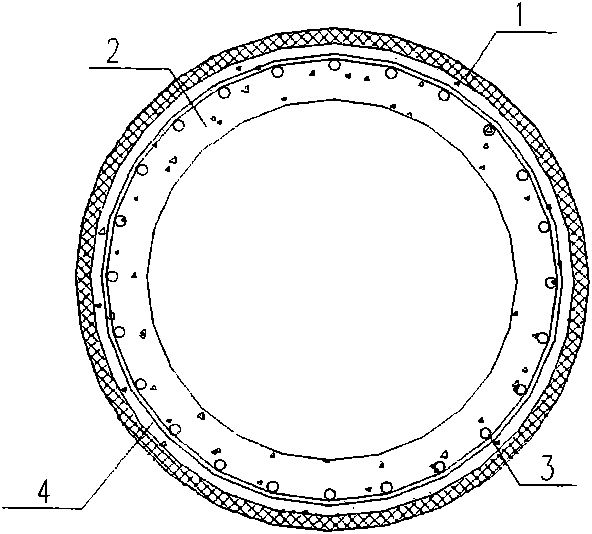

[0026]A large-diameter prestressed concrete pipe pile with a glass steel pipe mold, which is characterized in that it includes: a glass steel pipe outer mold 1, a concrete lining 2, a steel end plate 5 and a steel plate hoop 6, and the concrete lining 2 is arranged outside the glass steel pipe Inside the formwork 1, a reinforced skeleton composed of prestressed longitudinal reinforcement 3 and spiral stirrup 4 is arranged in the concrete lining 2, steel end plates 5 are arranged at both ends of the pile, and the steel plate hoops 6 are arranged on the steel end plates 5 And it is located between the glass steel pipe outer mold 1 and the concrete inner lining 2 , and the prestressed longitudinal reinforcement 3 is anchored in the anchor hole of the steel end plate 5 .

[0027] The steel casing working member 7 temporarily wraps the glass steel pipe outer mold 1, and the gap between the two is wedged tightly with a wooden triangle block. The steel casing working member 7 bears th...

Embodiment 2

[0030] A method for preparing a large-diameter prestressed concrete pipe pile with a glass steel pipe mold, the main steps are as follows:

[0031] Step 1: According to the design length of the pipe pile, the outer mold 1 of the glass steel pipe and the prestressed longitudinal reinforcement 3 are blanked. The ribs 4 are welded to form the reinforcement skeleton of the pile body. The reinforcement skeleton is positioned and placed in the outer mold 1 of the glass steel pipe, and steel end plates 5 and steel plate hoops 6 are installed at both ends. Pour into the glass steel pipe outer mold 1 pipe;

[0032] Step 2: On the periphery of the glass steel pipe outer mold 1, assemble and assemble multi-segment steel casing working members 7, each steel casing working member 7 has a segment length of 2m to 3m, connected by a flange 9, and the glass steel pipe outer mold 1 and the gap between the steel casing temporary workpiece 7, use a wooden wedge block 8 to wedge tightly;

[0033...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com