Anchoring structure and manufacturing method of stay cable and bridge tower

A manufacturing method and technology for stay cables, which are used in bridges, bridge construction, bridge parts, etc., can solve the problems of narrowing the vertical spacing of stay cables, large amount of steel used for anchoring in steel anchor boxes, and easy cracking of concrete corbels. , to achieve the effect of reducing welding space requirements, reducing the number of hoisting, good engineering economy and construction convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] This embodiment provides a stay cable and bridge tower anchorage structure;

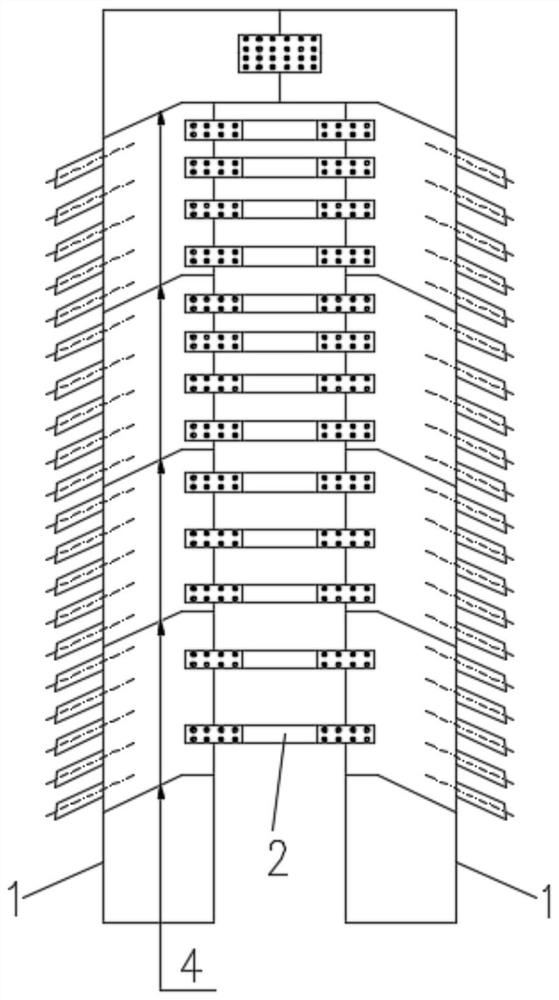

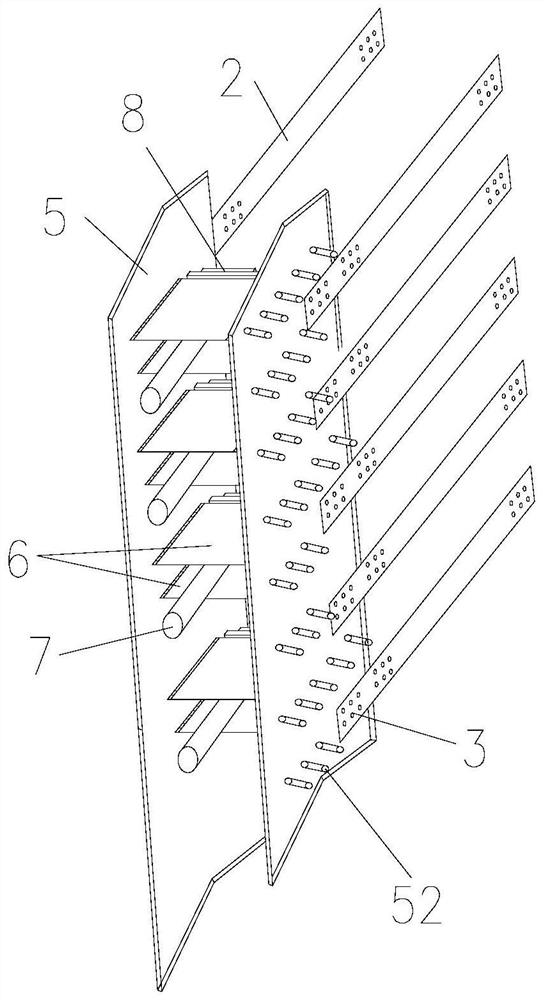

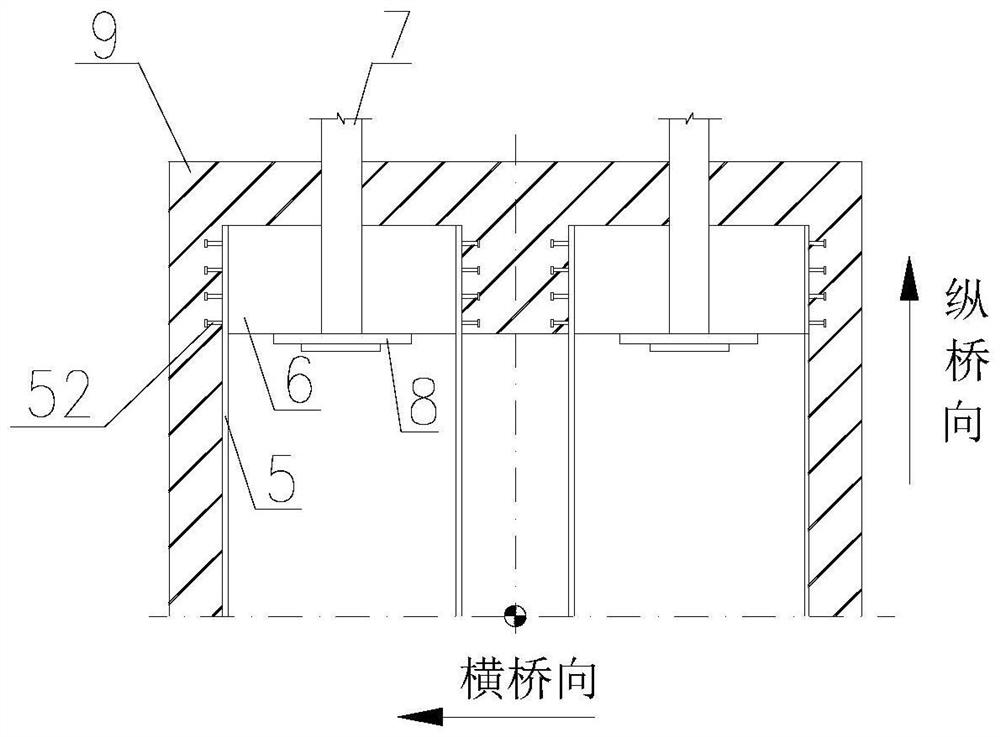

[0039] like Figure 1-3 As shown, the stay cable and bridge tower anchorage structure in this embodiment includes anchorage structures 1 symmetrically arranged on both sides of the bridge tower and several connecting plates 2 connecting the two anchorage structures 1, each of the anchorage structures 1 Along the axial direction of the bridge tower, the anchor segment dividing line 4 is divided into several anchor segments, and the inclined segment consistent with the direction of the stay cable sleeve 7 and the straight segment consistent with the direction of the connecting plate 2 are used between each anchor segment. Each anchor segment includes two opposite anchor side plates 5 and a number of shear plates 6 located between the two anchor side plates 5 and arranged along the direction of the stay cable sleeve 7 , and several shear plates 6 are arranged at intervals along the axial directi...

Embodiment 2

[0045] This embodiment provides a method for manufacturing the anchorage structure of stay cables and bridge towers as in Embodiment 1;

[0046] like Figure 5 As shown, the manufacturing method of the stay cable and bridge tower anchorage structure in the present embodiment comprises the following steps:

[0047] Step A, welding the stay cable sleeve 7 and the anchor backing plate 8 together, and welding with a pair of shear plates 6;

[0048] Step B, welding the shear plate 6 with the stay cable sleeve 7 and the anchor backing plate 8 on the anchor side plate 5 without holes;

[0049] Step C, repeat steps A and B to weld the remaining shear plate 6 and the anchor side plate 5 welds;

[0050] Step D, install the anchoring side plate 5 with the hole 51 and the shear plate 6 on the anchoring segment in pairs of holes, and weld the connection weld between the shearing plate and the anchoring side plate on the outside of the opening anchoring side plate to form an anchor Segme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com