Automatic assembly equipment for LED panel lamp

An LED panel light and automatic assembly technology, which is applied in the direction of metal processing equipment, assembly machines, manufacturing tools, etc., can solve the problems of low production efficiency, uneven assembly quality, and large manual labor of LED panel lights, so as to improve production. Efficiency and assembly quality, precise movement position, effect of volume and footprint reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in combination with specific embodiments and accompanying drawings.

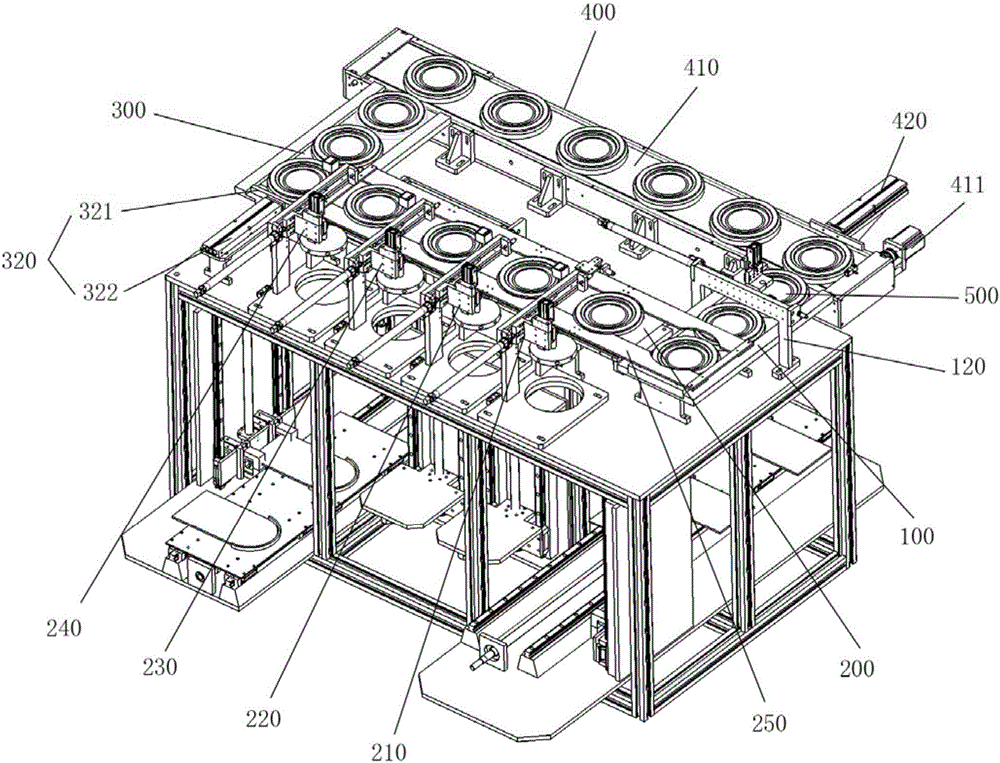

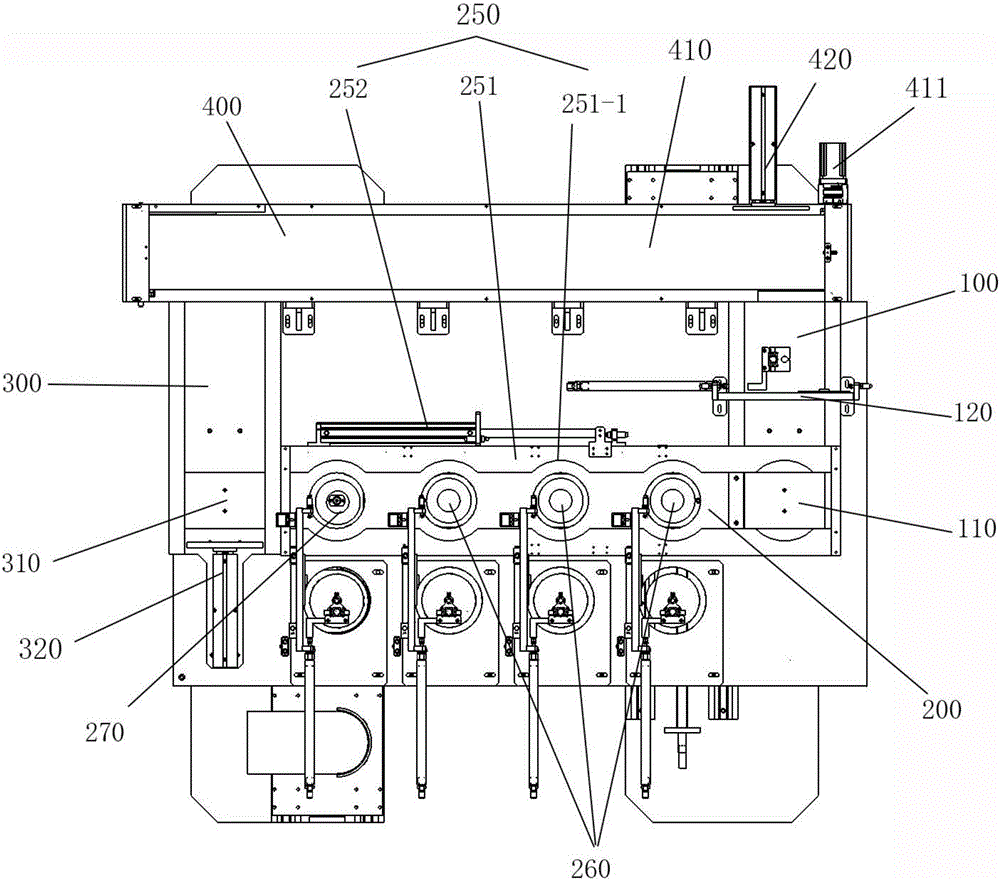

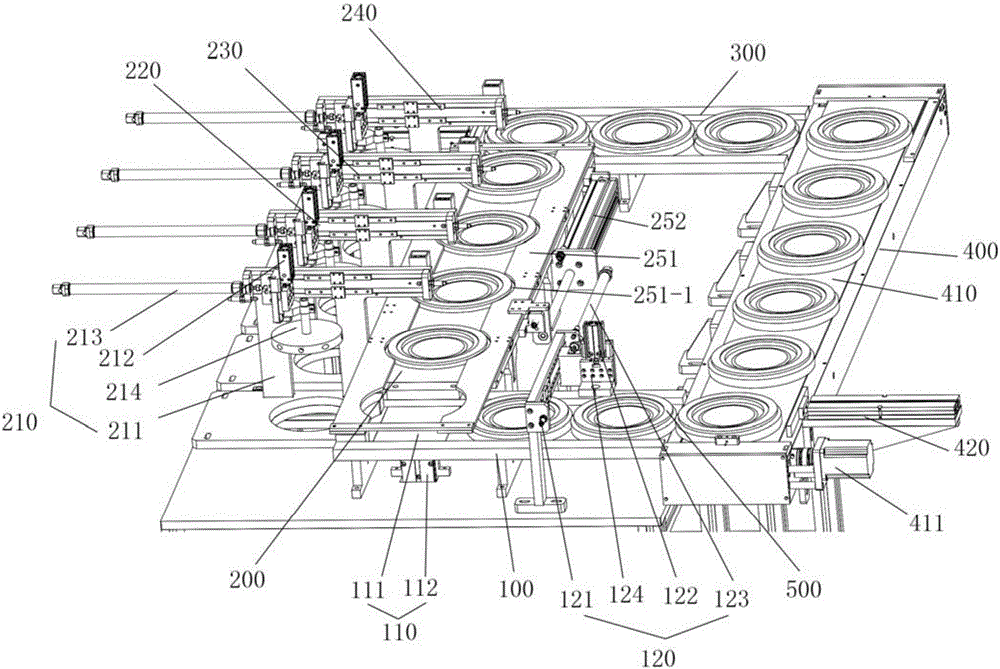

[0026] Such as Figure 1-3 As shown, an automatic assembly equipment for LED panel lights includes a workbench, and the workbench is arranged in a rectangular order with an unloading and loading track 100, an operation assembly track 200, a carrier turnover track 300, and a carrier return track 400. Each track A carrier 500 for carrying the base of the panel light is placed on each of them, wherein:

[0027] The carrier 500 is a circular carrier, and the specifications and sizes of each carrier 500 are the same, and the carrier 500 is provided with a place for placing a panel light base;

[0028] The unloading and loading track 100, the carrier turnover track 300 and the carrier return track 400 are at the same level, and the operation assembly track 200 is higher than the unloading and loading track 100, the carrier turnover track 300 and the car...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com