Preheating type manual assembly head for bearing

A technology of pre-heating and assembling head, applied in the field of bearings, can solve the problems of difficult to grasp the bearing force and frequency, easy deflection of the bearing outer ring, low installation accuracy, etc., to reduce labor intensity, stable installation process, improve The effect of installation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

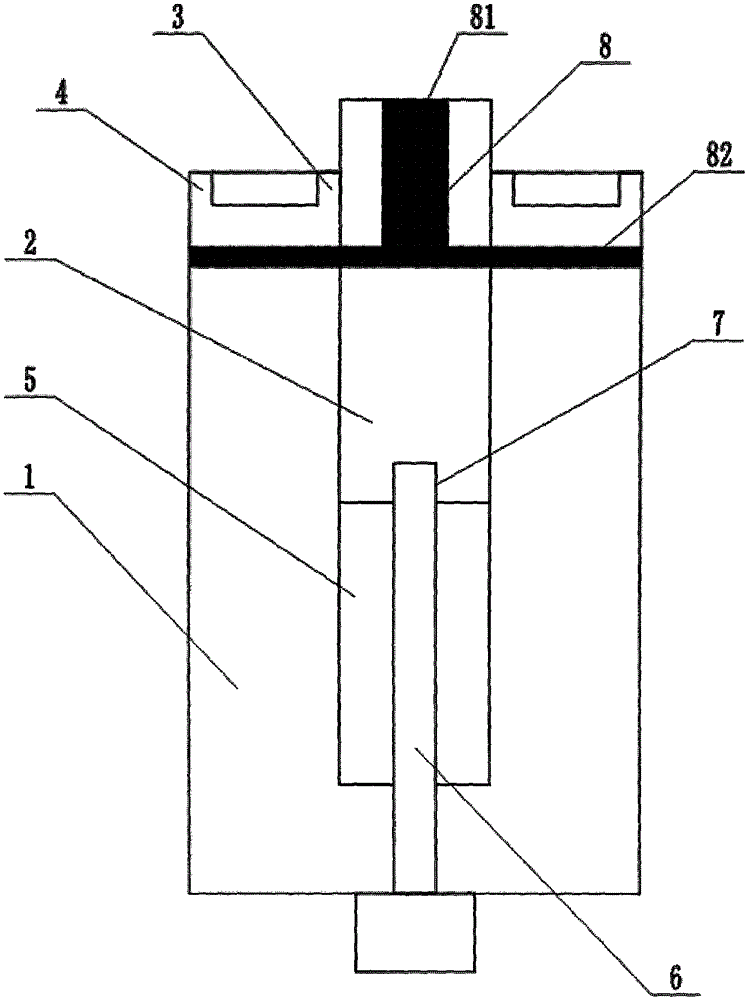

[0010] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0011] Such as figure 1 As shown, the preheated manual assembly head of the bearing in this embodiment includes a main mounting column 1 and a preliminary installation jacking column 2 installed at the front end of the main mounting column 1. The front end of the main mounting column 1 has a mounting groove 5 for installation Spiral installation in the slot 5 preliminarily installs the top column 2; the rear end surface of the main installation column 1 has a through hole communicating with the installation slot 5, and an adjustment rod 6 is inserted in the through hole, and the end of the adjustment rod 6 is inserted in the preliminary installation The end surface of the top column 2 fits in the groove 7; the front end surface of the main installation column 1 also has an outwardly protruding bearing inner ring abutment ring 3 and a bearing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com