Ultra-high-speed injection molding machine

An injection molding machine, ultra-high-speed technology, applied in the field of ultra-high-speed injection molding machines, can solve the problems of slow injection speed, difficult to process precision products and thin products, long injection cycle, etc. The effect of speed increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

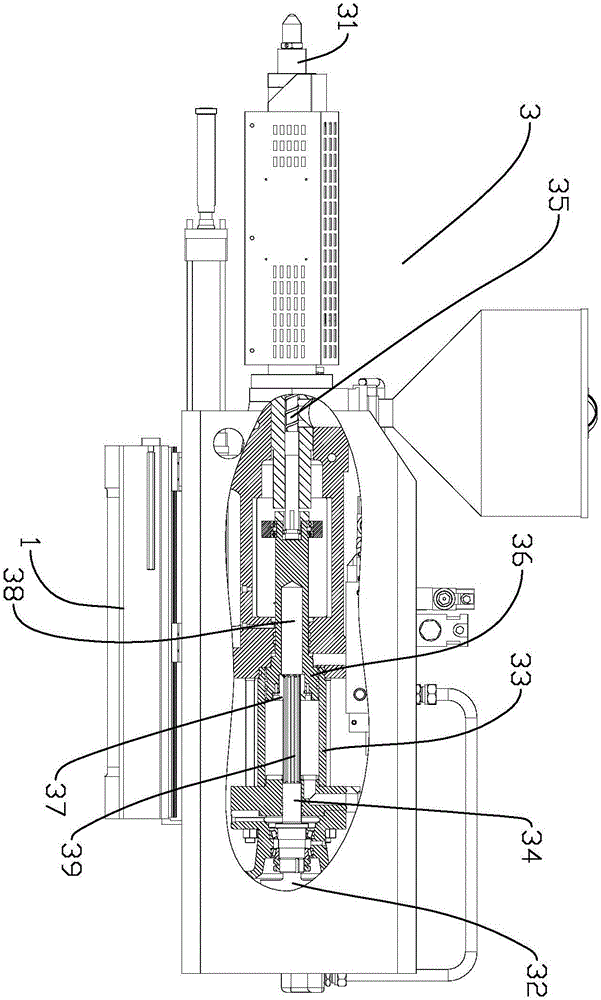

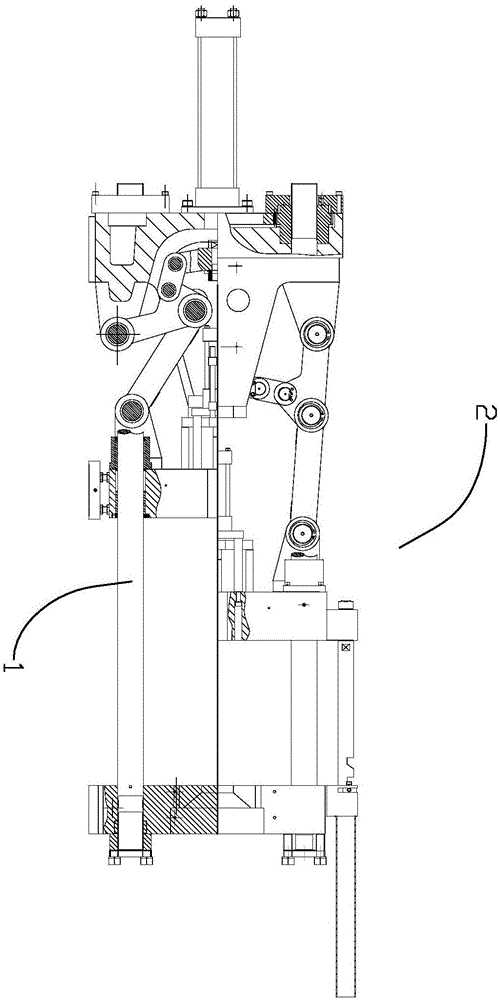

[0022] refer to Figure 1 ~ Figure 2 , the present invention is an ultra-high-speed injection molding machine, comprising: a frame 1; a mold clamping mechanism 2, which is arranged on the frame 1, and is used to control mold clamping and mold locking; a melt glue injection mechanism 3, which is arranged on the frame 1, used to inject glue into the mold; the control mechanism includes the first hydraulic pump, the second hydraulic pump and the confluence valve, the first hydraulic pump provides power for the clamping mechanism 2 through the first pipeline assembly, and the second hydraulic pump passes through The second pipeline component provides power for the melt glue injection mechanism, the confluence valve is connected with the first pipeline component and the second pipeline component, and can control the connection or isolation between the first pipeline component and the second pipeline component; the cooling device, Set in the mold to accelerate the cooling rate of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com