Marking and punching all-in-one machine for packaging film

A packaging film, integrated machine technology, applied in packaging, transportation and packaging, printing machines, etc., can solve the problems of wasting manpower and material resources, increasing production time, and transferring multiple packaging film links, so as to protect from damage and improve work efficiency. , the effect of avoiding unnecessary operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

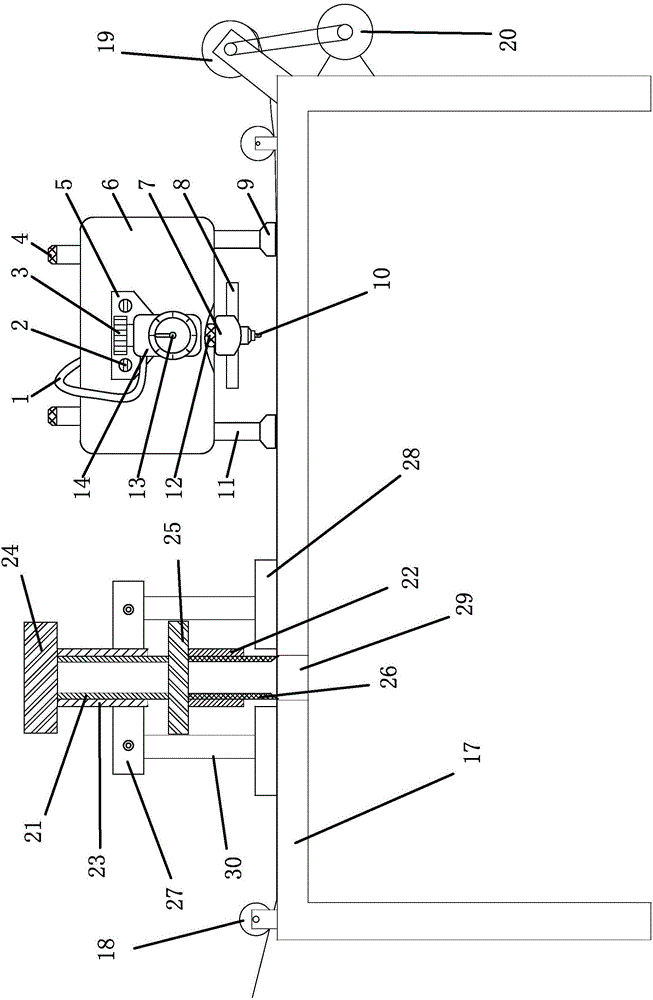

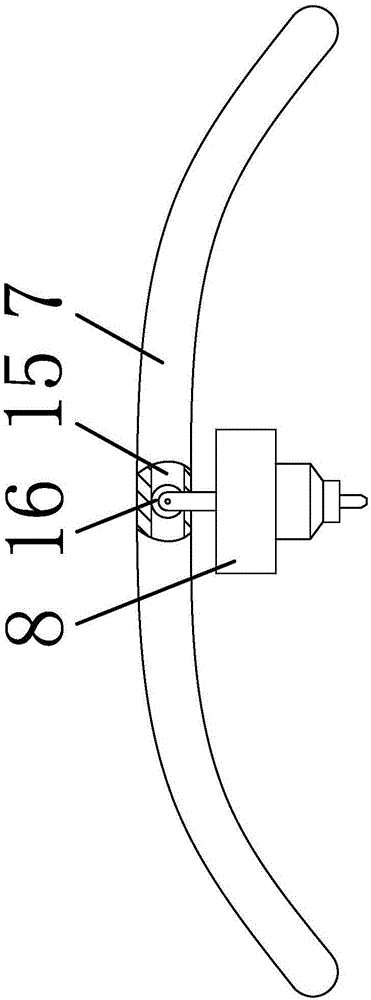

[0019] Such as figure 1 , figure 2 As shown, the marking and punching all-in-one machine of the packaging film includes a horizontal table 17, a punching mechanism and a marking mechanism. One end of the horizontal table 17 is rotatably connected to an unwinding roller 18, and the other end is rotatably connected to a winding roller 19. The winding roller 19 is driven by a motor 20 fixed on the side of the horizontal table 17 , and the punching mechanism and the marking mechanism are arranged on the horizontal table 17 between the unwinding roller 18 and the winding roller 19 .

[0020] The punching mechanism comprises a hollow rod one 21, a hollow rod two 22 and a support sleeve 23. The top of the support sleeve 23 is fixedly equipped with a hydraulic cylinder one 24, and the hollow rod one 21 is fixedly installed under the hydraulic cylinder one 24. The end face, the lower end of the hollow rod one 21 is fixedly connected with the hydraulic cylinder two 25, the lower end o...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap