Method for producing nickel oxide from nickel-plating wastewater

A technology of nickel oxide and nickel plating, applied in chemical instruments and methods, preparation of nickel oxide/nickel hydroxide, nickel compounds, etc., can solve problems that have not been applied in industry, achieve increased added value, reduce costs, and increase nickel The effect of the value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

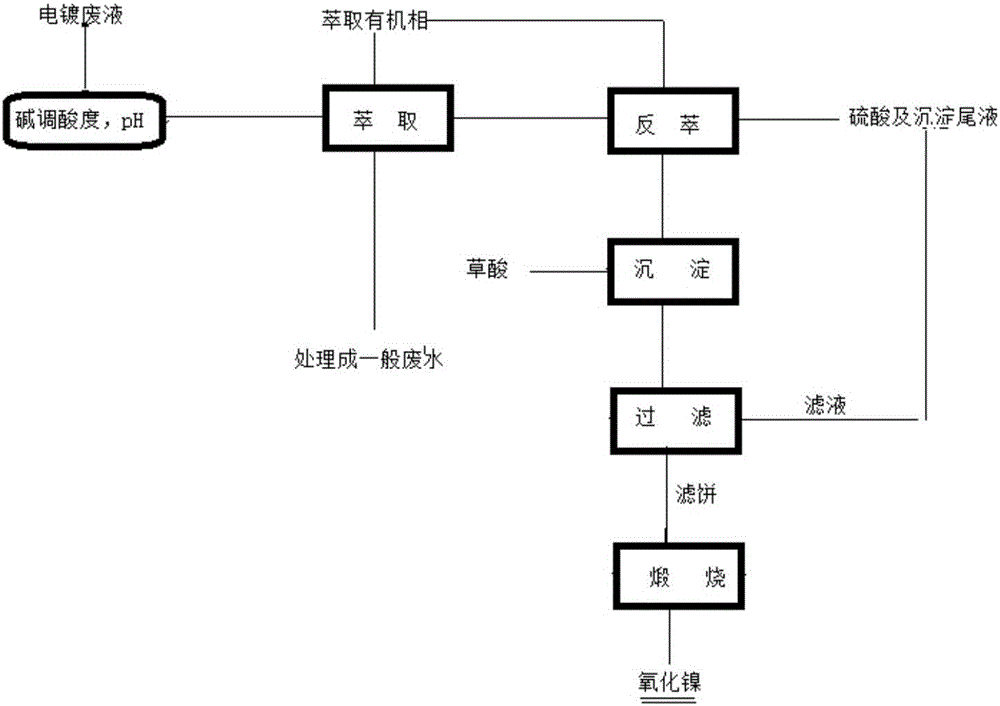

[0023] Such as figure 1 Shown, the present invention mainly comprises four aspects technical contents:

[0024] 1) Use the extraction process to extract nickel plating waste liquid to obtain nickel-extracted organic matter; the organic matter used in the present invention is a phosphate compound extractant, and the ratio of the compound organic matter to sulfonated kerosene is 1:1-2, or use trioctyl Methyl ammonium chloride is used as an extractant, and the total organic matter: nickel plating wastewater is extracted for 3-5 minutes under the condition of 1:1, and the extracted organic matter is obtained after phase separation.

[0025] 2) Sulfuric acid and precipitation tail liquid are carried out back-extraction; the extracted organic matter is back-extracted with sulfuric acid, the concentration of sulfuric acid is 1-3mol / L, and the organic ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap