A Drilling Tool Using Vortex-Induced Vibration to Realize Axial Shock

An axial impact and drilling tool technology, applied in the direction of drilling with vibration, can solve the problems of high pressure loss and limited service life, and achieve the effects of low tool pressure loss, prolonging service life and shortening drilling cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

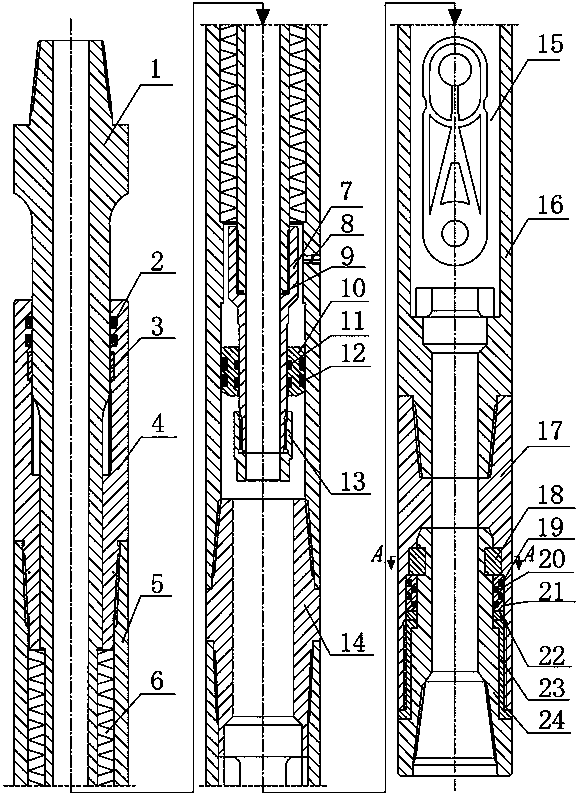

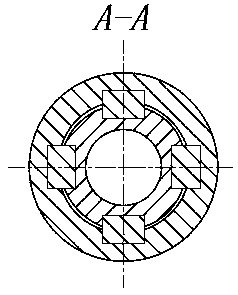

[0016] The present invention will be further described below in conjunction with accompanying drawing:

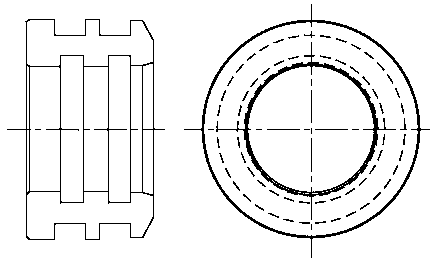

[0017] See attached figure 1 , a drilling tool that uses vortex-induced vibration to achieve axial impact. The axial impactor is fixedly installed on the upper part of the drill bit through a threaded connection. The axial impactor includes a shock absorber, a vortex-induced oscillator, and an impact joint assembly. The front end of the vortex-induced oscillator is connected to the impact joint assembly, and the rear end is connected to the shock absorber; the shock absorber includes a spline shaft 1, a sealing ring a2, a wear-resistant ring 3, a spline shell 4, an upper shell 5, and a disc spring 6 , anti-drop short joint 7, oil plug 8, rectangular sealing ring a9, retaining ring 10, sealing ring b11, sealing ring c12, anti-dropping cap 13, and then install the sealing ring a2 and wear-resistant ring 3 into the spline housing 4 in sequence On the inner circumference of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com