Oil stop device, rotor assembly, compressor and air conditioning equipment

A technology of rotors and components, applied in the field of compressors, can solve problems such as fixed flow area and inability to adapt to different operating conditions of compressors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below with reference to the drawings and specific embodiments, but it is not intended to limit the present invention.

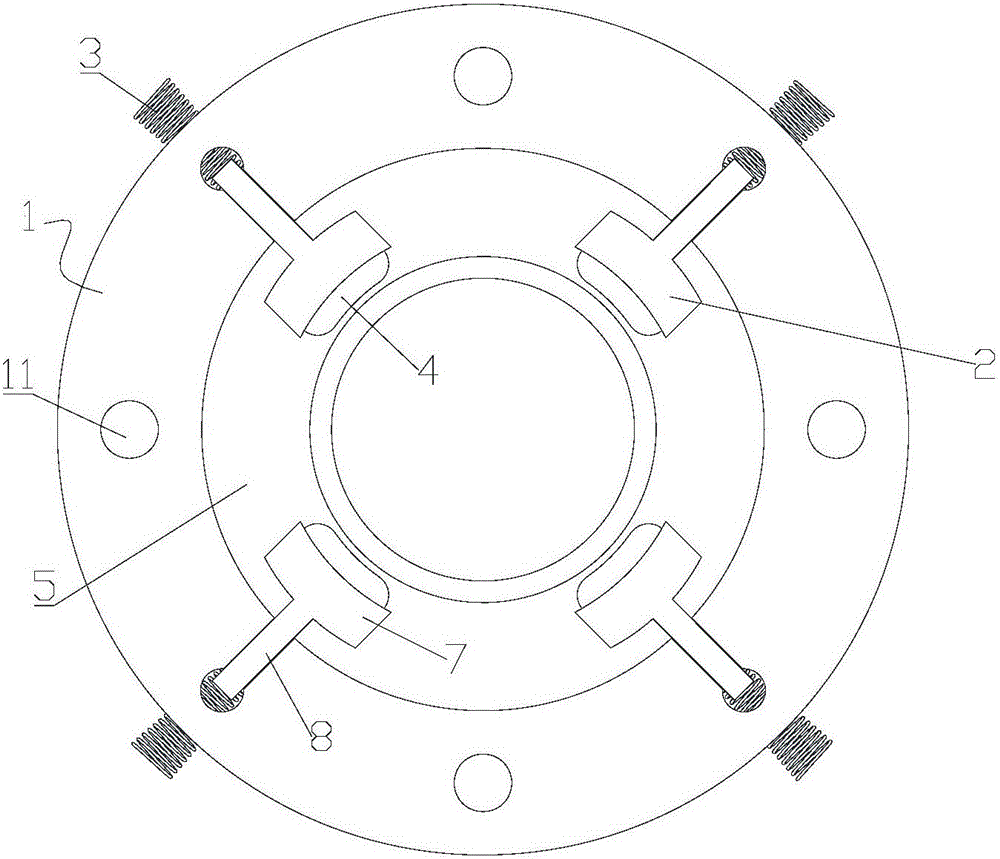

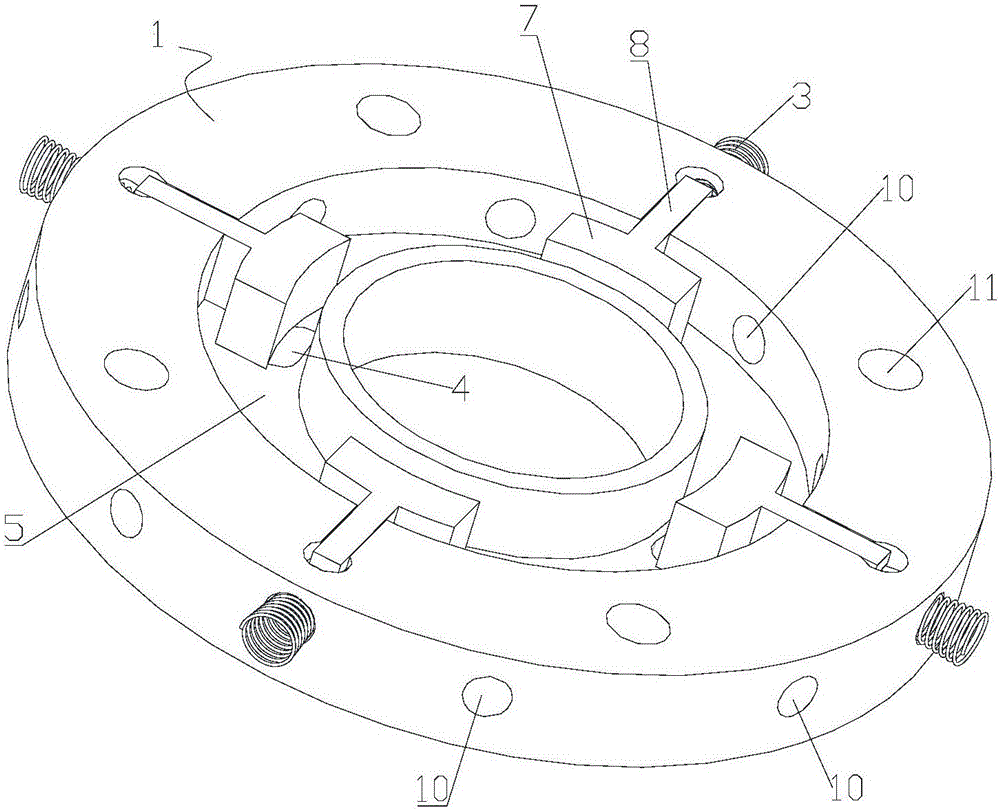

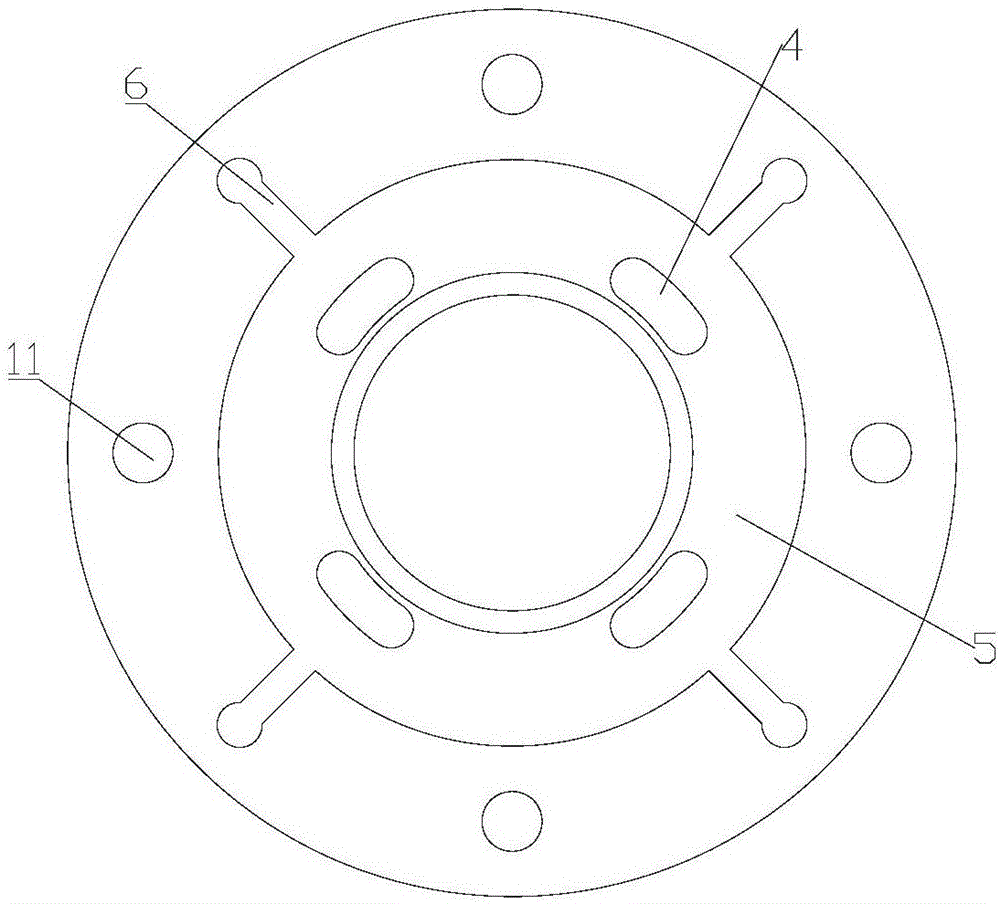

[0036] Please refer to Figure 1 to Figure 8 , The oil blocking device of the present invention can be used in a rotor assembly, which includes a body 1, a slider 2, and an elastic element 3. For example, the body 1 has a cylindrical pie-shaped structure, and the elastic element 3 can provide elastic force to balance the centrifugal force generated by the slider 2 when the rotor assembly rotates.

[0037] Among them, the slider 2 is movably arranged on the body 1 and can move along the radial direction of the body 1. The body 1 has one or more air inlets 4 which are arranged on the movement path of the slider 2. The elastic element 3 is installed on the body 1. When the oil blocking device in the present invention is in a static state, the elastic element 3 provides a force to the slider 2 to drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com