burner for stove

A technology for burners and stoves, applied to burners, gas fuel burners, combustion types, etc., can solve the problems of spark plug damage, uneconomical, insufficient restriction of ignition holes, etc., and achieve the effect of improving fire transmission.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

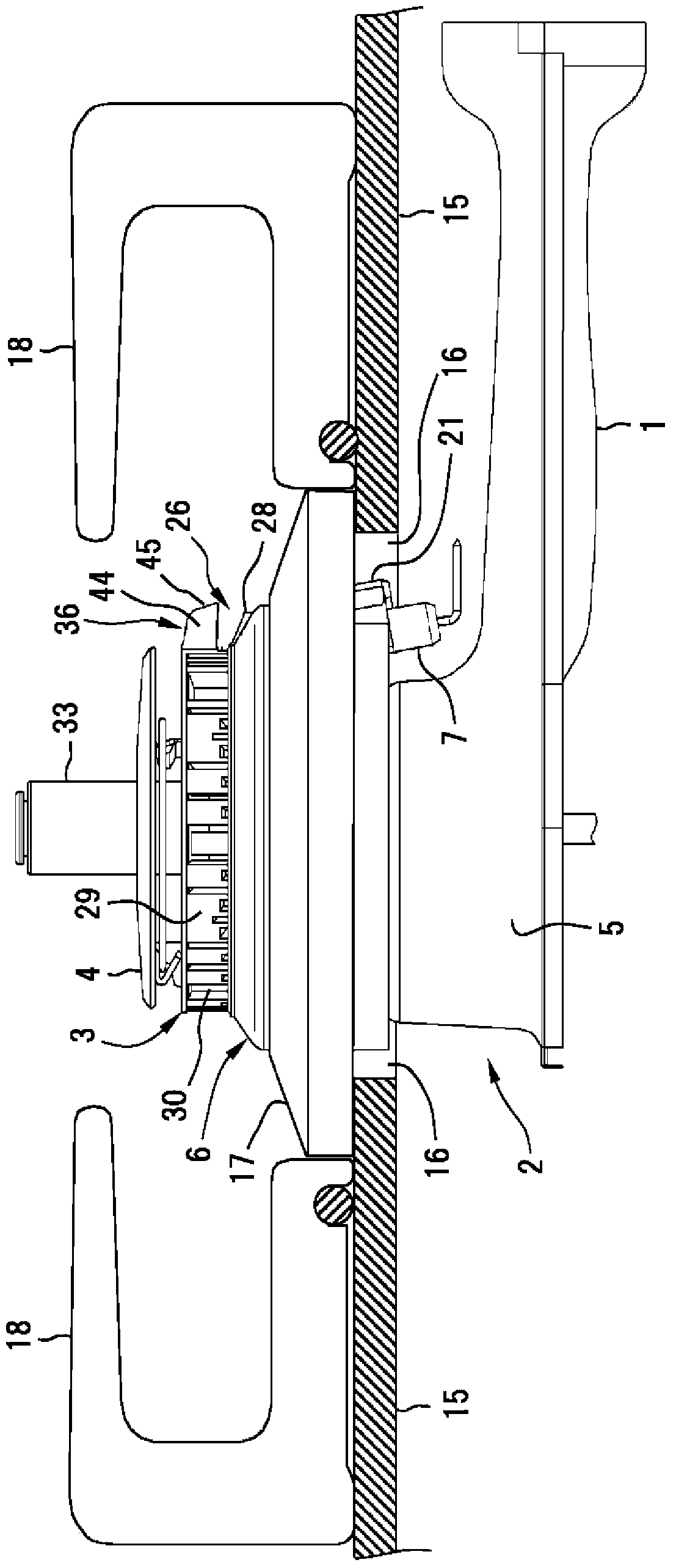

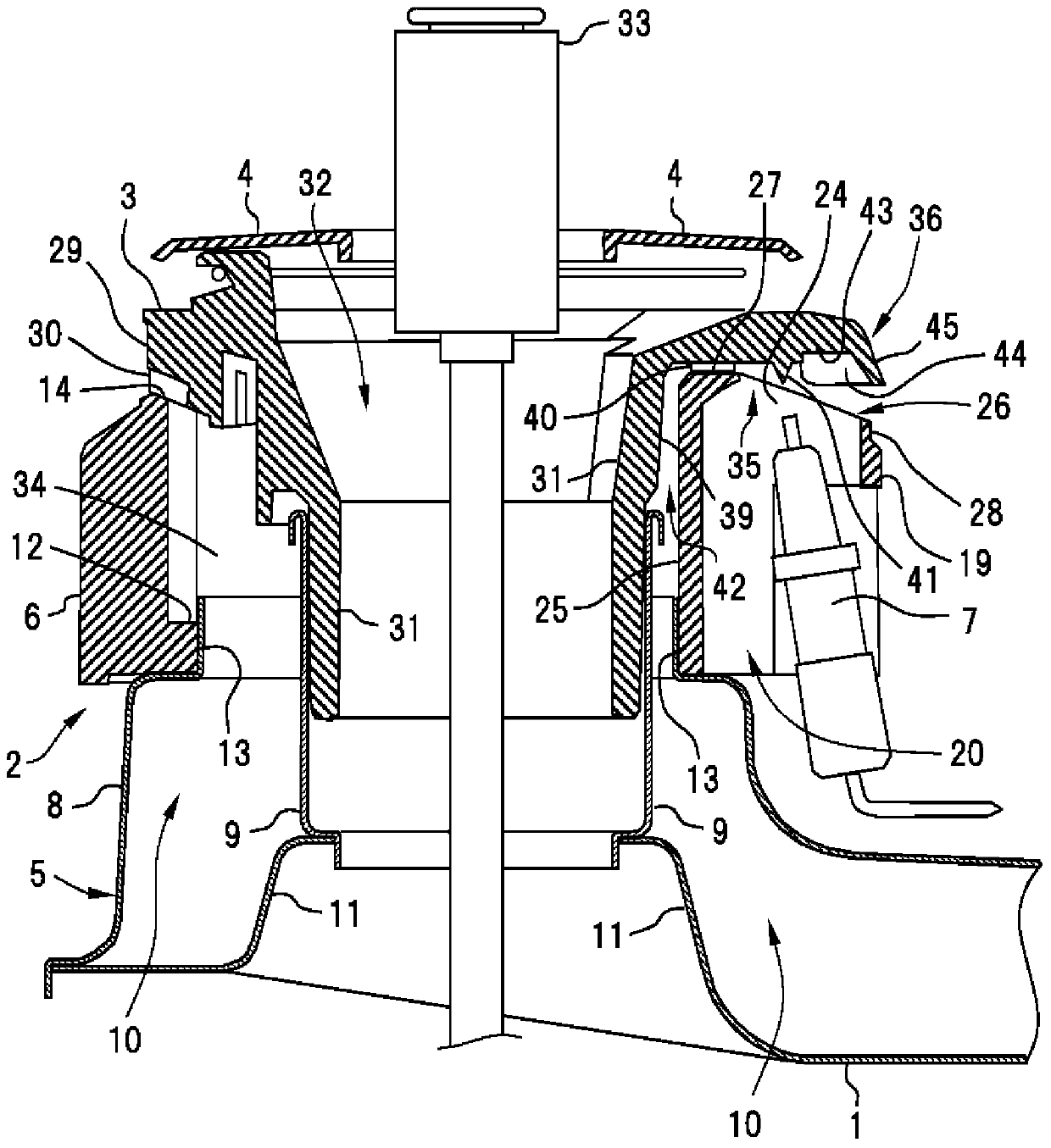

[0054] An embodiment of the present invention will be described with reference to the drawings. Such as figure 1 As shown, the burner for a stove of this embodiment includes a mixing tube 1 , a burner body 2 , a burner head 3 and a burner cover 4 .

[0055] A mixture of gas and primary air is generated in the mixing tube 1 by introducing gas and primary air sprayed from a gas nozzle not shown.

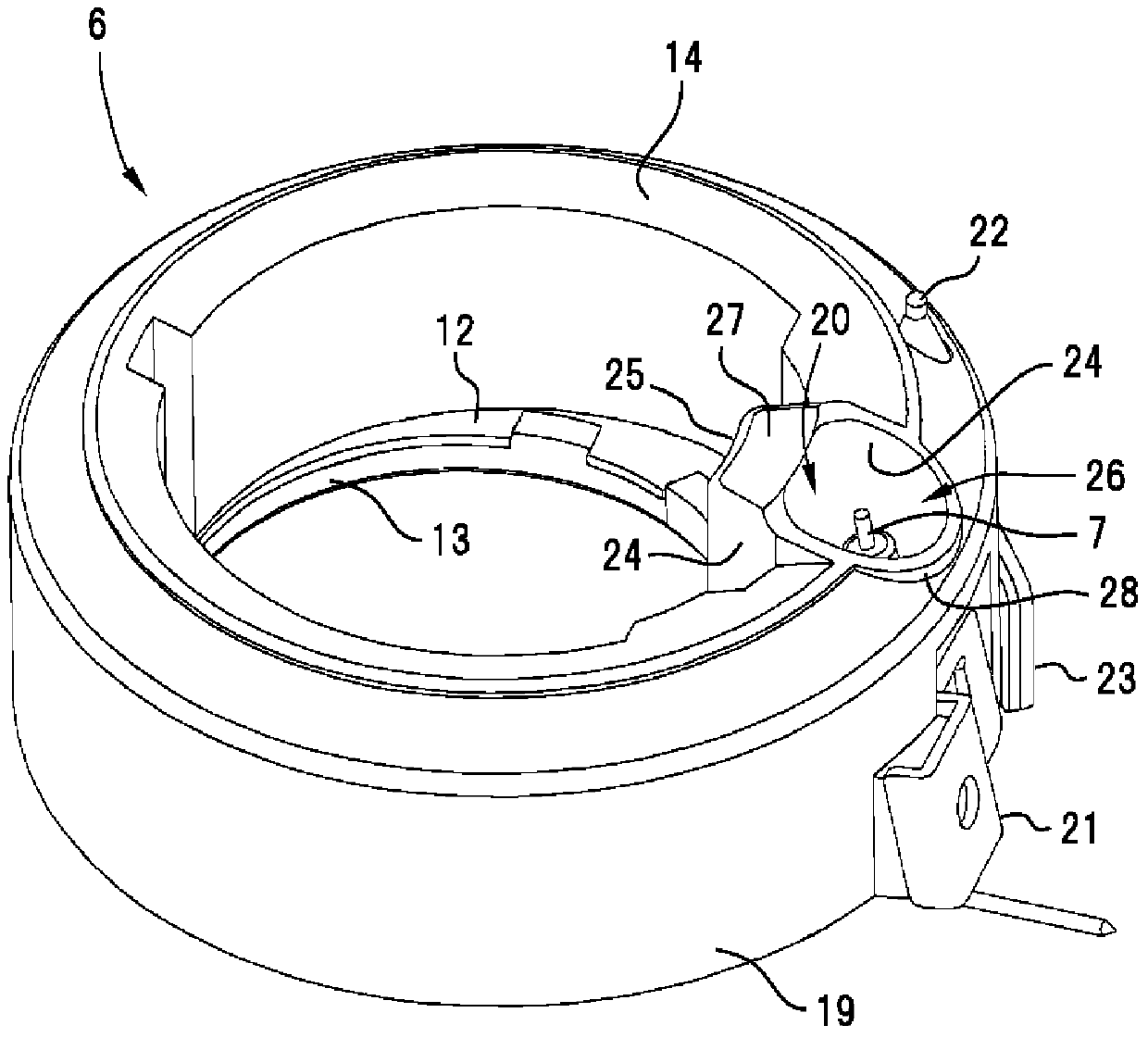

[0056] Such as figure 2 As shown, a burner body 2 is connected to the downstream end of the mixing tube 1 . The burner body 2 includes a base portion 5 formed of a metal plate and a spacer 6 formed by die casting. A spark plug 7 is arranged inside the spacer 6 .

[0057] The base portion 5 of the burner body 2 includes an outer cylinder 8 and an inner cylinder 9 provided inside the outer cylinder 8 . An annular space formed between the outer cylinder 8 and the inner cylinder 9 constitutes a mixed gas passage 10 communicating with the mixing tube 1 .

[0058] Such as figure 2 As ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com