Exhaust gas purification apparatus for internal combustion engine

一种排气净化装置、内燃机的技术,应用在排气装置、排气处理装置的电控、排气处理装置的诊断装置等方向,能够解决难净化等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

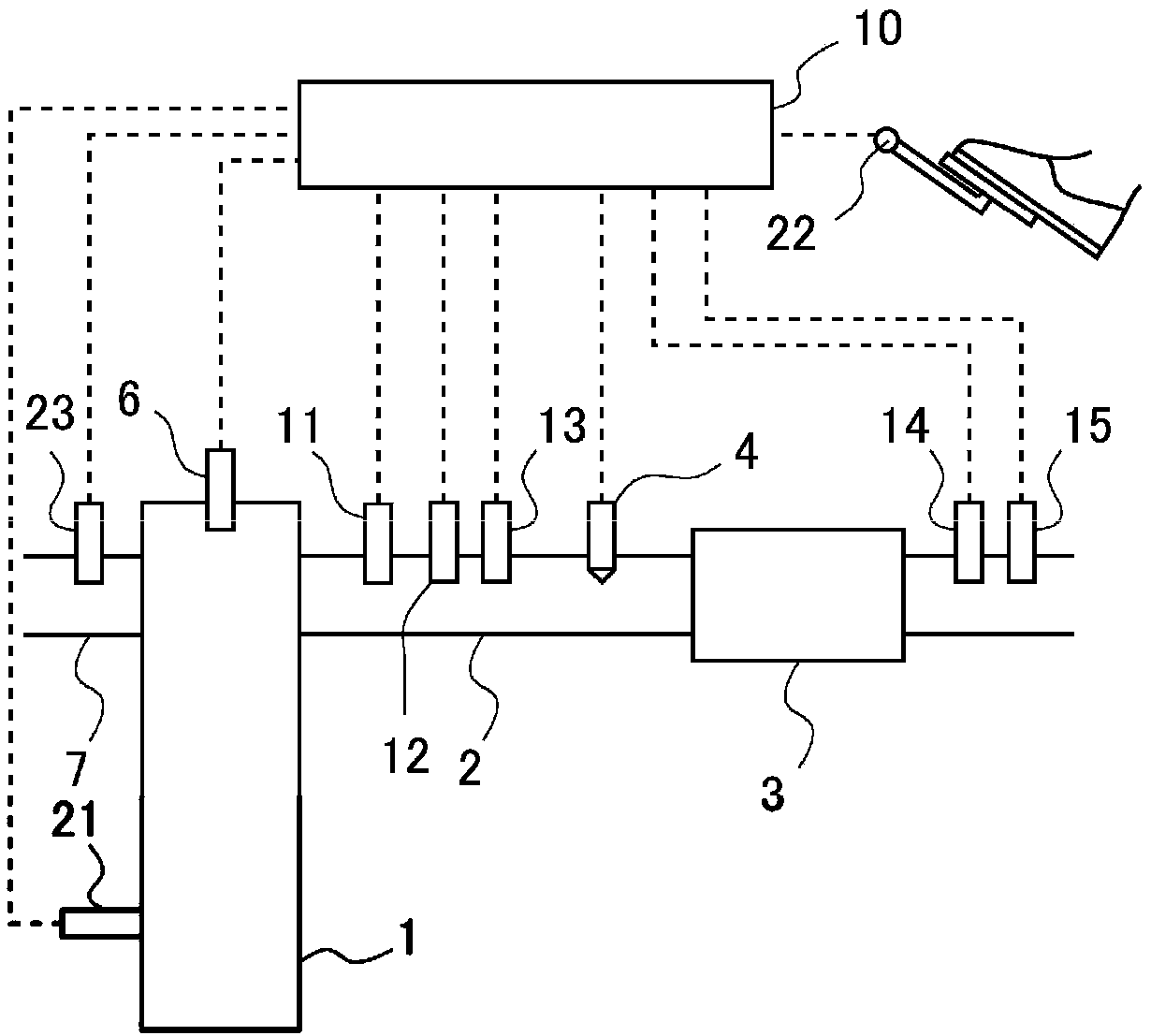

[0051] figure 1It is a figure which shows the schematic structure of the internal combustion engine 1 concerning this Example, its intake system, and an exhaust system. The internal combustion engine 1 is a diesel engine for driving a vehicle. However, the internal combustion engine 1 may also be a gasoline engine. An exhaust passage 2 is connected to the internal combustion engine 1 . A selective reduction NOx catalyst 3 (hereinafter referred to as "NOx catalyst 3") that selectively reduces NOx in exhaust gas using ammonia as a reducing agent is provided in the exhaust passage 2 .

[0052] An addition valve 4 for adding urea water, which is a precursor of ammonia, to the exhaust gas is provided in the exhaust passage 2 upstream of the NOx catalyst 3 . The urea water added through the addition valve 4 is hydrolyzed into ammonia, which is adsorbed on the NOx catalyst 3 . This ammonia is used as a reducing agent in the NOx catalyst 3 . Furthermore, the addition valve 4 may ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com