Solder resist ink composition

An ink composition and resist technology, which is applied in the manufacturing of instruments, electrical components, printed circuits, etc., can solve the problem of poor adhesion between conductor pads and chemical plating layers, and poor adhesion between conductor pads and solder bodies. problems such as poor compatibility, to achieve the effect of improving photocuring properties, good impregnation, and improving operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

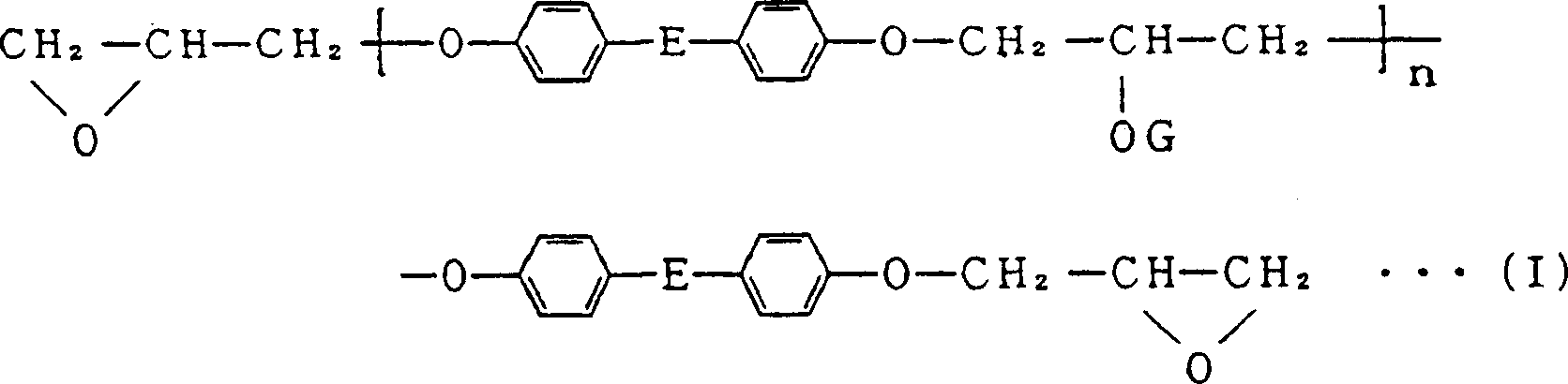

Method used

Image

Examples

Synthetic example 1

[0058] Synthesis example 1 (synthesis example of photosensitive prepolymer (A)):

[0059] 220 parts of Epiclon N-695 (epoxy equivalent = 220 produced by Dainippon Ink Chemical Industry Co., Ltd.) of cresol novolac epoxy resin was placed in a four-necked flask with a stirrer and a reflux cooler, and 206 parts Carbitol acetate, heated to dissolve. Then add 0.1 parts of polymerization inhibitor hydroquinone and 2.0 parts of reaction catalyst triphenylphosphine. This mixture was heated to 95-105 degreeC, and 72 parts of acrylic acid were dripped slowly, and it was made to react for 16 hours. The obtained reaction product was cooled to 80-90 degreeC, 91.2 parts of tetrahydrophthalic anhydrides were added, it was made to react for 8 hours, and it took out after cooling. The photosensitive prepolymer thus obtained having an ethylenically unsaturated bond and a carboxylic acid group had a nonvolatile content of 65%, and an acid value of solid matter of 87.8 mgKOH / g. Hereinafter, th...

Embodiment 1~4

[0061] Using the varnish A obtained in Synthesis Example 1, the ingredients shown in Table 2 were kneaded with a 3-roll mill to obtain a solder resist ink composition.

[0062] Match raw materials

Synthetic example 2

[0116] In a flask equipped with a thermometer, a stirrer, a dropping funnel, and a reflux cooler, add methyl methacrylate, ethyl methacrylate, and methacrylic acid in a molar ratio of 1:1:2, and use dipropylene glycol as a solvent Monoethyl ether, using azobisisobutyronitrile (AIBN) as a catalyst, stirring at 80° C. for 4 hours under a nitrogen atmosphere to obtain a resin solution.

[0117] Cool the resin solution, use methyl hydroquinone as a polymerization inhibitor, tetrabutylphosphonium bromide as a catalyst, and carry out an addition reaction corresponding to 20 mol% of the carboxylic acid groups of the resin at 95 to 105 ° C and 16 hours, Remove after cooling.

[0118] The thus obtained photosensitive prepolymer having an ethyl carboxyl group having an ethylenically unsaturated bond had a non-volatile content of 65%, an acid value of solid content of 120 mgKOH / g, and a Mw of approximately 15,000. This resin solution is hereinafter referred to as B varnish.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com