Dedusting energy-saving coal stove

A technology of charcoal stoves and dust removal pipes, which is applied in the field of stoves, can solve the problems of environmental pollution and waste of energy, and achieve the effects of simple production process, reduced environmental pollution, and low manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

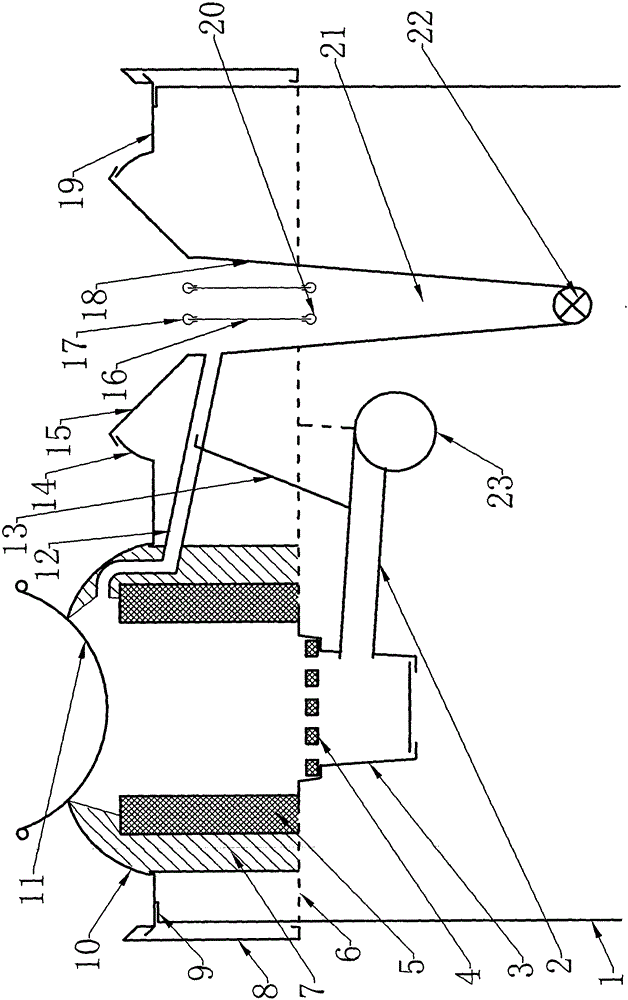

[0014] The accompanying drawings describe the structure of a dust-removing and energy-saving charcoal stove. A dust-removing and energy-saving charcoal stove mainly consists of a charcoal-burning stove and a dust-removing burner. The legs 1, the lower frame 6, and the upper frame 9 jointly form a bracket; the stove shell 8 is fixed with the bracket; the space enclosed by the grate 4, the furnace core 5, the upper part of the refractory layer 7, and the pot 11 is the stove hearth; the furnace core 5 is installed Fixed on the lower frame 6, the furnace core 5 is barrel-shaped, and the shape of the refractory layer 7 is compatible with the furnace core; leg 1, support, stove shell 8, fire grate 4, ash bucket 3, furnace core 5, refractory layer 7, blower 23. The main air duct 2 and the stove fort 10 together form a charcoal-burning stove; one end of the air inlet pipe 13 communicates with the smoke inlet pipe 12, and the other end communicates with the main air duct 2; one end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com