Phase change type heat accumulation electric heater

A thermoelectric and phase change technology, which is used in household heating, heating fuel, heating methods, etc., can solve the problems of poor heat storage effect, high product power, uneven heat dissipation, etc., and achieves large heat storage and lightweight design. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

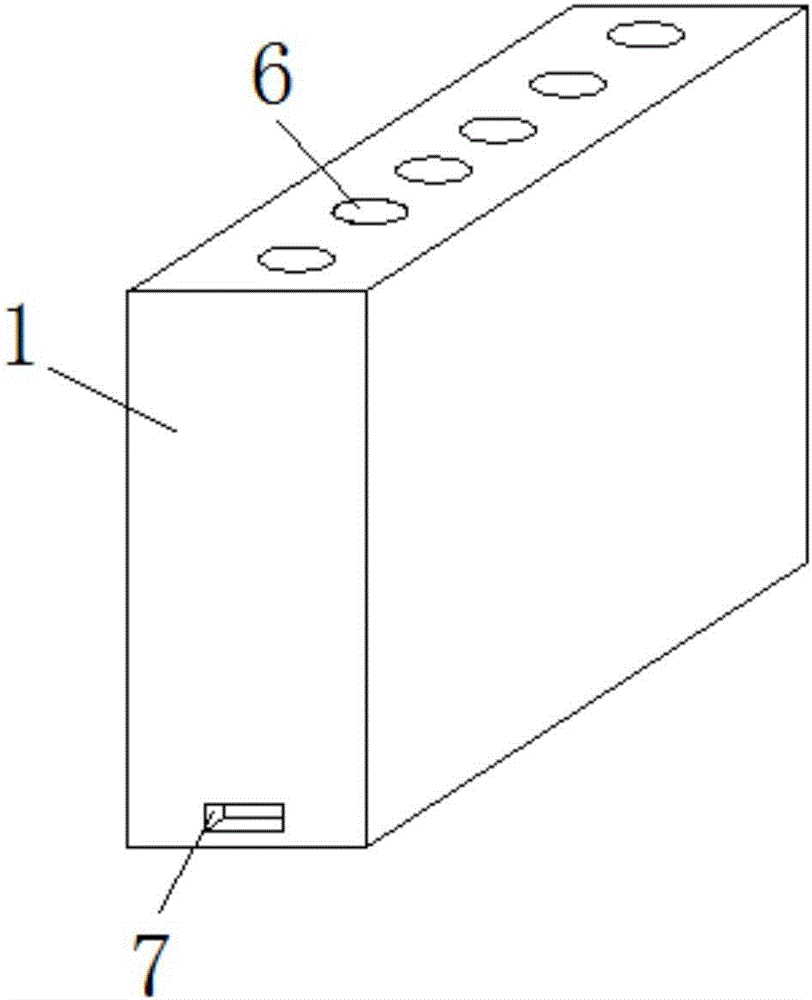

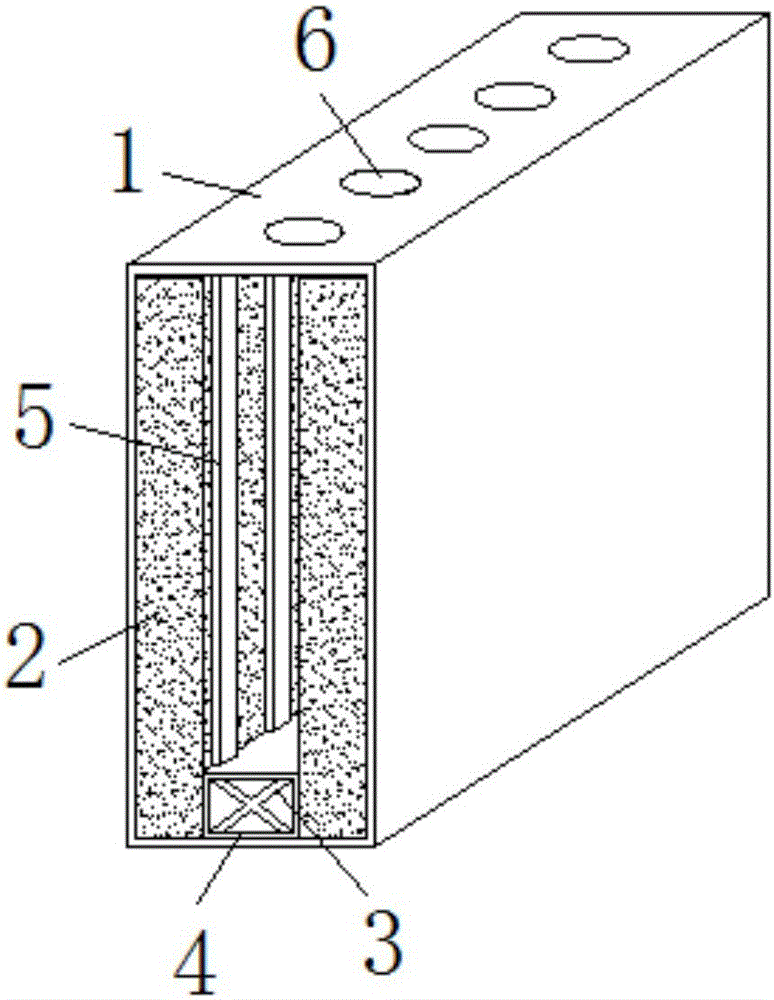

[0015] refer to Figure 1-2 , a phase-change heat storage electric heater, including a shell 1, a box-change heat storage module 2 is installed on both sides of the inner cavity of the shell 1, and the box-change heat storage module 2 is used to store excess heat for use in Continuous heat release, heat dissipation channels are formed between multiple groups of box-type heat storage modules 2, and the heating device sends heat to the outside of the heat dissipation holes 6 through the heat dissipation channels to complete the heating work, and multiple groups of box-type heat storage modules 2 are close to the heat dissipation channels A plurality of heat-conducting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com