Heating stove with blind

A heating furnace and blinds technology, applied in the field of heating furnaces, can solve the problems that the heat cannot be completely dissipated, the heat dissipation is slow, and the heating effect cannot be achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

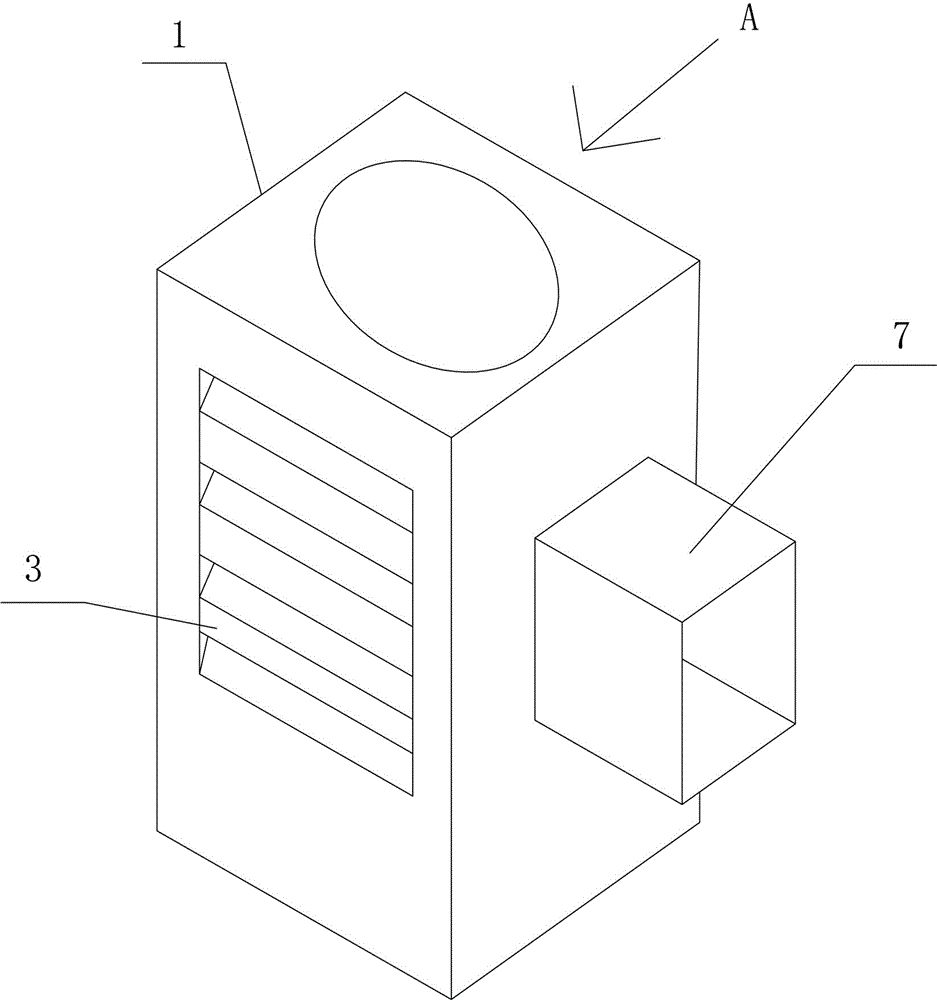

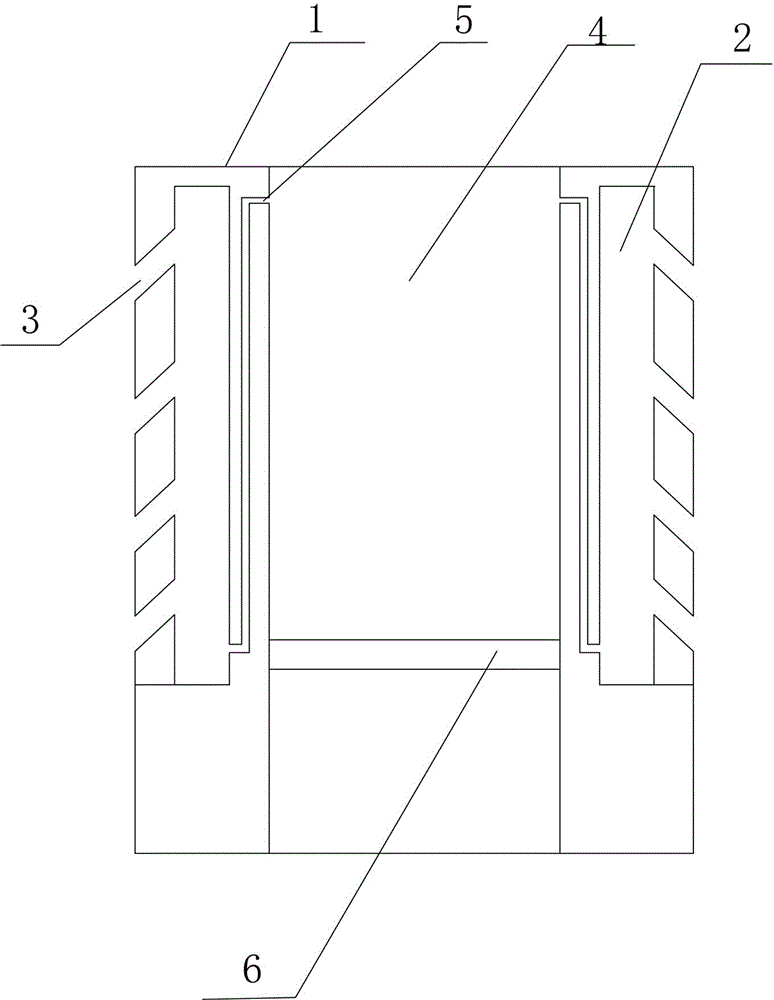

[0013] Such as figure 1 , 2 Among them, a heating furnace with louvers includes a furnace body 1, a hollow interlayer 2 is arranged in the wall of the furnace body 1, and a louver 3 is arranged on the outer surface of the wall of the furnace body 1, and the louver 3 communicates the hollow interlayer 2 with the outside of the furnace body 1. A combustion chamber 4 is arranged inside the body 1, and the furnace bridge 6 divides the combustion chamber 4 into upper and lower parts. The chamber 4 communicates, preferably, the air intake pipe 5 communicates the lower end of the hollow interlayer 2 with the upper end of the combustion chamber 4 .

[0014] A plurality of the inlet pipes 5 are evenly distributed on the wall of the furnace body 1 .

[0015] Working principle: During the ignition process of the furnace body 1, the combustibles are first put into the combustion chamber 4, and then the combustibles are ignited. During this period, the air outside the furnace body 1 can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com