Patents

Literature

40results about How to "Burning effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Intelligent water wall high temperature corrosion preventing system suitable for large power station boiler and method

ActiveCN103712233AReduce intensityBurning has no effectCasings/liningsPower stationMeasurement device

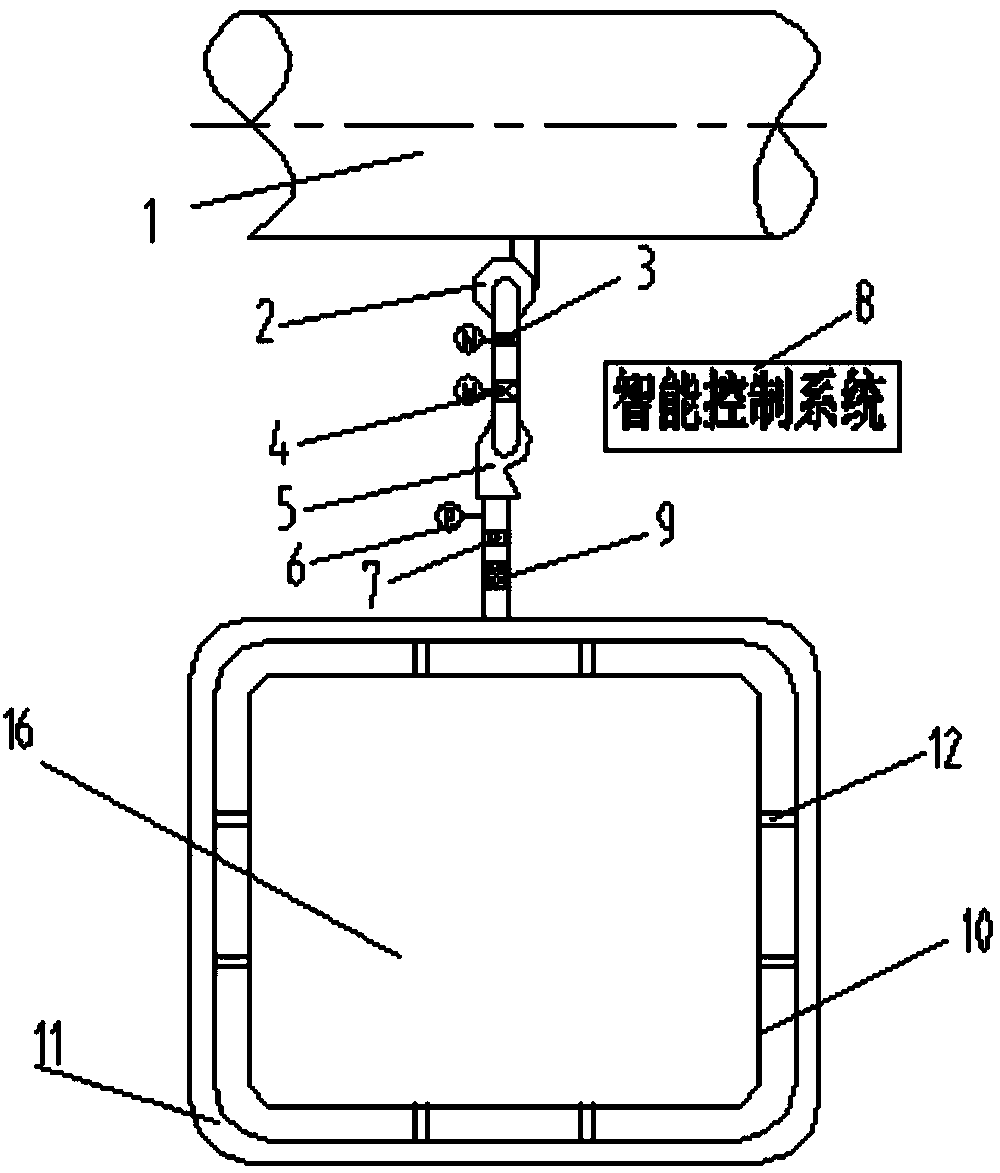

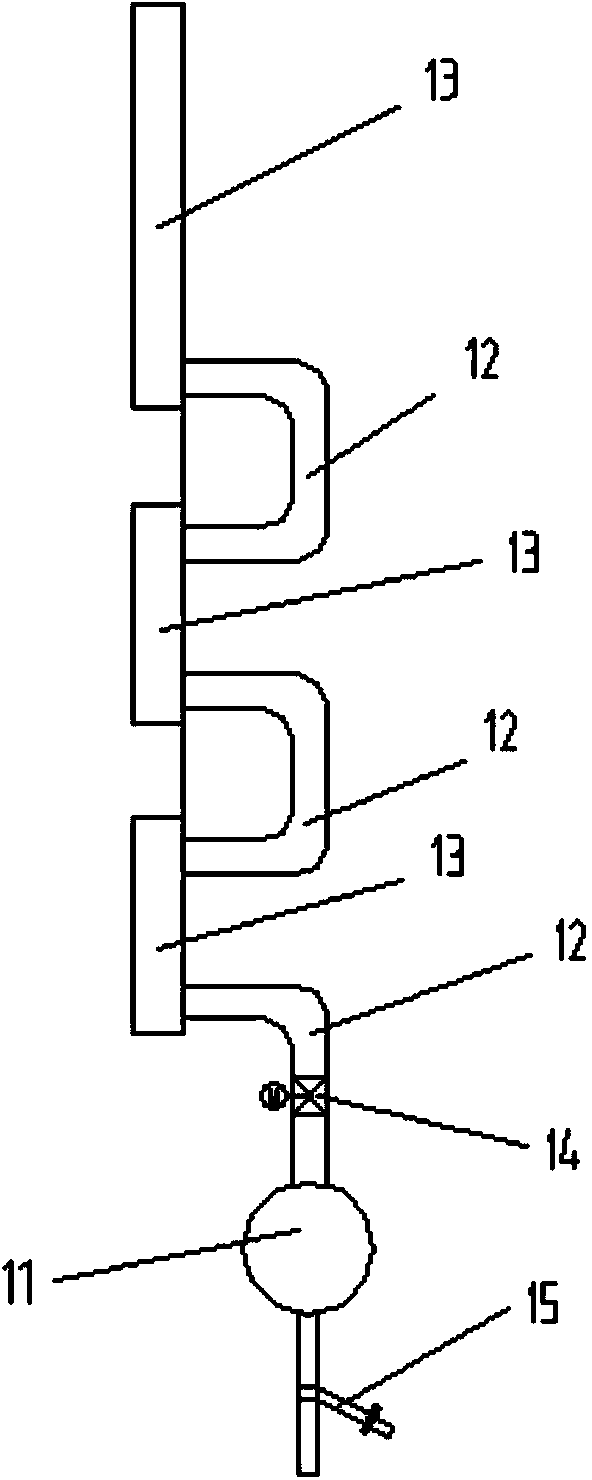

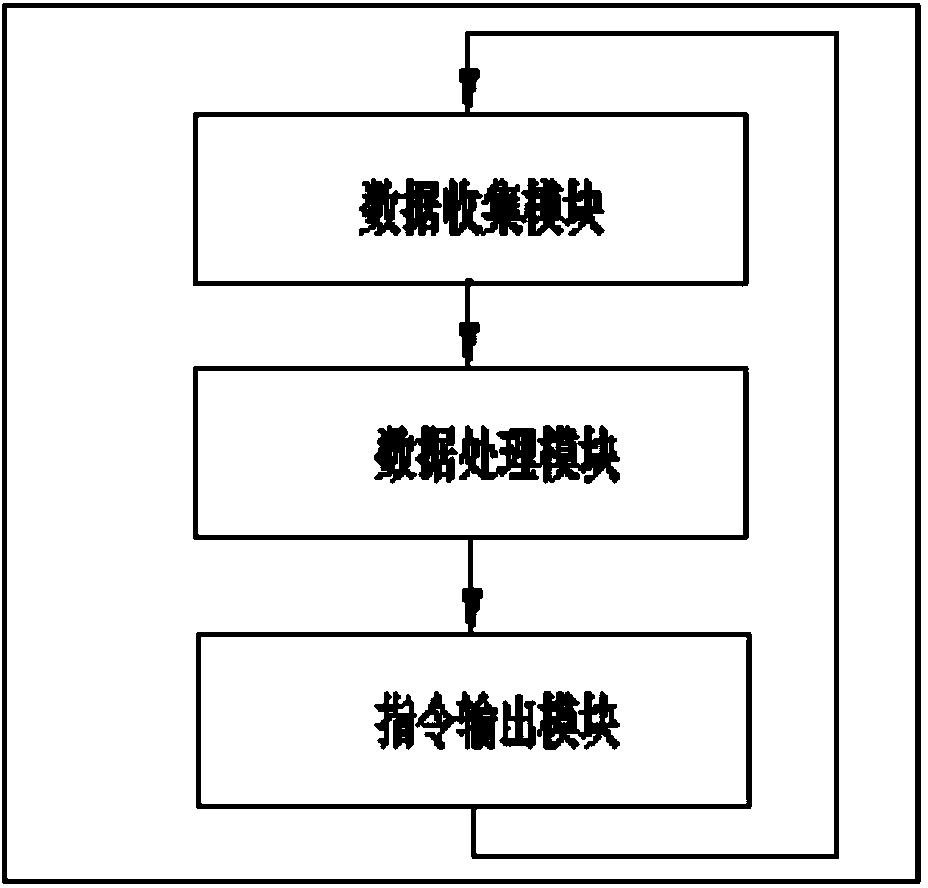

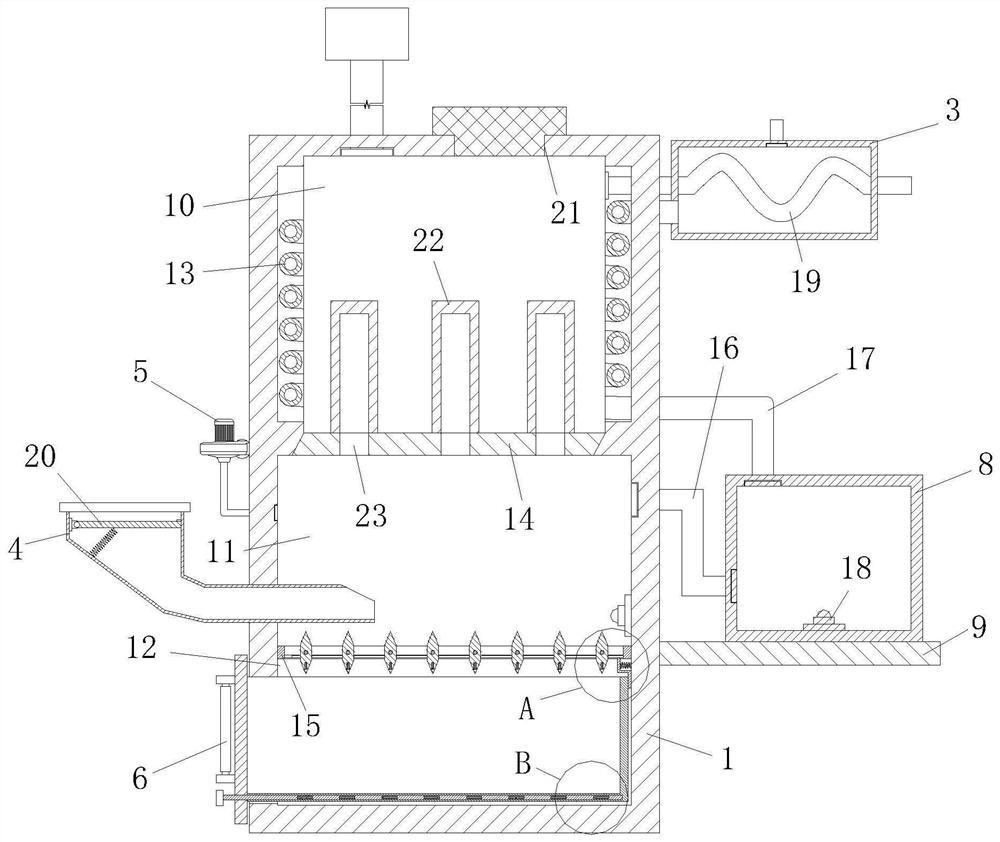

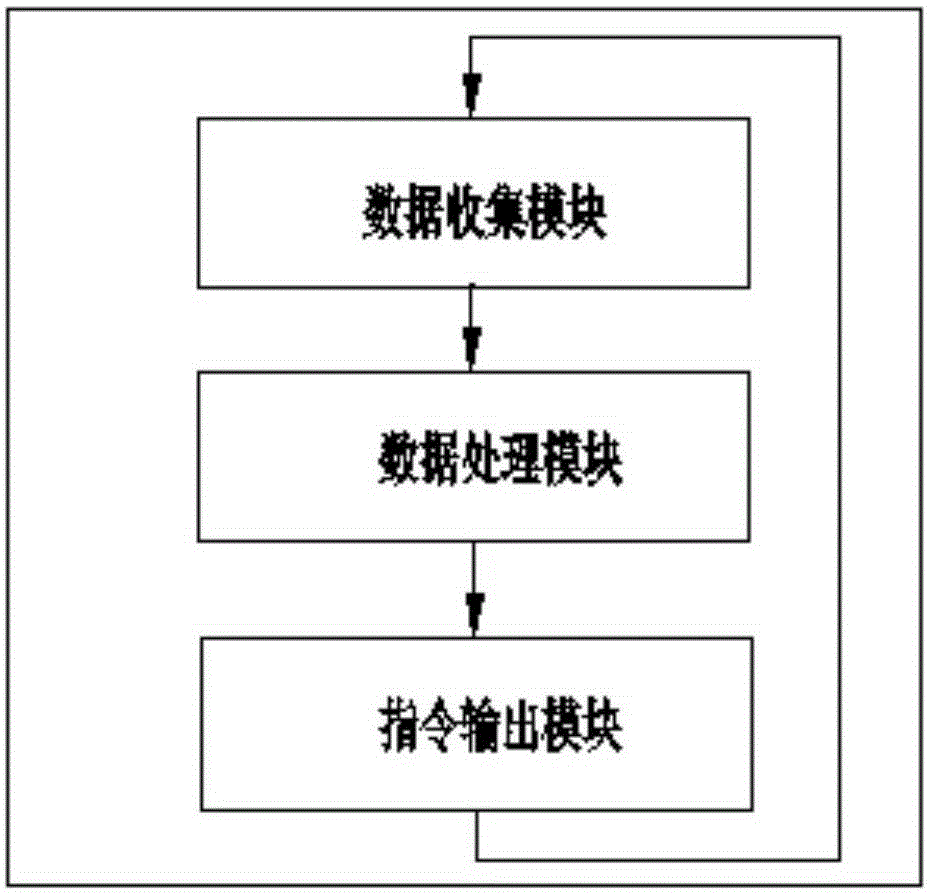

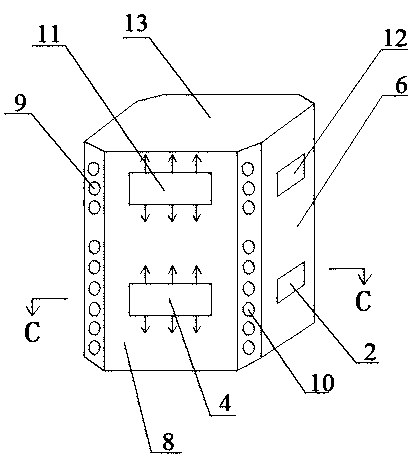

The invention relates to an intelligent water wall high temperature corrosion preventing system suitable for a large power station boiler and a method. The system can be adjusted in real time according to the change of the operating conditions of the boiler to prevent a water wall from high temperature corrosion, operating personnel involvement is not needed, and the high temperature corrosion is intelligently prevented. The system comprises a pressurizing pipeline communicated with an air pre-heater outlet hot secondary air box, a booster fan is arranged on the pressurizing pipeline and is communicated with an annular air box of surrounding a protection wall, the annular air box is communicated with branch air boxes through connecting air boxes, and the branch air boxes are communicated with ventilation grooves in the boiler wall. An air flow adjusting device is arranged on the pressurizing pipeline, and the air flow adjusting device comprises an isolation baffle, a master adjusting baffle, an air flow measuring device and a pressure sensor and further comprises a branch adjusting baffle of the connecting air boxes. An intelligent control system adjusts the opening and closing degree of each baffle in the air flow adjusting device according to the operating state of the boiler, and the air flow is controlled to prevent the water wall from the high temperature corrosion.

Owner:STATE GRID CORP OF CHINA +1

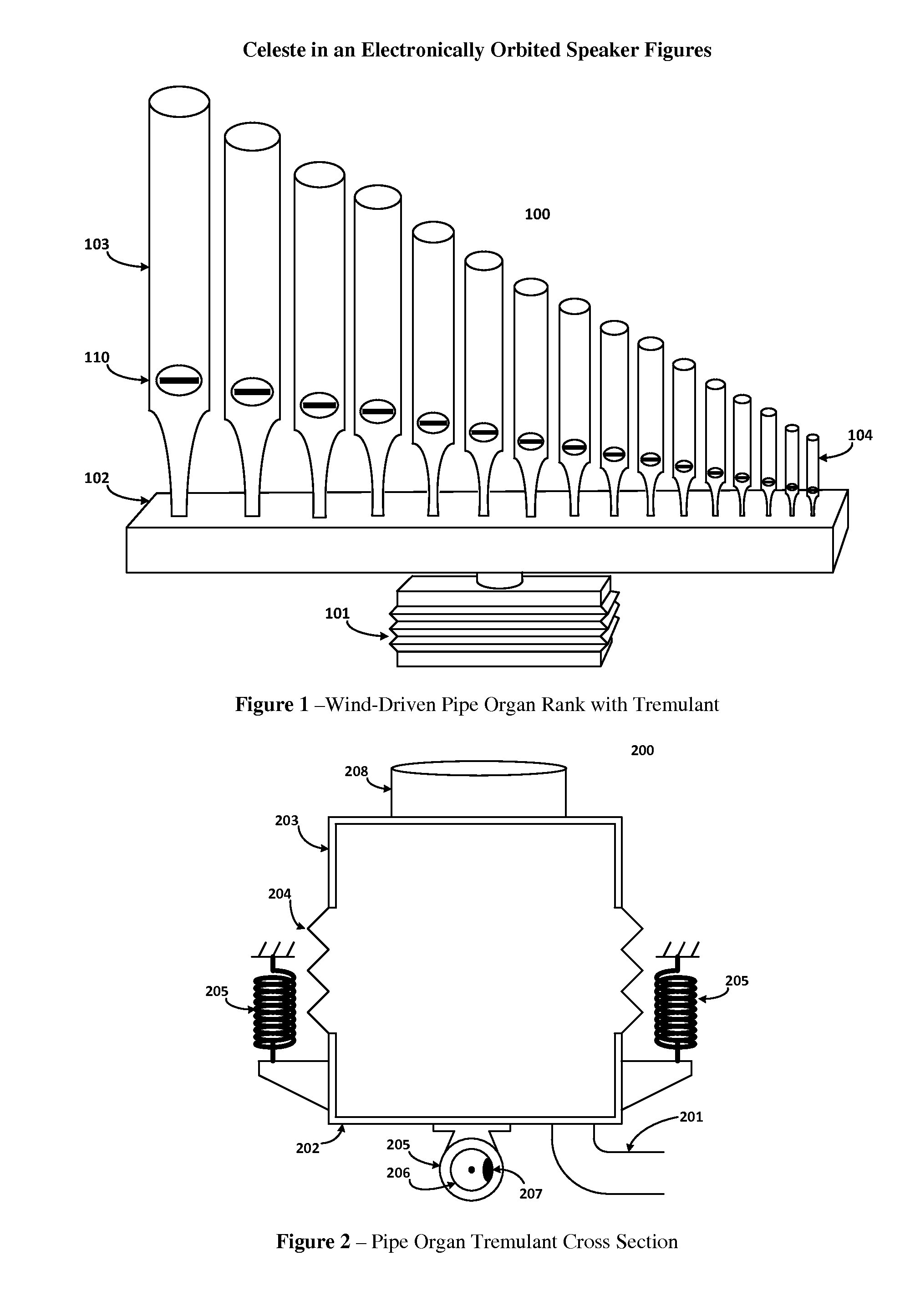

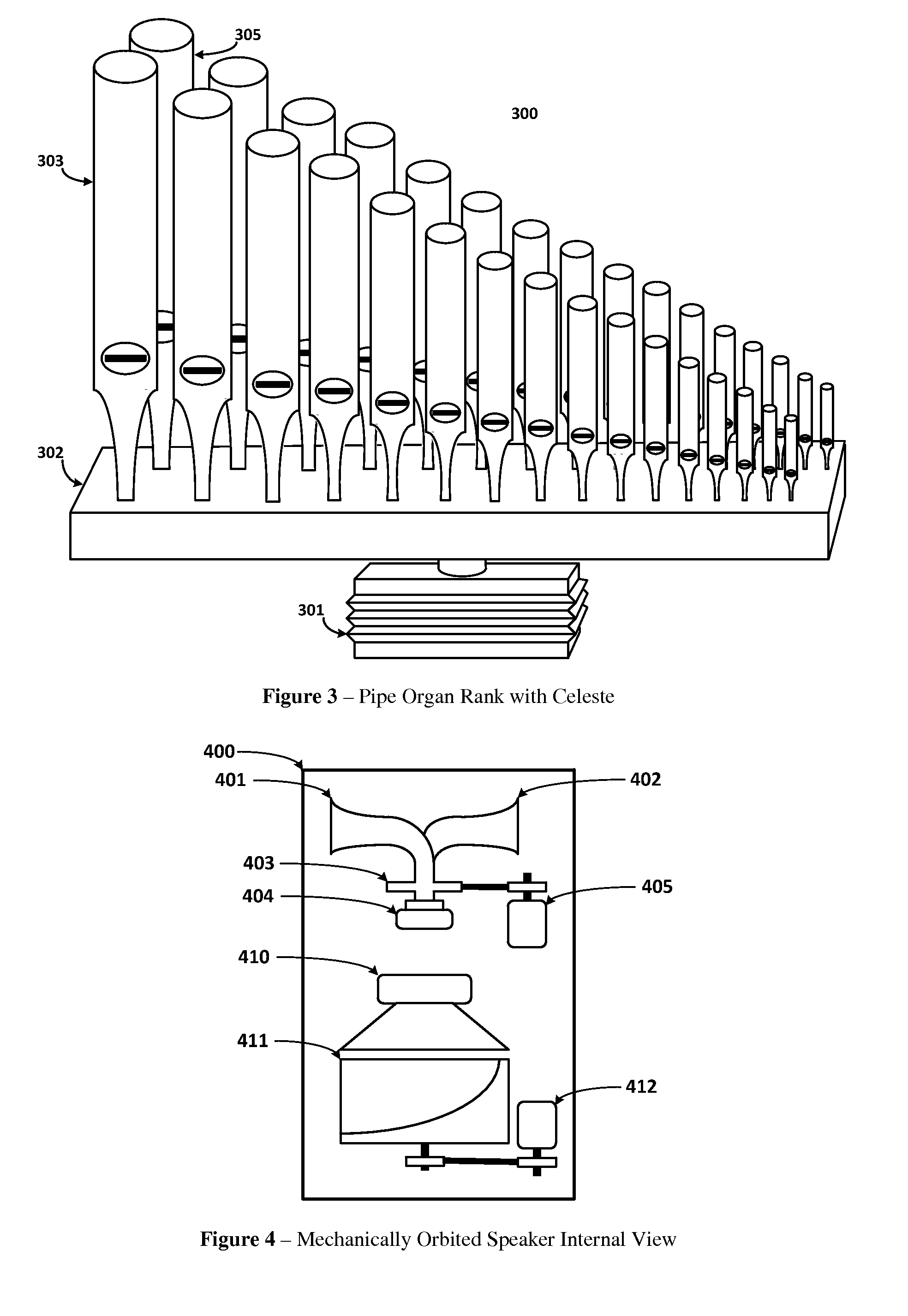

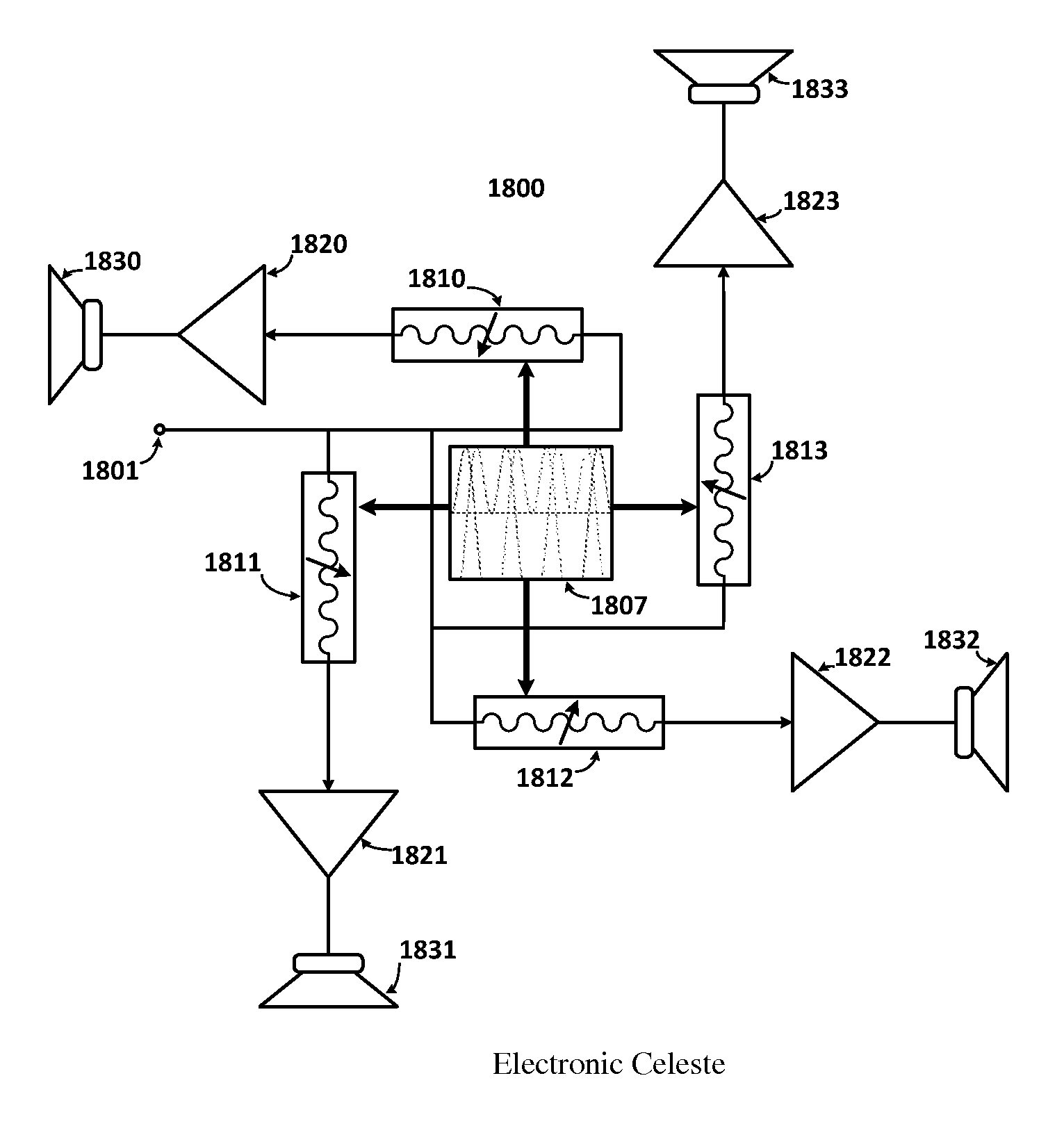

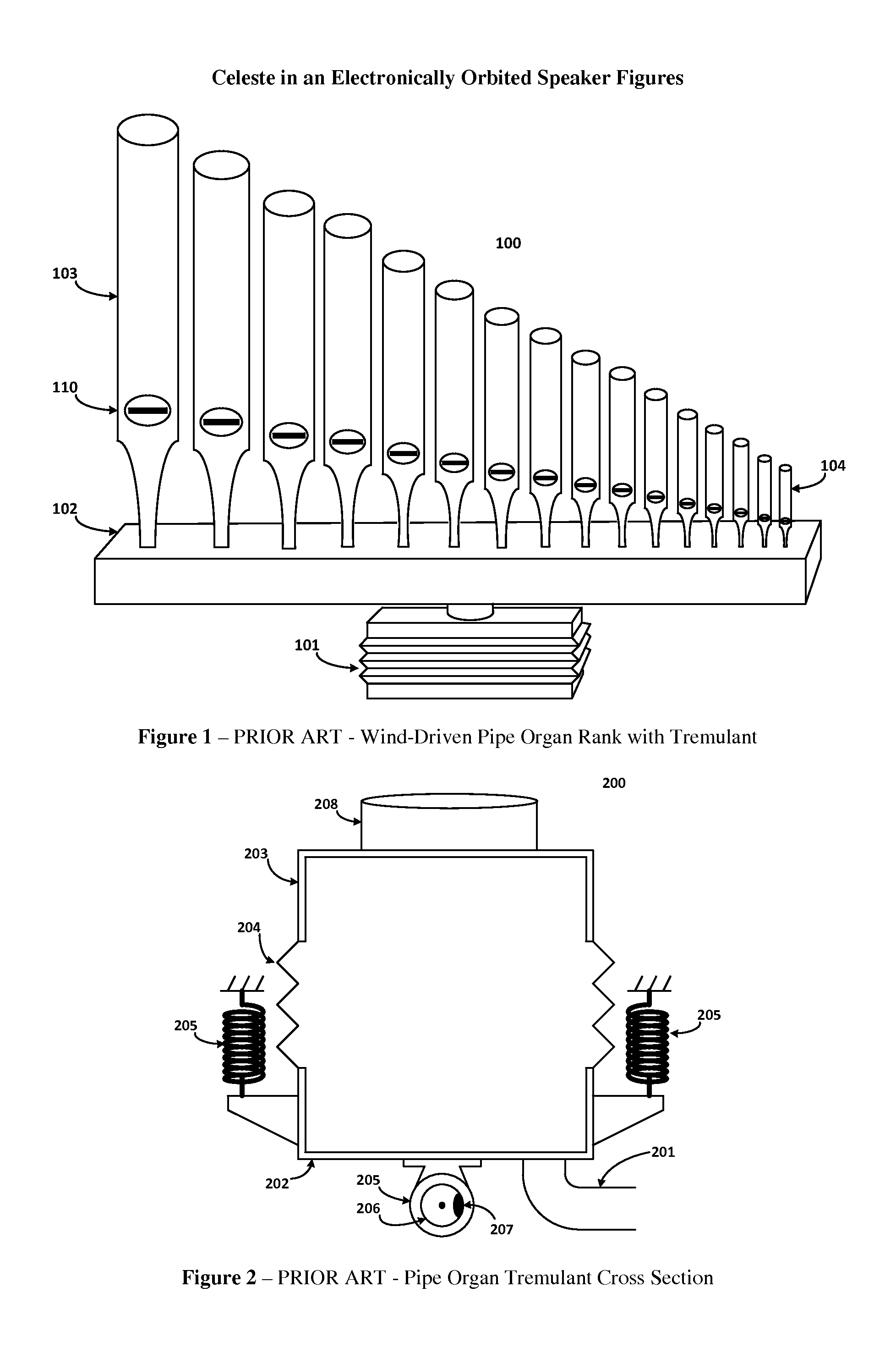

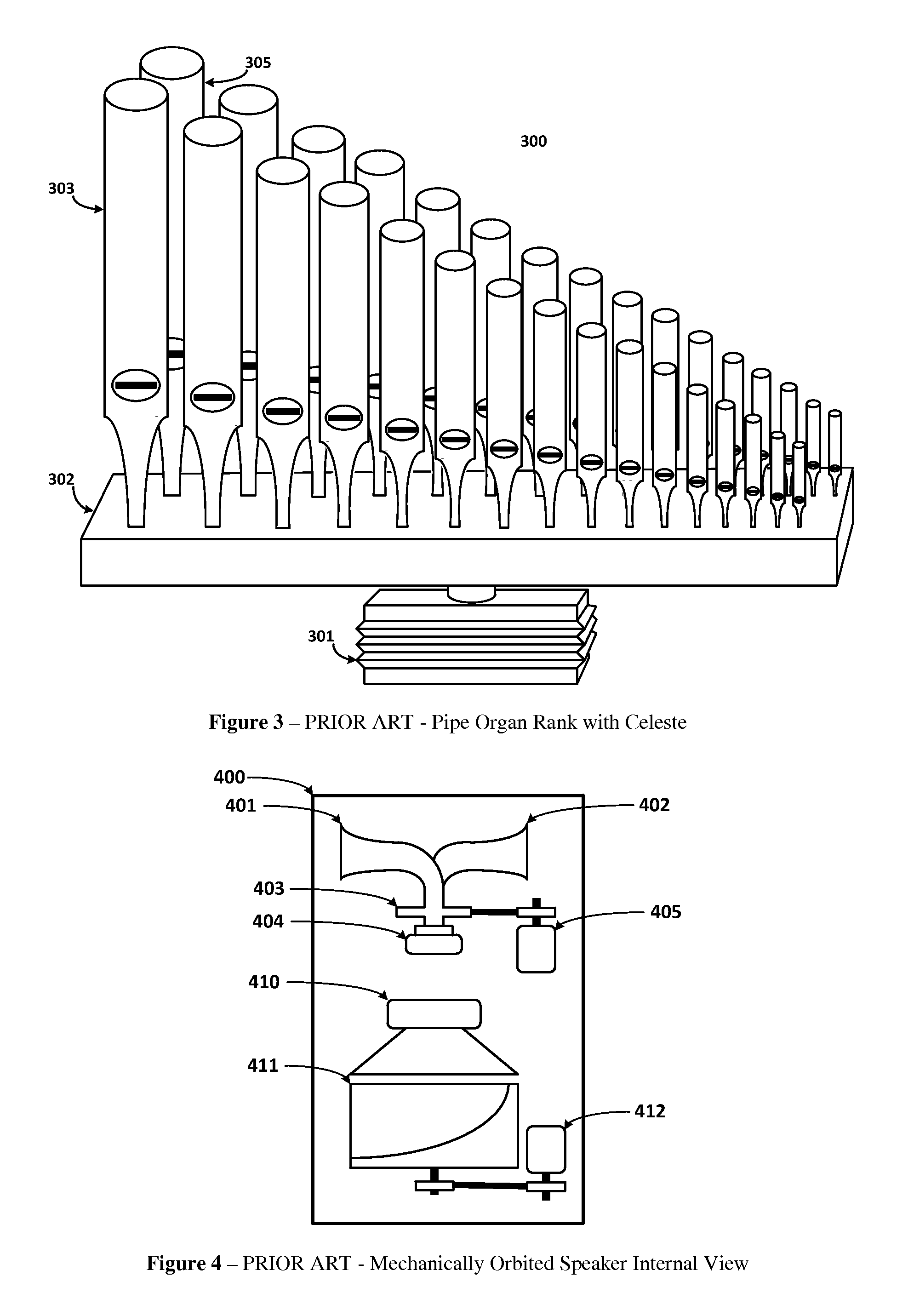

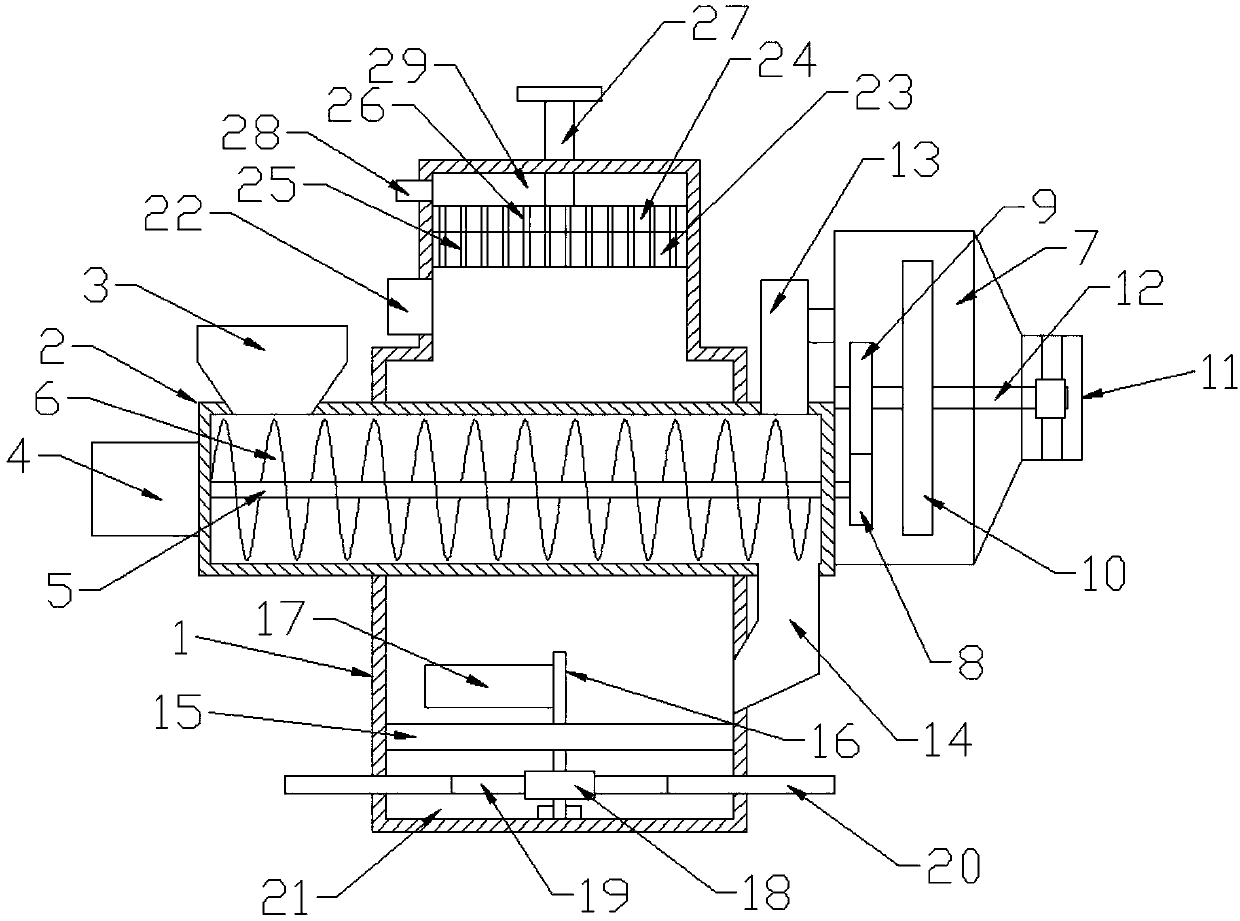

Apparatus and Method for a Celeste in an Electronically-Orbited Speaker

ActiveUS20150071451A1Light-weight portabilityReduce maintenanceSignal processingGain controlSound sourcesAudio power amplifier

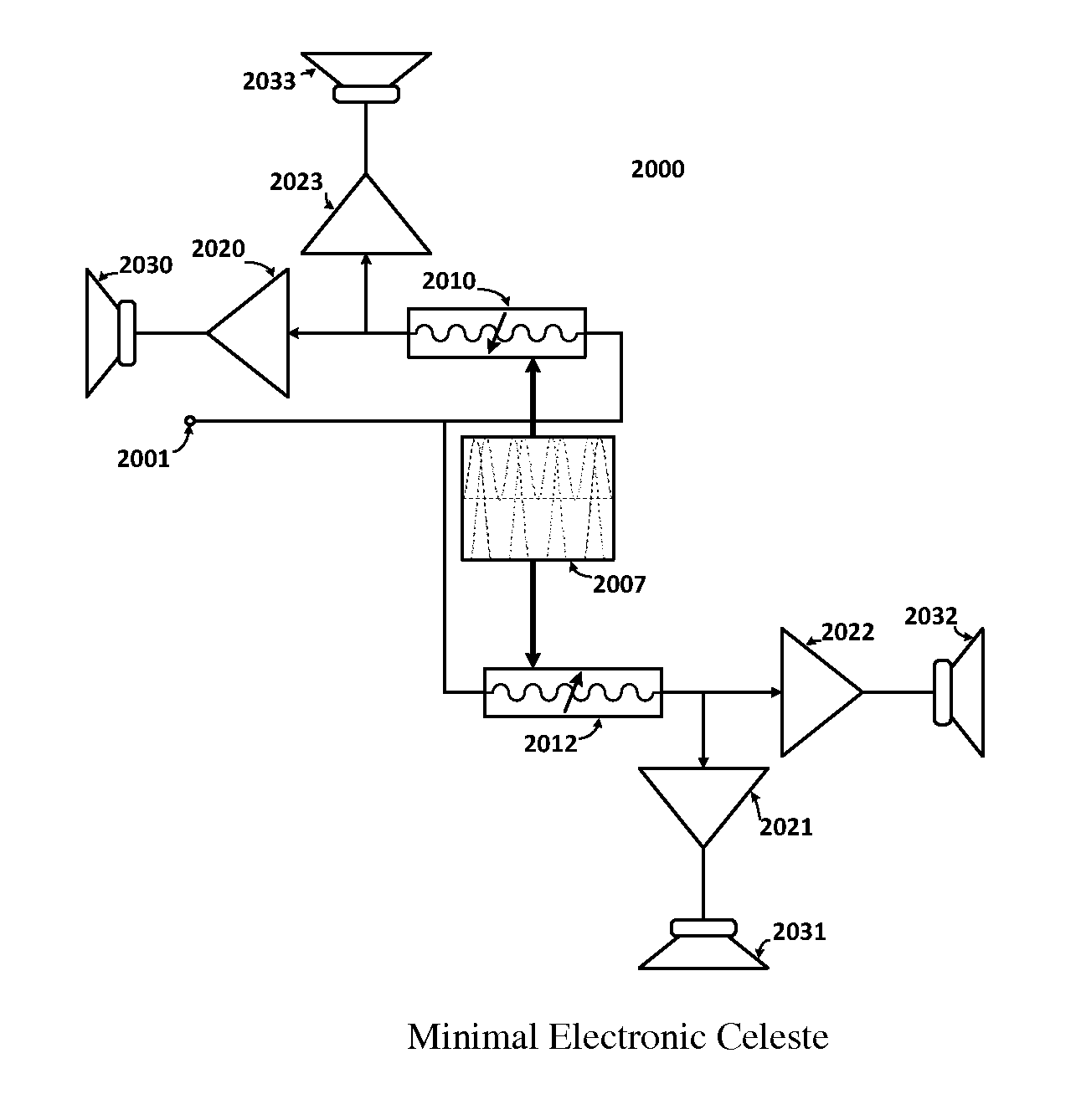

Exemplary embodiments are directed to a sound modification system and loud speaker system. The system may impose amplitude, frequency and delay modulation on a signal representing the output of an musical instrument or other sound source while also imposing a sense of movement of the sound to the listener and a periodic variation of the harmonic content of the sound. Further, the system may simultaneously amplify sound signals without the amplitude, frequency, delay and spatial sense of modulation or a different sense of modulation. The system combines a plurality of sound transducers, a plurality of amplifiers and signal processors to provide a flexible, portable and practical sound modification and amplification system.

Owner:MOON NANCY DIANE

Apparatus and method for a celeste in an electronically-orbited speaker

ActiveUS9286863B2Light-weight portabilityReduce maintenanceSignal processingGain controlAudio power amplifierSound sources

Exemplary embodiments are directed to a sound modification system and loud speaker system. The system may impose amplitude, frequency and delay modulation on a signal representing the output of an musical instrument or other sound source while also imposing a sense of movement of the sound to the listener and a periodic variation of the harmonic content of the sound. Further, the system may simultaneously amplify sound signals without the amplitude, frequency, delay and spatial sense of modulation or a different sense of modulation. The system combines a plurality of sound transducers, a plurality of amplifiers and signal processors to provide a flexible, portable and practical sound modification and amplification system.

Owner:MOON NANCY DIANE

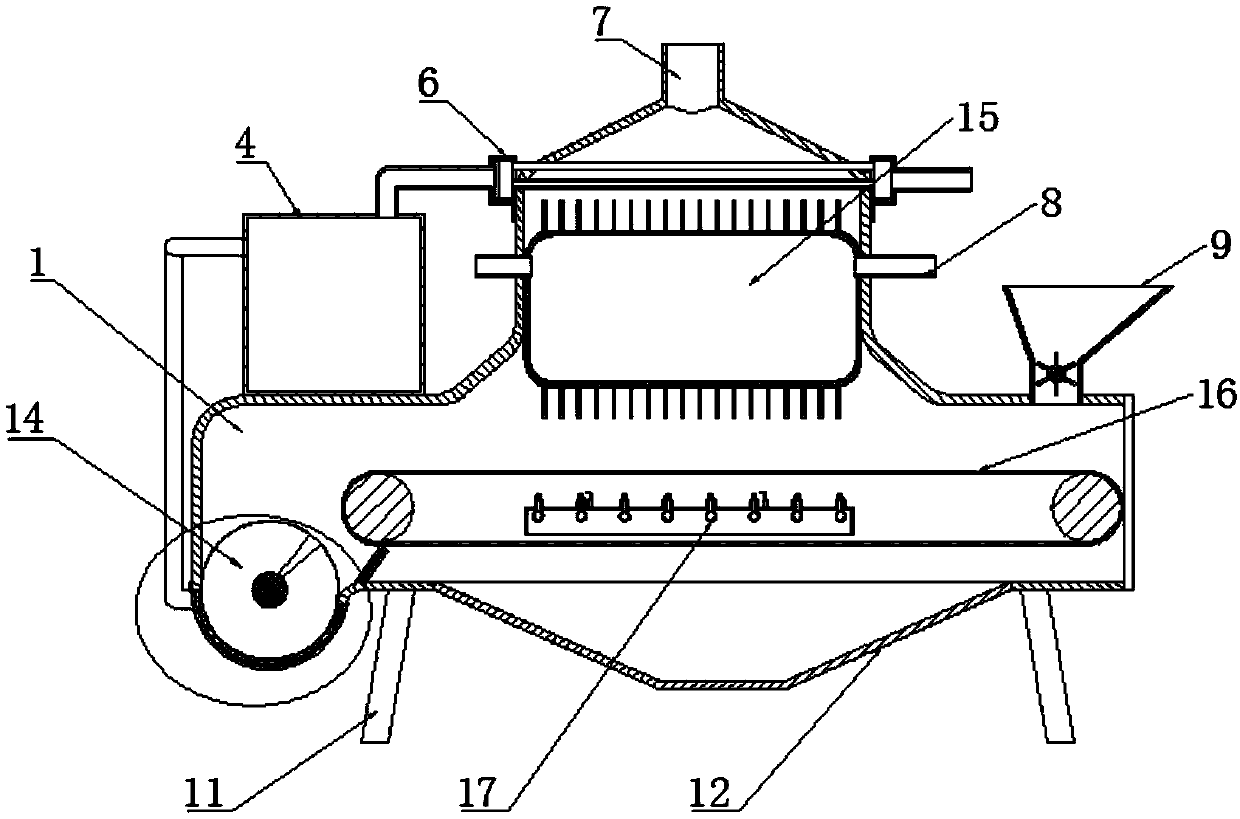

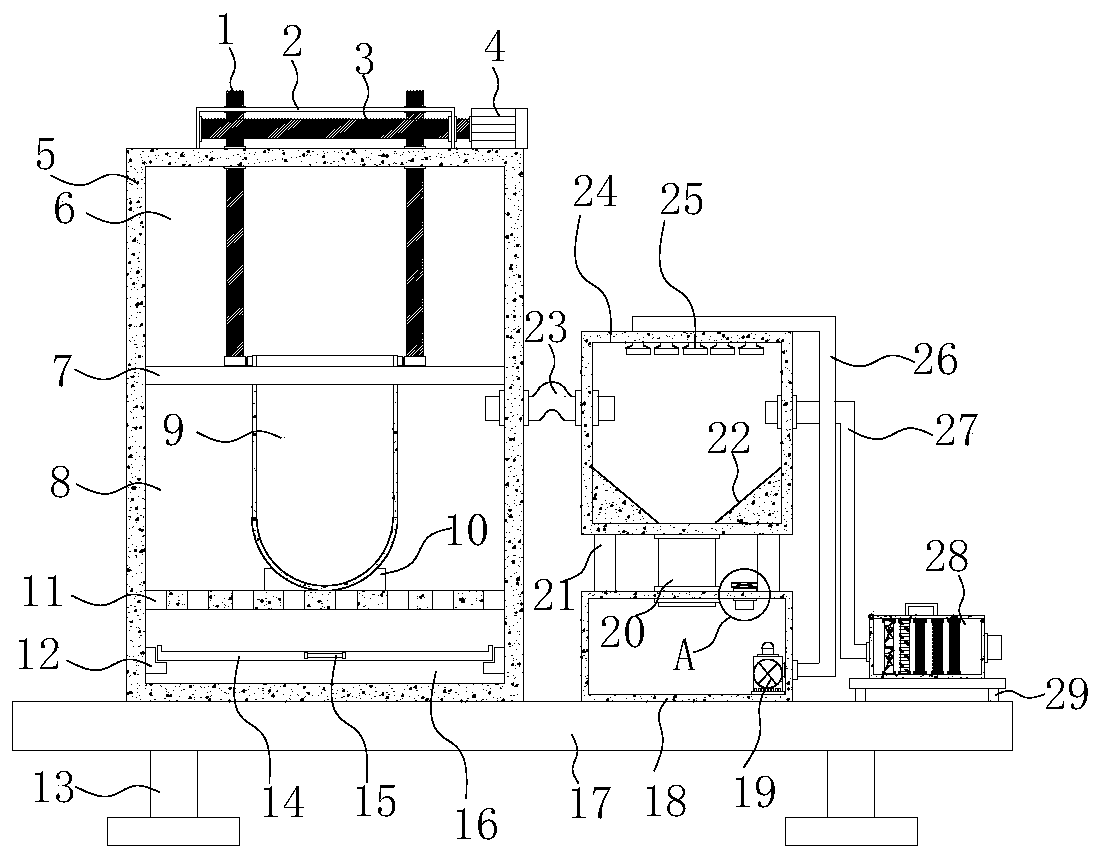

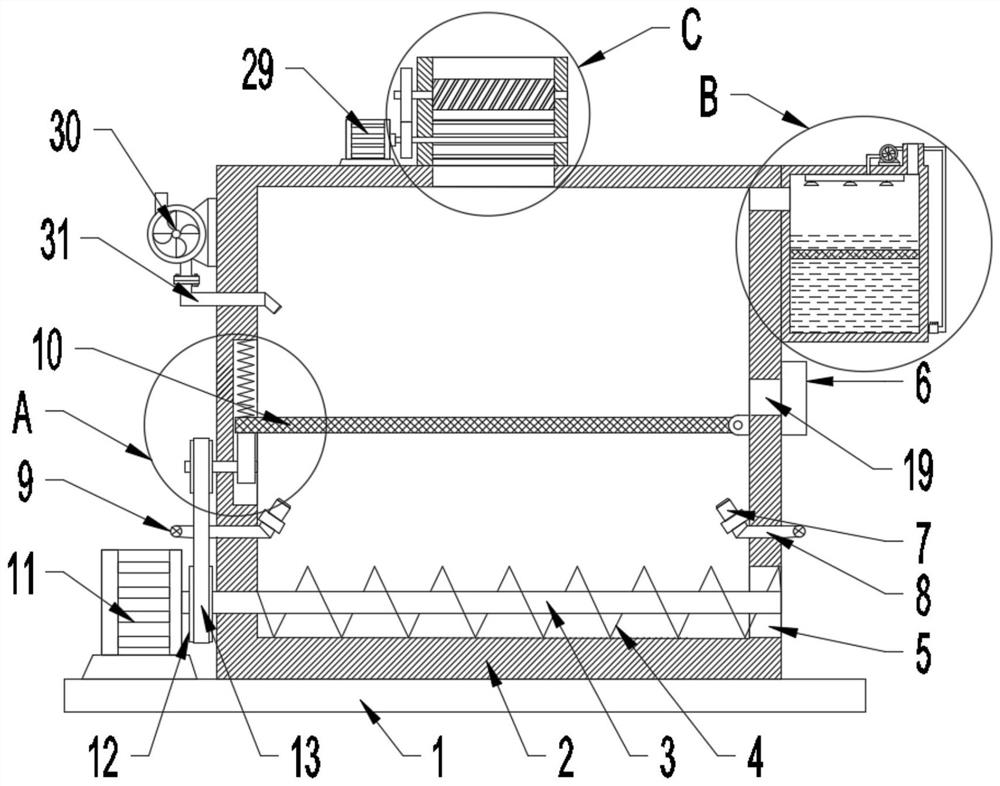

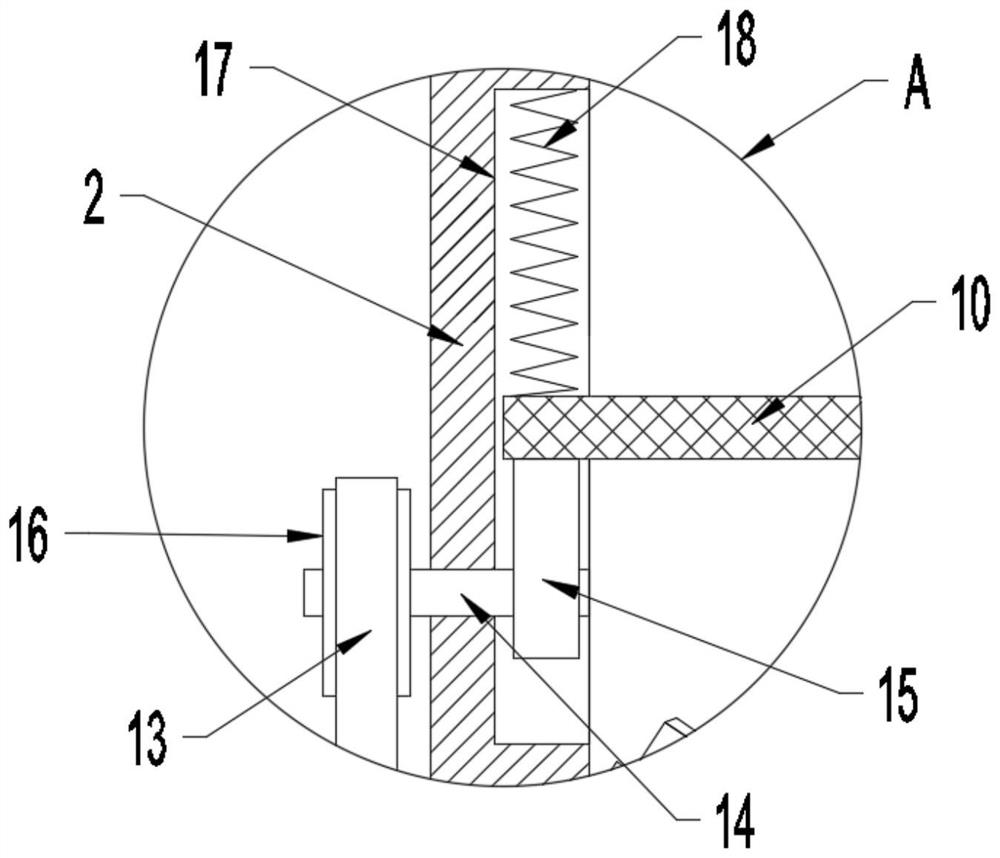

Garbage processing incinerator capable of preheating and dewatering

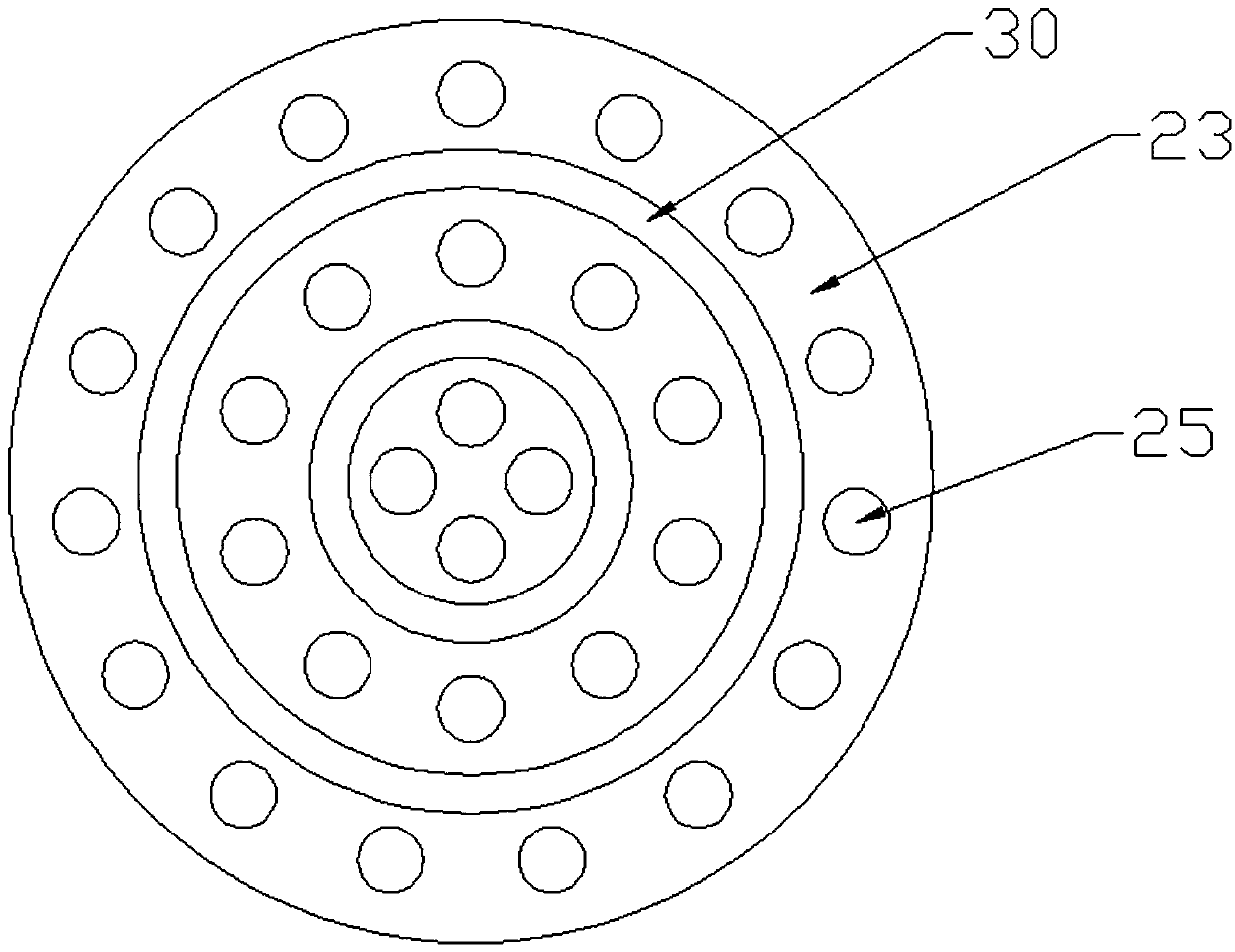

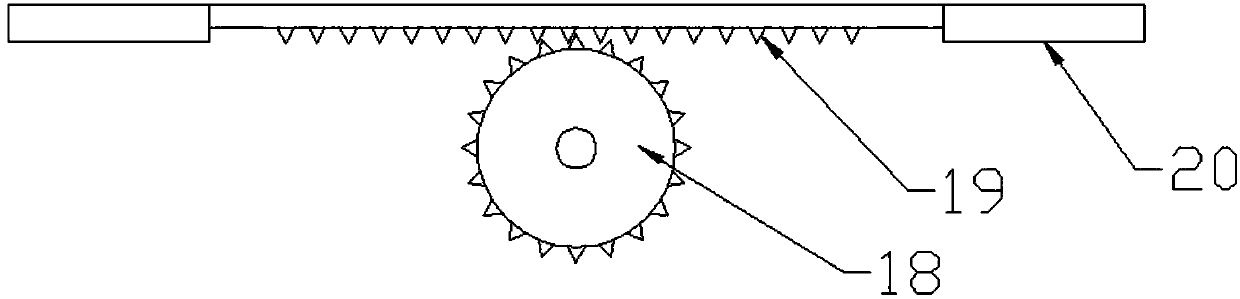

The invention discloses a garbage treatment incinerator for preheating and dewatering, which comprises a shell, a drying cylinder, a feeding hopper and a motor; the drying cylinder is horizontally installed on the upper part of the shell; There are helical blades, and a feeding pipe is connected to the lower side of the other end of the drying cylinder. The drying cylinder is also connected to a steam outlet pipe, and the other end of the steam outlet pipe is connected to a suction hood. A material shifting plate is fixed above the grate; a horizontal fixed plate is fixed in the water cavity, and a rotating plate is arranged on the upper surface of the fixed plate. The invention uses the heat generated by combustion to preheat the incoming garbage through the drying cylinder installed in the housing, so that the water in the interior evaporates, reducing the water in the garbage, so that the garbage can be easily burned when it enters the interior, and the garbage can be easily burned. It is easier to burn, improves the garbage disposal capacity, releases heat, and reduces the toxic gas produced by incomplete combustion to avoid polluting the environment.

Owner:雷晓琴

Efficient energy-saving rotary waste fuel water heating furnace

The invention discloses an efficient energy-saving rotary waste fuel water heating furnace which comprises a water inlet pipe, a shell, a smashing machine, a rotary drum, smashing knives, a combustionfurnace, an air inlet pipe, a rotary circular table, a heat exchange pipe, an air outlet pipe and a water outlet pipe. The combustion furnace is arranged inside the shell, a rotary motor is arrangedat the bottom end inside the combustion furnace, an output shaft of the rotary motor is connected with a rotating shaft, the top end is provided with the rotary circular table, air holes are evenly formed in the rotary circular table, the upper surface of the rotary circular table is provided with multiple electronic igniters, the rotary drum is arranged inside the smashing machine, the outer wallof the rotary drum is evenly provided with the smashing knives, the top end of the combustion furnace is provided with a secondary igniter, the top end of the combustion furnace is connected with oneend of the heat exchange pipe, the other end of the heat exchange pipe communicates with the air outlet pipe, the outer wall of the combustion furnace is wound by the heat exchange pipe, and the outlet end of the air outlet pipe is provided with gas spray head, The heating effect is improved, energy waste is avoided, energy is greatly saved, heat loss is reduced, the energy utilization rate is improved, the structure is simple, use is convenient, energy is saved, and popularization is facilitated.

Owner:赵小波

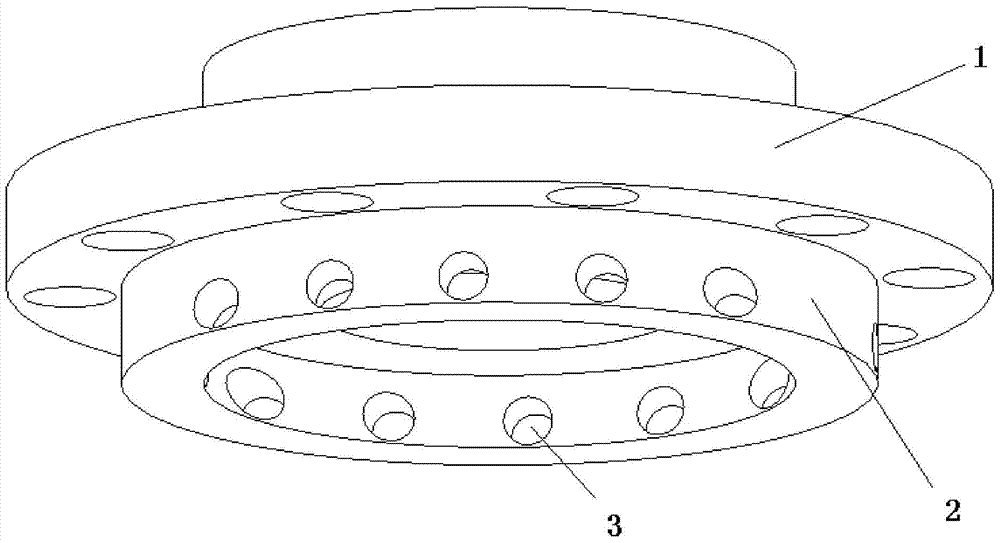

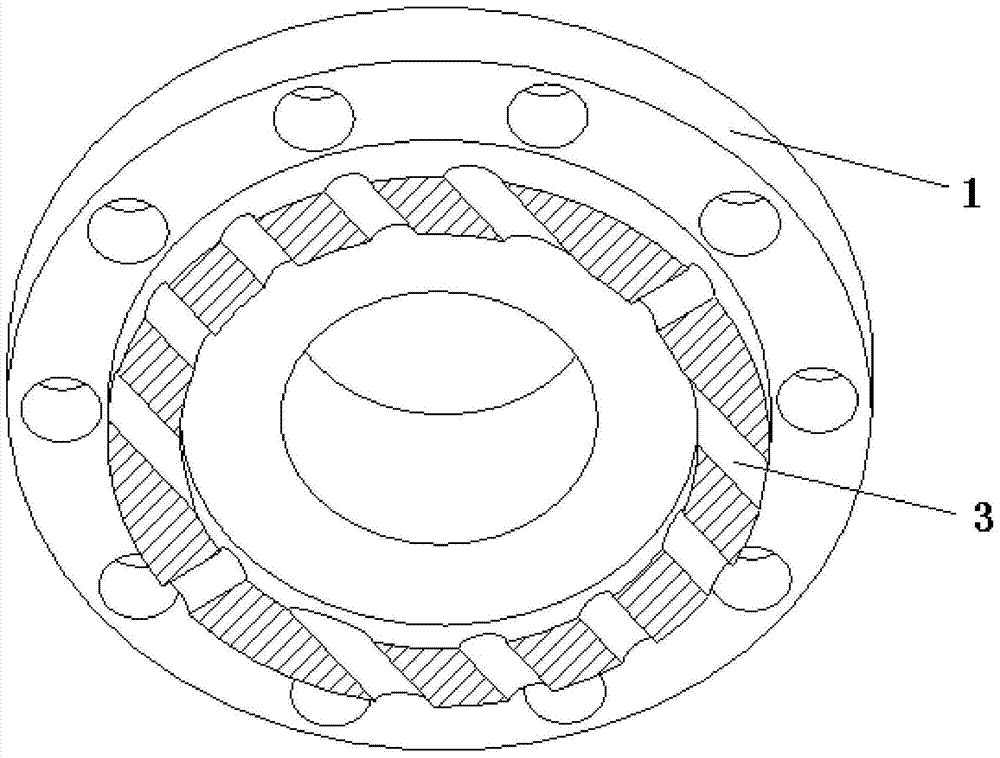

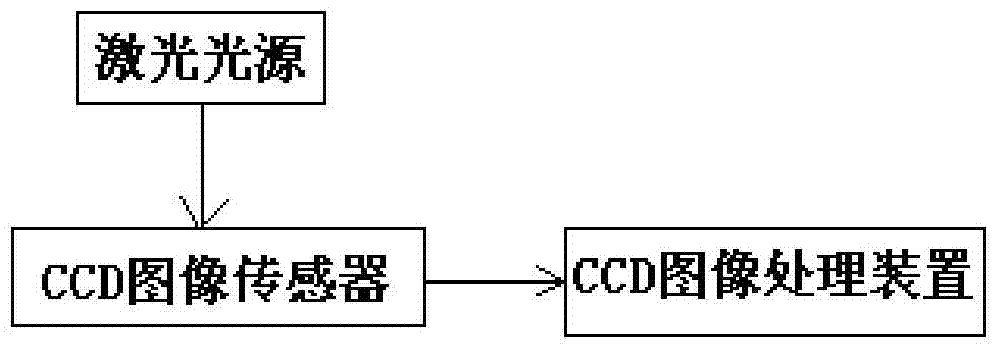

Cylinder internal flow field visualization cylinder cover and method of large diesel engine

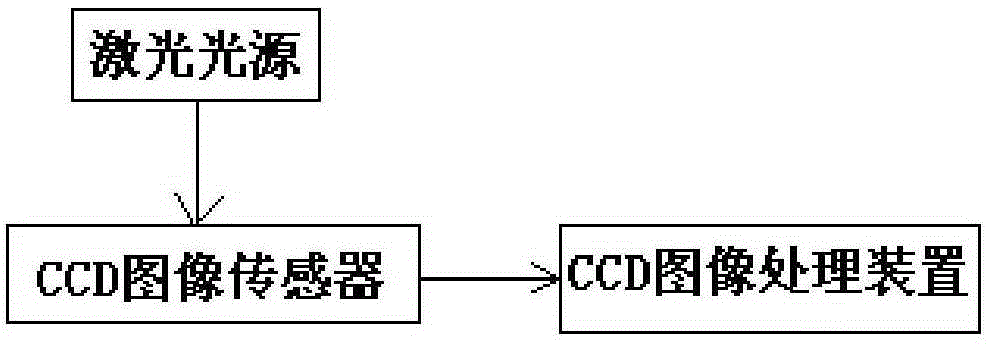

InactiveCN105179099ADegree of renovationLarge flow field areaEngine testingCylinder headsLaser lightFluid field

The invention discloses a cylinder internal flow field visualization cylinder cover and method of a large diesel engine. The cylinder cover is provided with an annular inner edge. A plurality of pairs of through holes are symmetrically formed in the peripheral wall of the annular inner edge in the radial direction, and a laser light source is installed in one through hole. The laser light source is used for collecting the information of a cylinder internal flow field in the fuel injection process. CCD image sensors are installed in the through holes in the opposite side of the laser light source and used for receiving the information, sent by the laser light source, of the cylinder internal flow field and transmitting the information to an external CCD image processing device to be processed. One or two or more through holes of different angles can be selected at will in the opposite face of the placement of the laser light source for containing the CCD image sensors, and therefore the situation of the cylinder internal flow field can be observed from a plurality of angles, and the analysis accuracy is improved. Other through holes not used temporally are sealed and filled with metal sealing components, and therefore the influence on fuel combustion is prevented.

Owner:SOUTH CHINA UNIV OF TECH

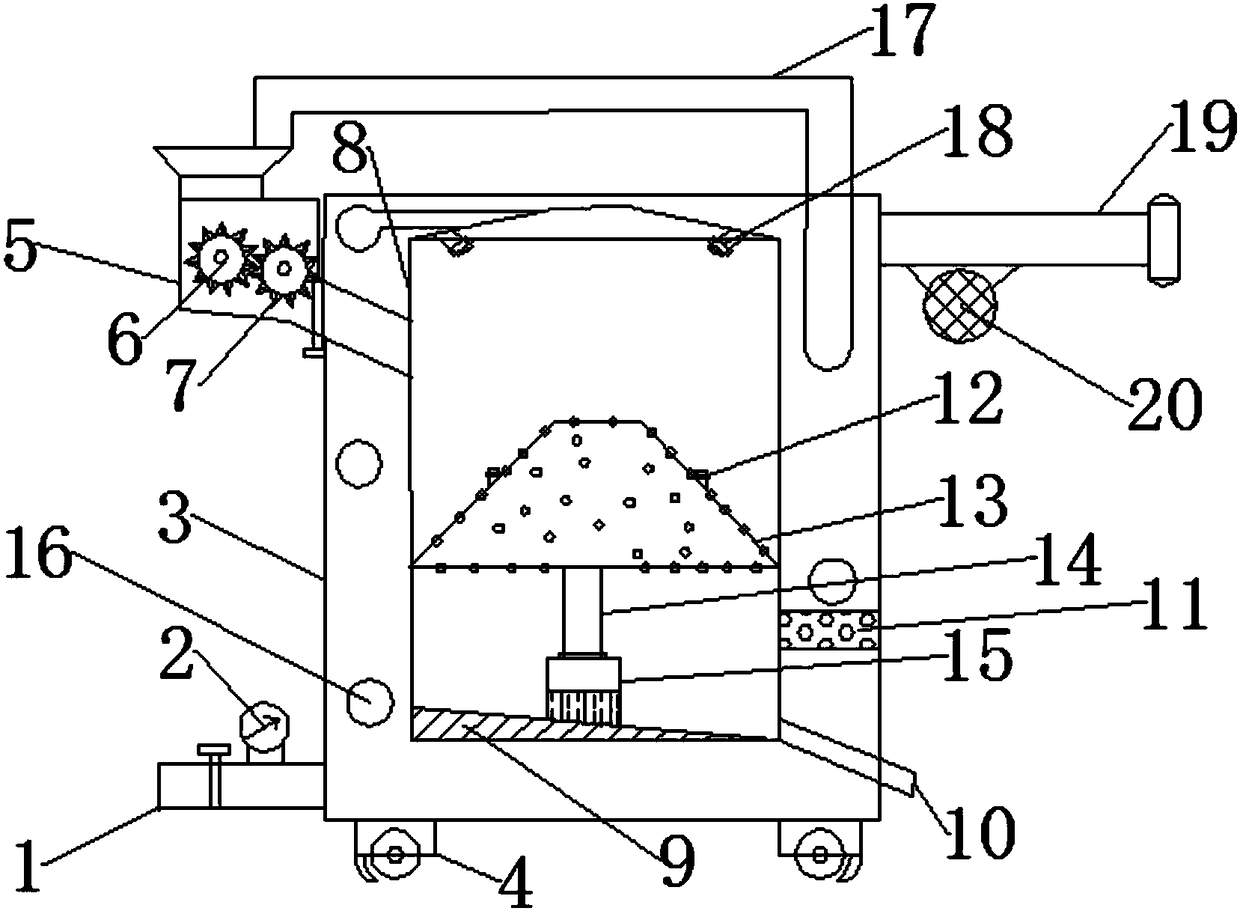

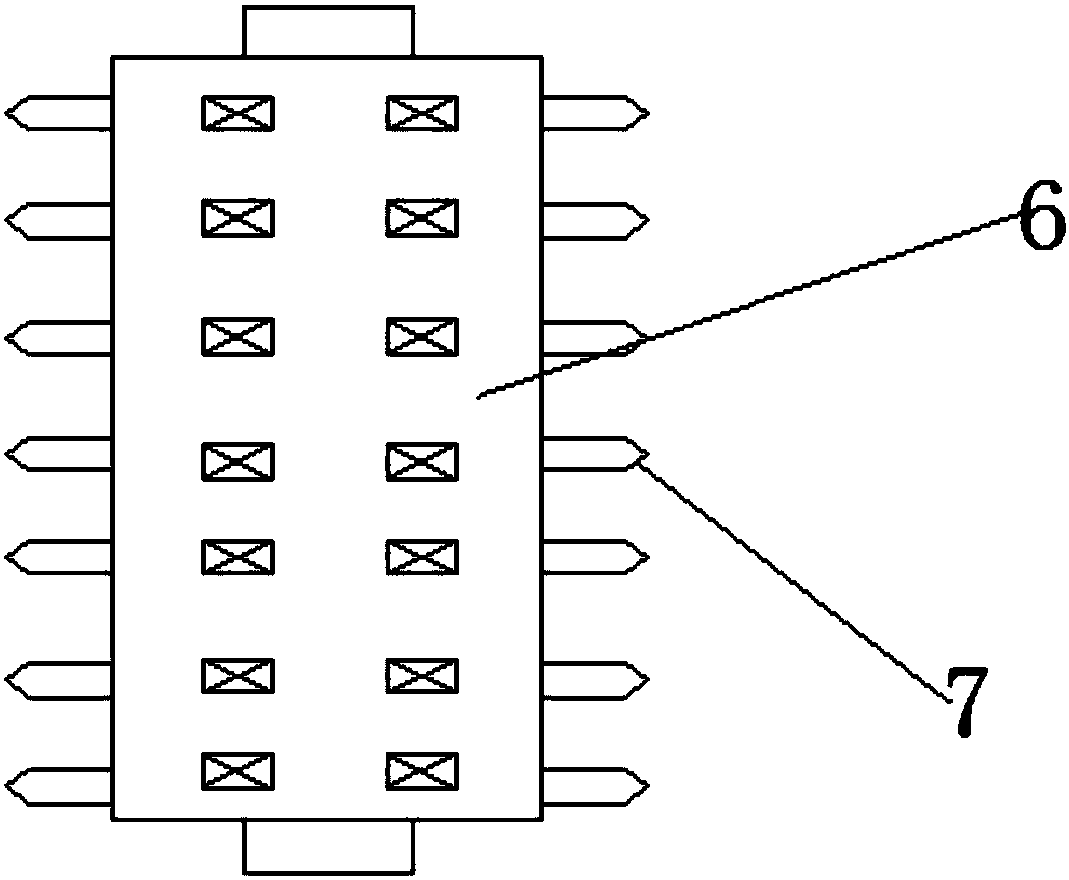

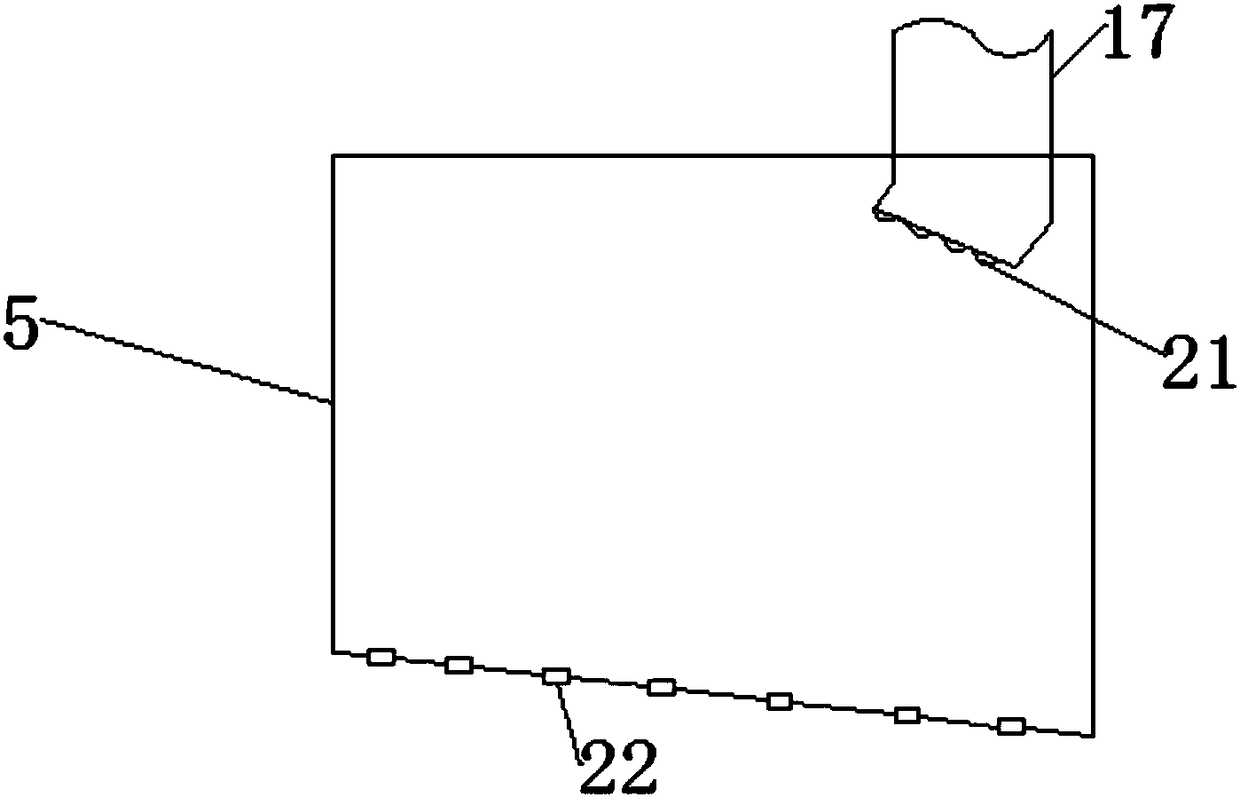

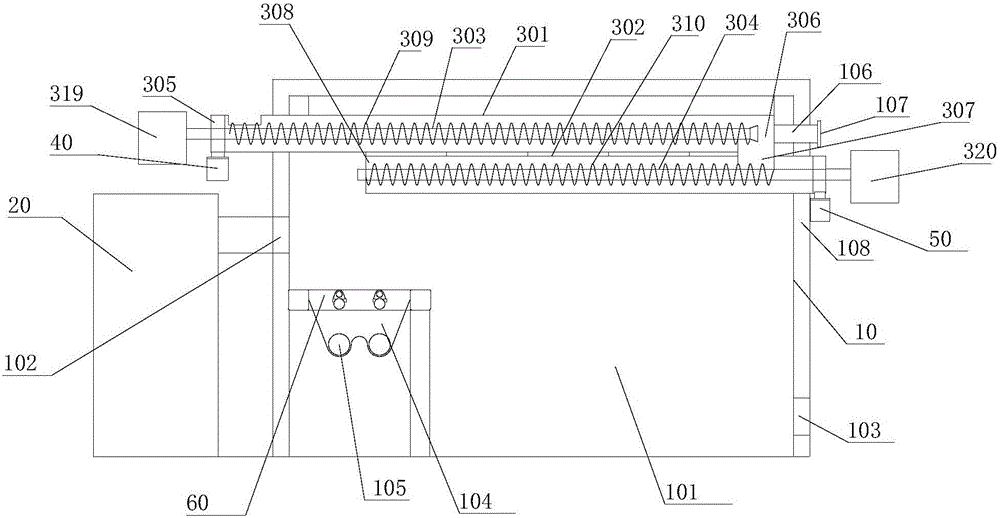

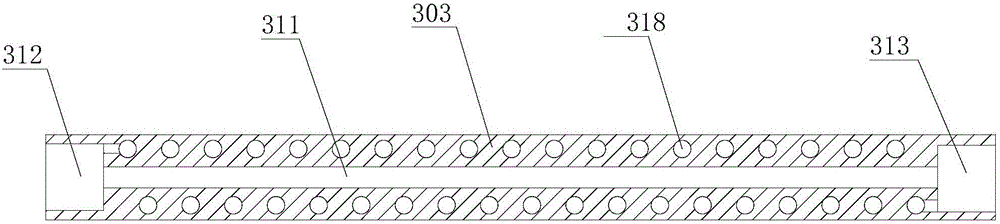

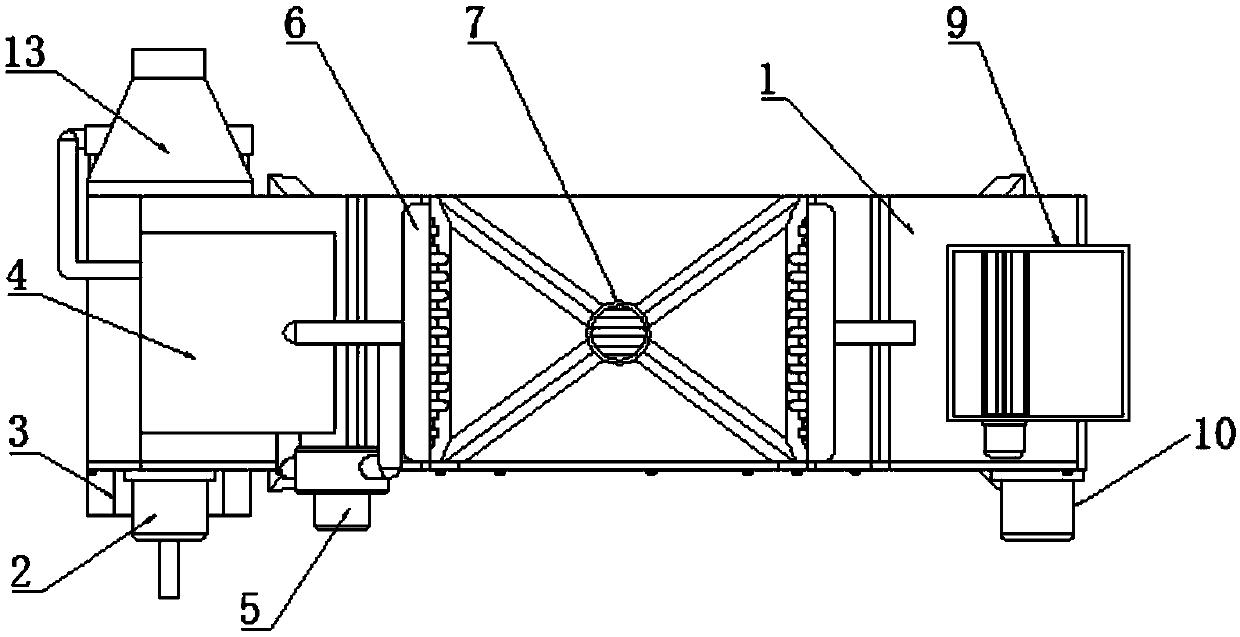

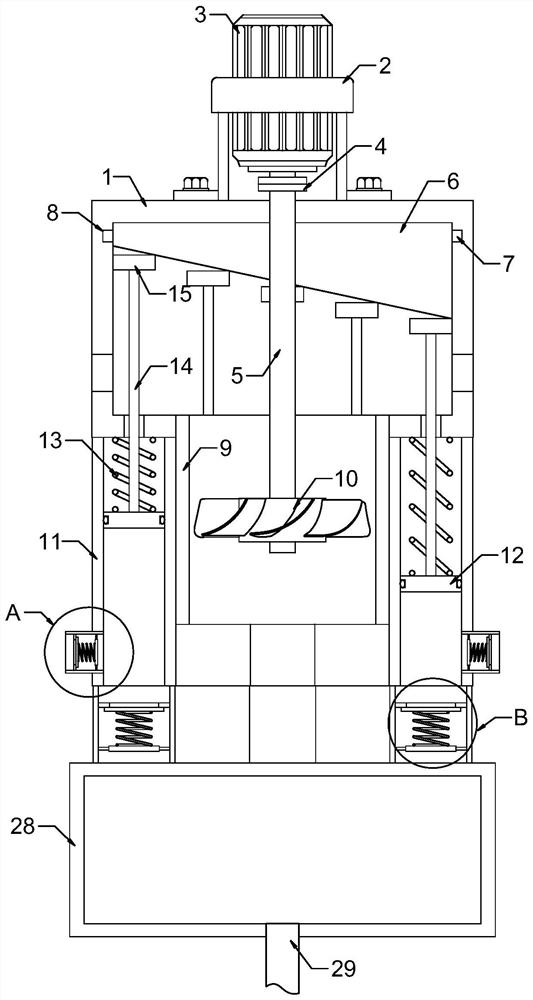

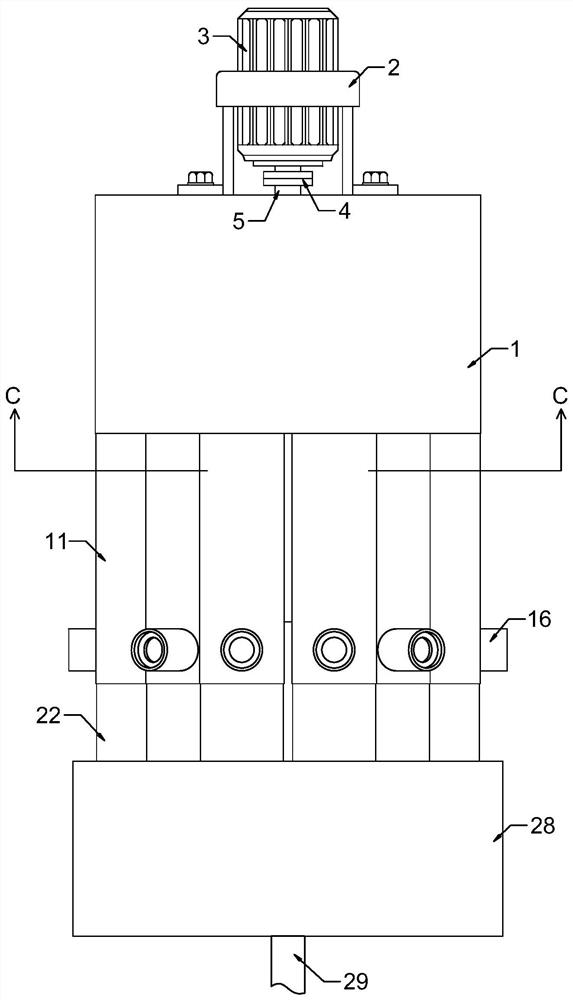

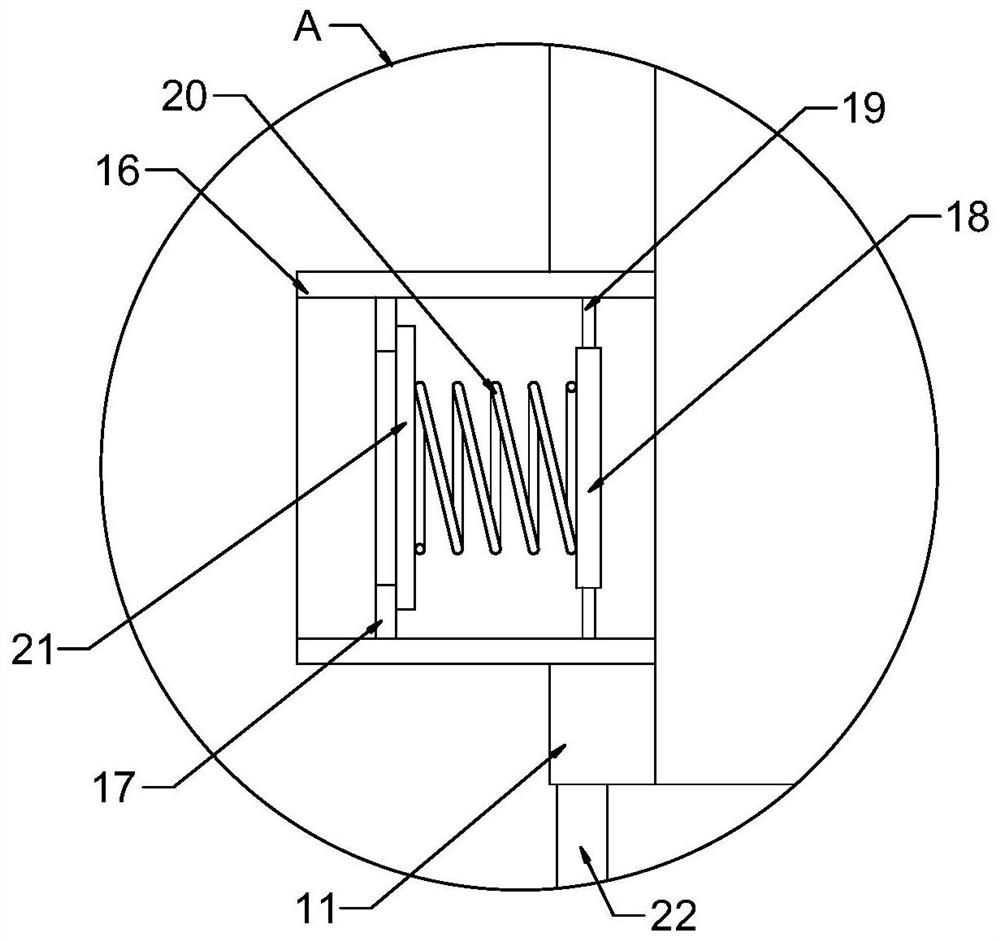

Sludge sufficient combustion processing device

The invention provides a sludge sufficient combustion processing device. The device comprises a furnace body, a hot air generation mechanism, a feeding mechanism, a first air exhaust mechanism, a second air exhaust mechanism and a fire grate; the feeding mechanism comprises a first shell, a second shell, a first rotating shaft and a second rotating shaft; the first rotating shaft is arranged in the first shell, the extending direction of the first rotating shaft is consistent with the extending direction of the first shell, a first spiral blade is arranged on the outer side of the first rotating shaft, and a first channel extending in the axial direction of the first rotating shaft is formed in the inner side of the first rotating shaft; the second rotating shaft is arranged in the second shell, the extending direction of the second rotating shaft is consistent with the extending direction of the second shell, a second spiral blade is arranged on the outer side of the second rotating shaft, a second channel and a first spiral channel extending in the axial direction of the second rotating shaft are arranged in the second rotating shaft, and the first spiral channel is spirally arranged around the second channel; and the fire grate is arranged in a combustion cavity and located below a second discharging opening. The device is simple in structure, good in sludge processing effect and capable of sufficiently utilizing energy, and energy consumption is reduced.

Owner:湖南未名环保科技有限公司

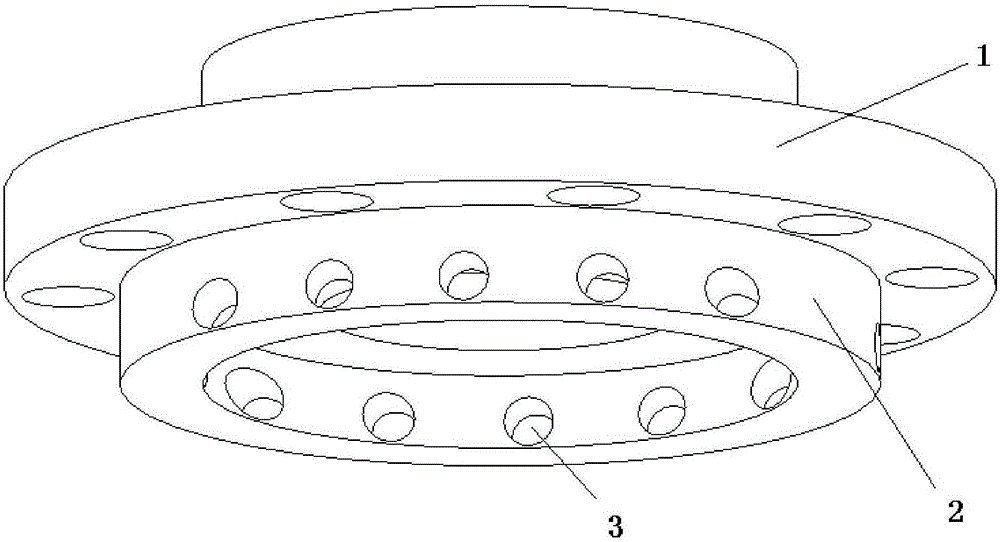

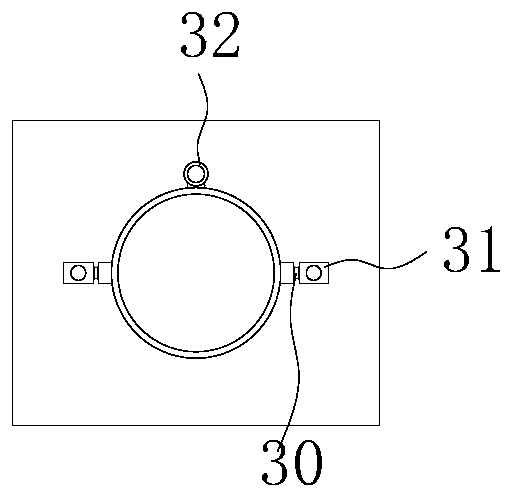

Physiotherapy appliance for traditional Chinese medicine moxibustion

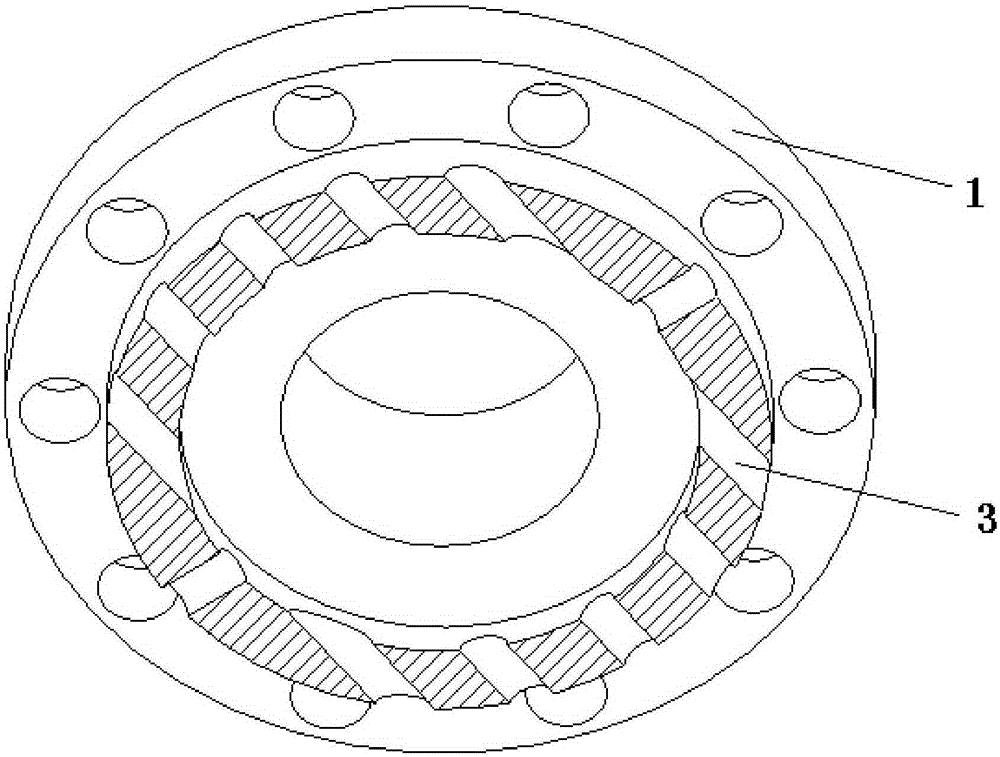

PendingCN113384455AEasy to useReduce labor intensityDevices for heating/cooling reflex pointsPhysical medicine and rehabilitationGear wheel

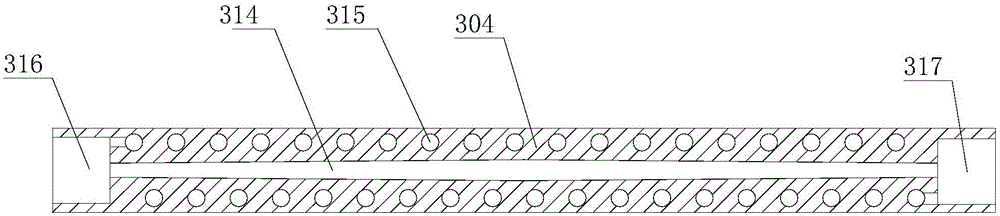

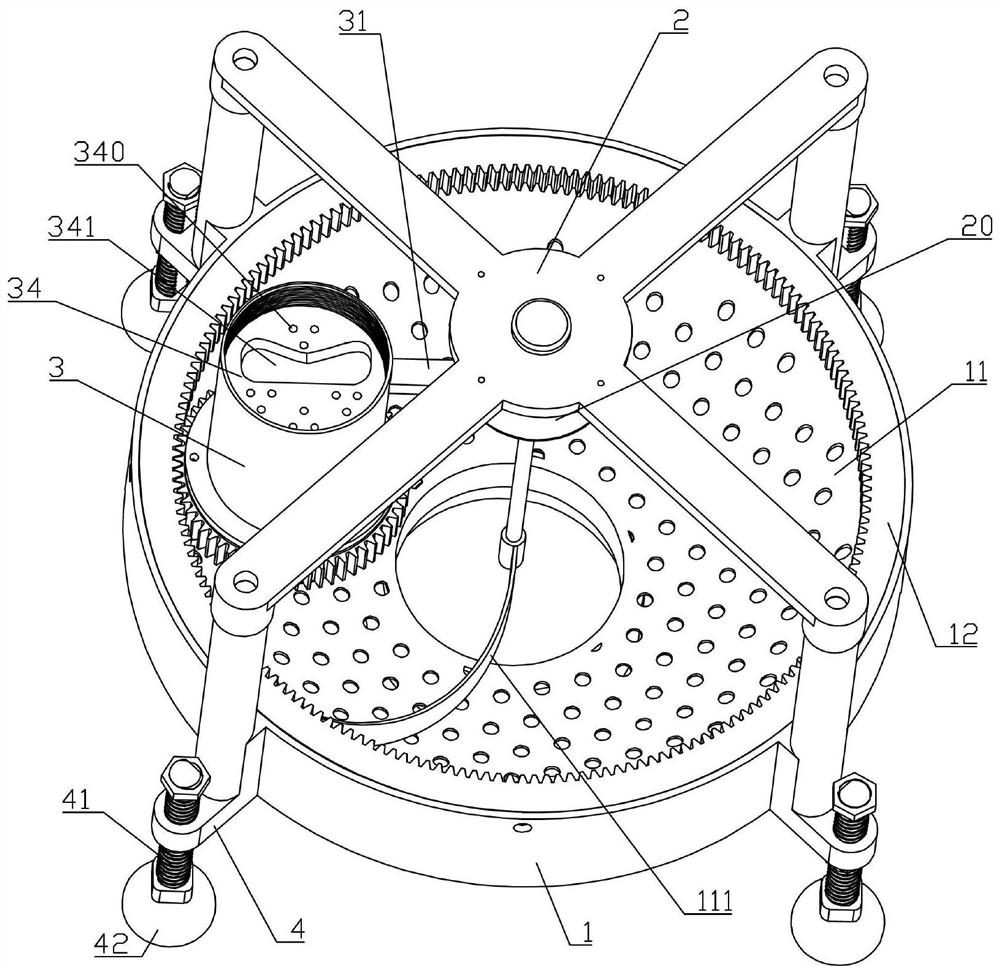

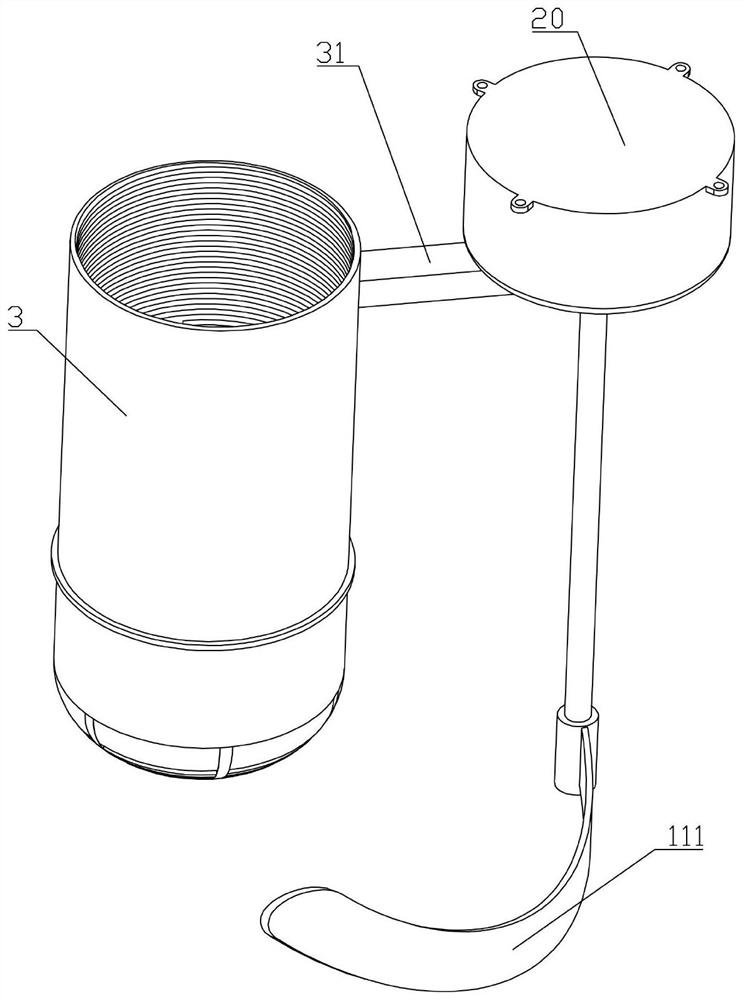

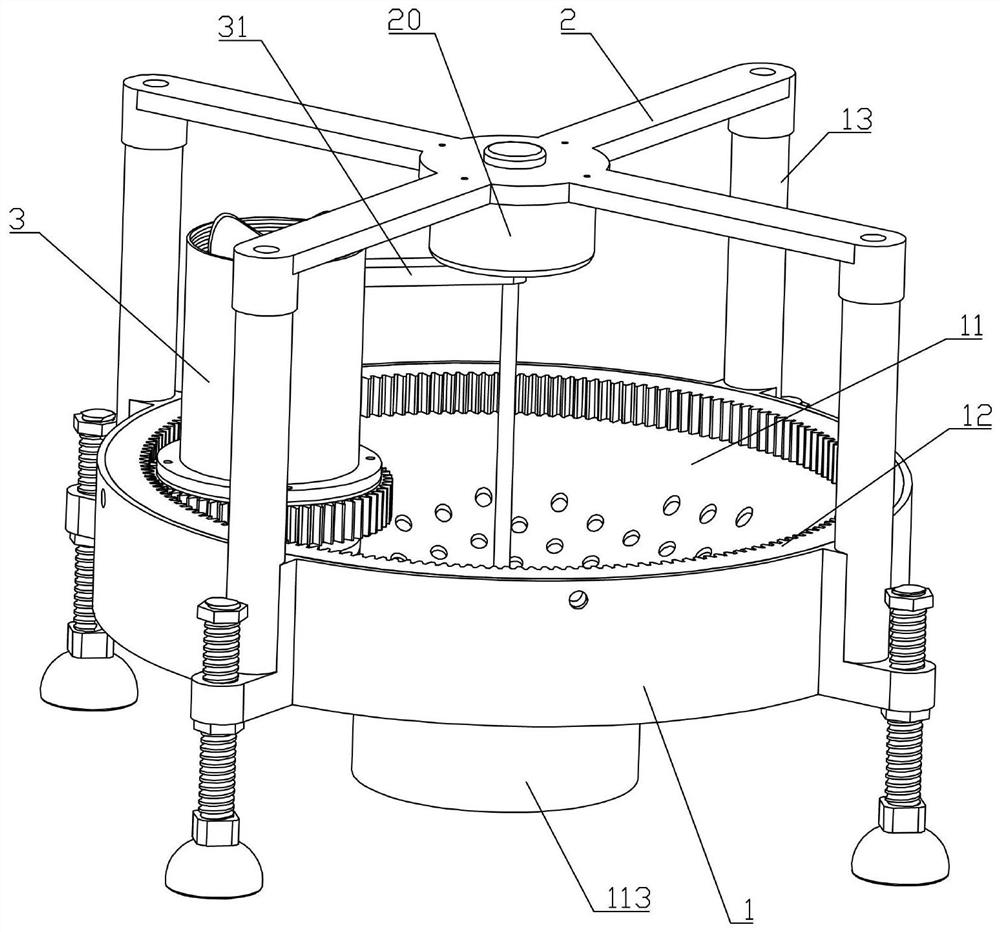

The invention belongs to the technical field of medical instruments, and particularly relates to a physiotherapy appliance for traditional Chinese medicine moxibustion. The physiotherapy appliance for traditional Chinese medicine moxibustion comprises a base and a rotating cylinder for placing moxibustion columns; a shielding net and an inner gear ring are fixedly mounted in the base; a plurality of support columns are fixedly arranged on the base; a mounting seat is mounted on the base through the support columns; a motor is mounted on the mounting seat; a rotating cylinder is of a cylindrical structure with the opened upper end and the closed lower end; the upper portion of the rotating cylinder is in threaded connection with a pressing plate; a compression spring is mounted on the lower end face of the pressing plate; a plurality of first arc-shaped seams are formed on the lower end face of the rotating cylinder; a connecting rod is fixedly mounted at the upper end of the rotating cylinder; the free end of the connecting rod is fixedly connected with an output shaft of the motor; a rotating sleeve is further rotationally mounted at the lower end of the rotating cylinder; a plurality of second arc-shaped seams are formed at the lower end face of the rotating sleeve; a gear is further fixedly mounted on the rotating sleeve; and the gear is meshed with the inner gear ring. The physiotherapy appliance for traditional Chinese medicine moxibustion has the objectives that the moxibustion columns are driven by the motor to rotate so as to complete rotary moxibustion in moxibustion; the physiotherapy appliance is simple to use; and labor intensity is lowered.

Owner:AFFILIATED YONGCHUAN HOSPITAL OF CHONGQING MEDICAL UNIV

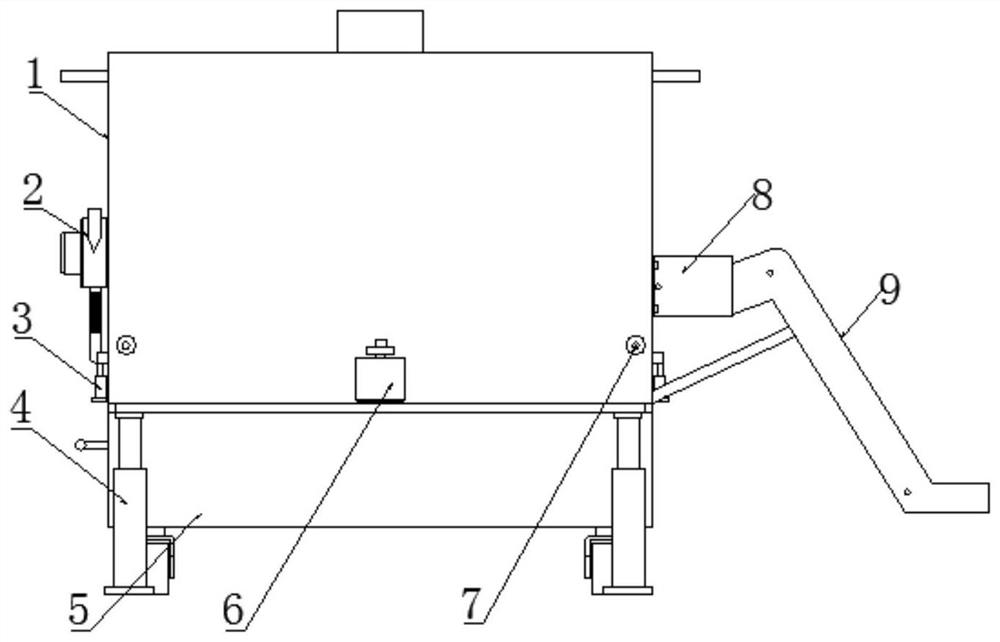

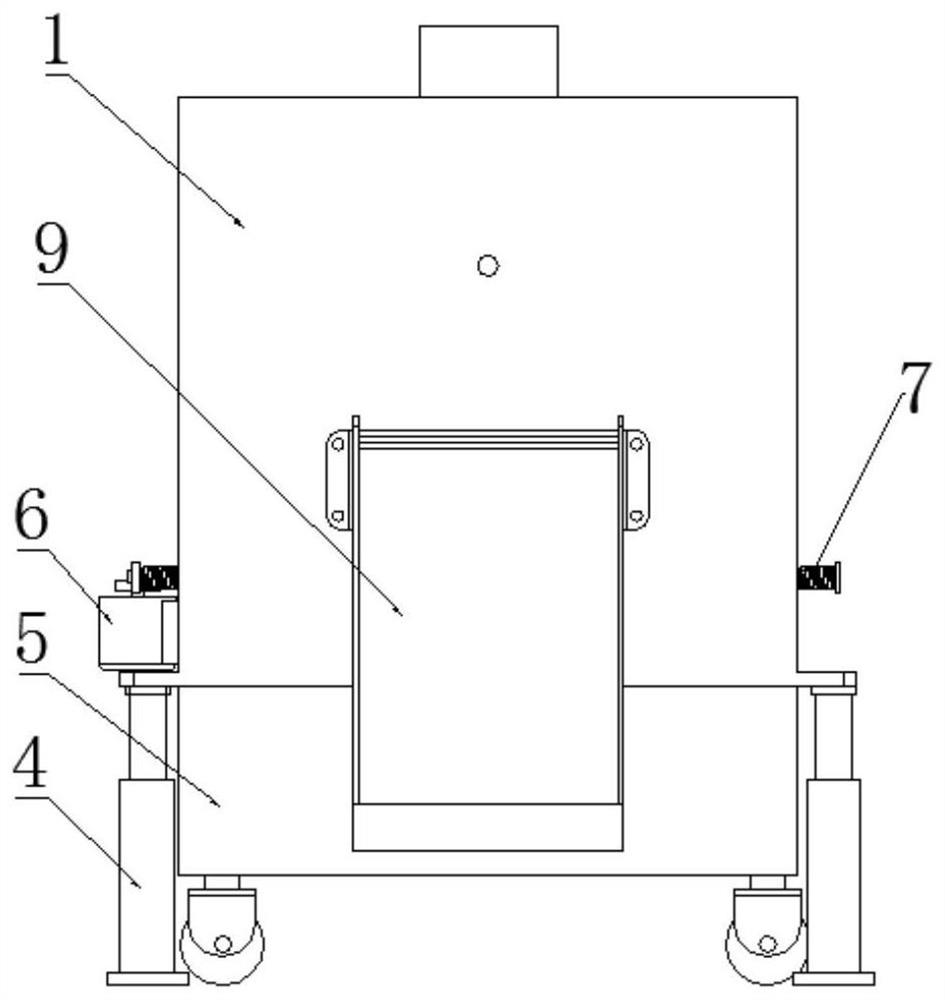

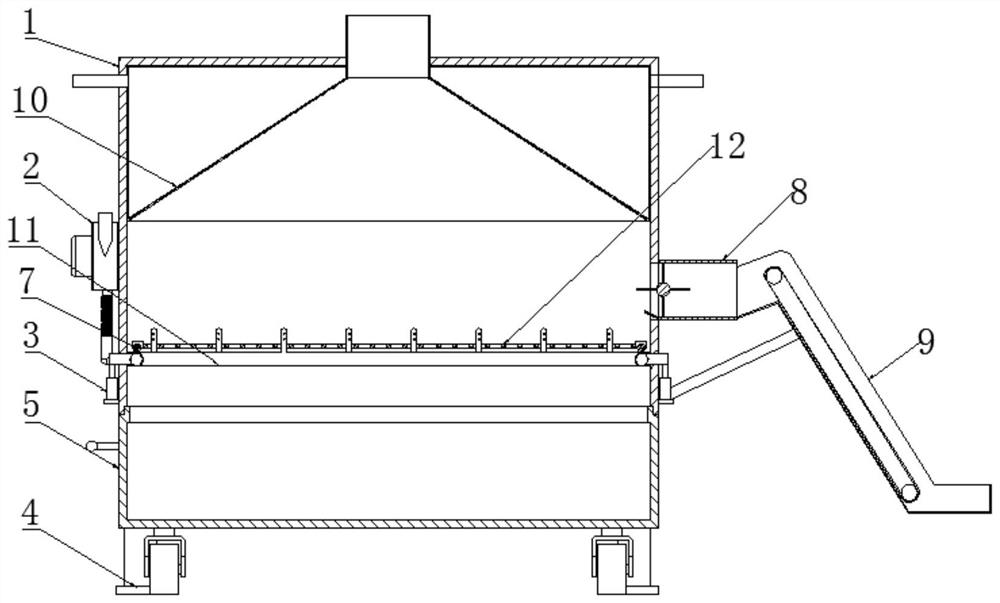

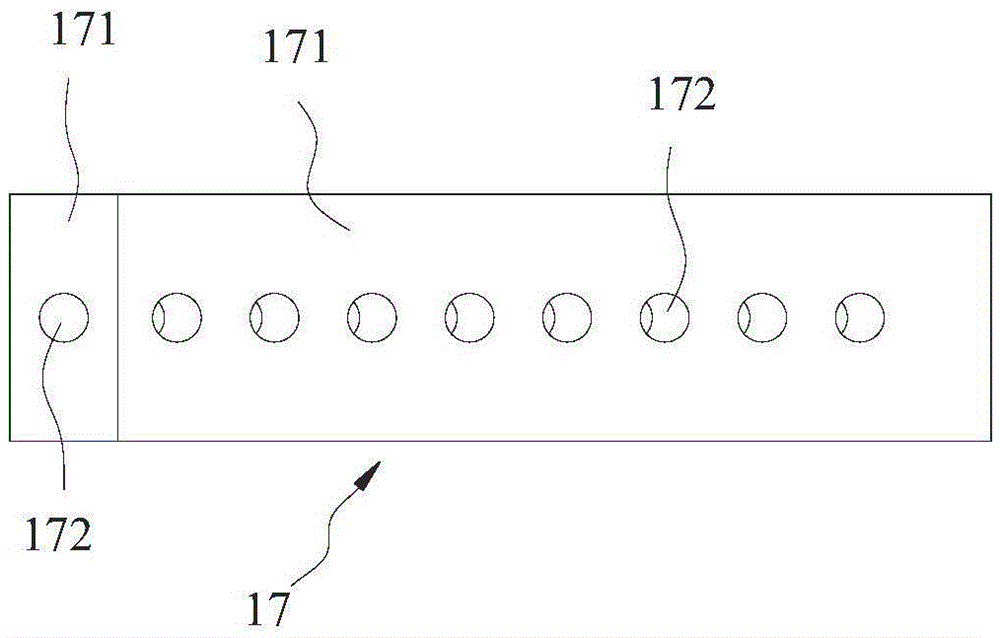

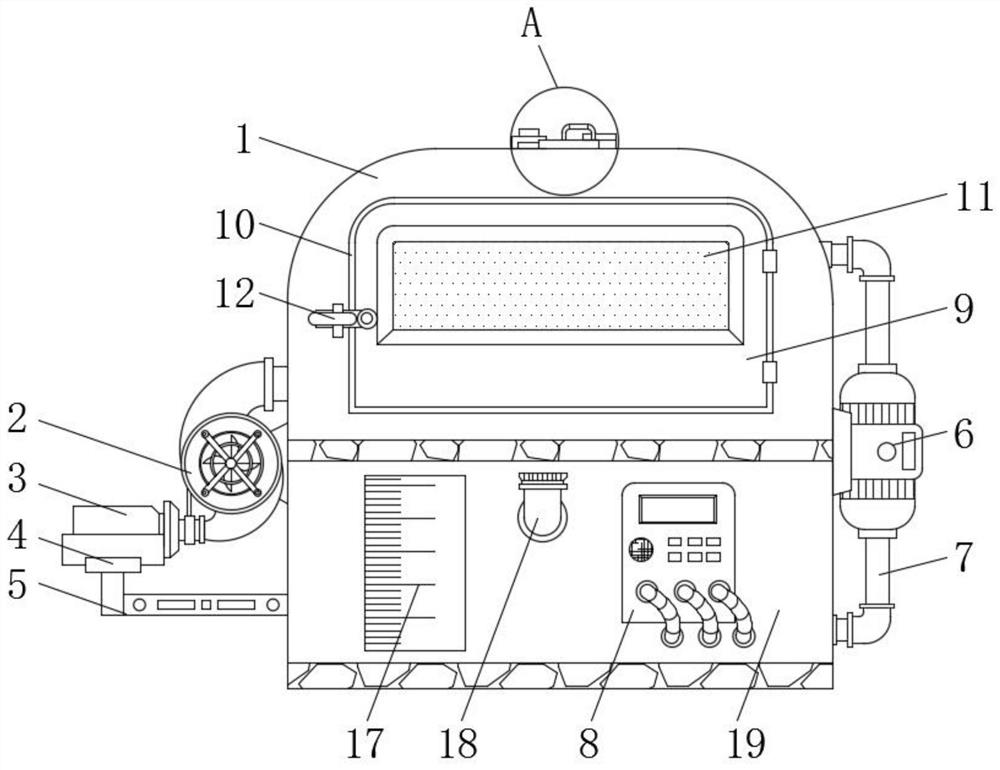

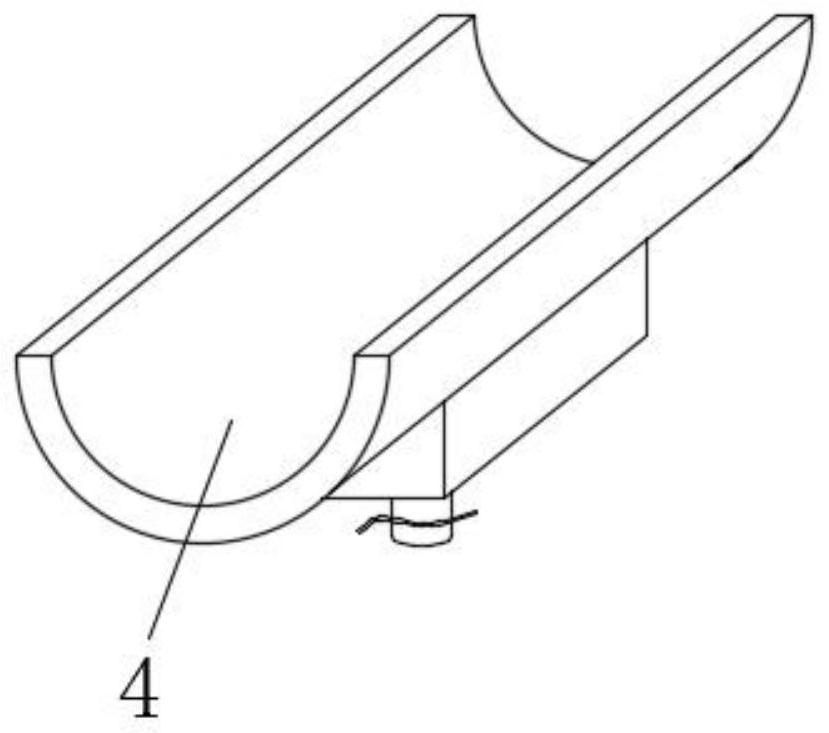

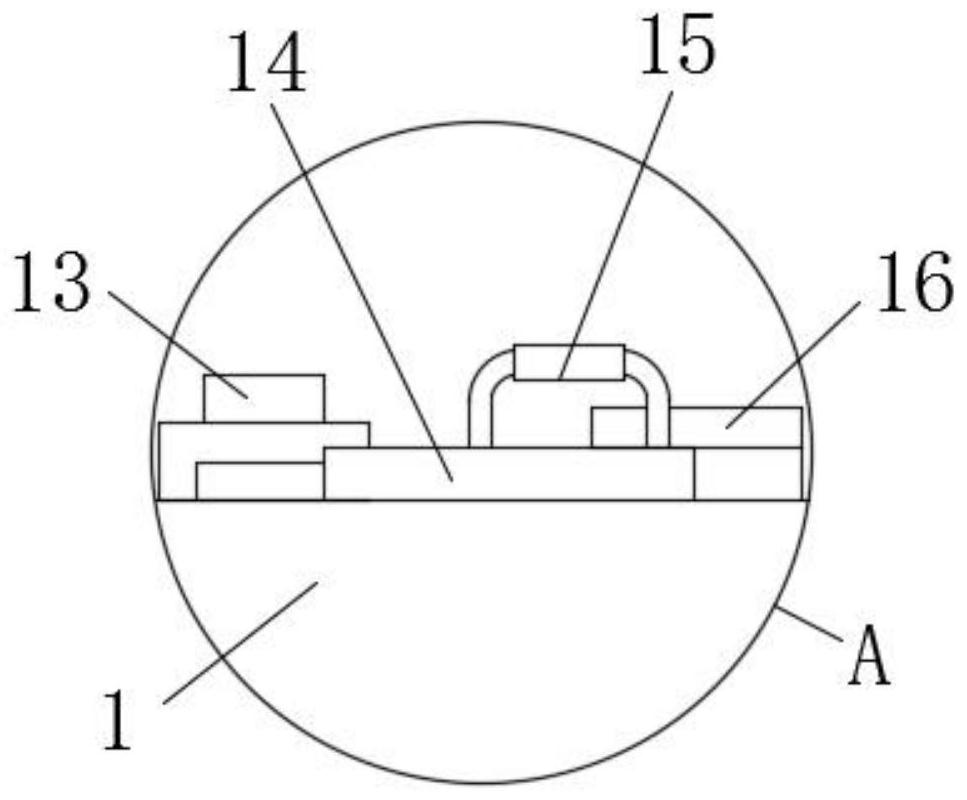

Efficient biomass fuel boiler

InactiveCN112628785AEasy to excludeEasy dump handlingSteam generation using pressureBlast-producing apparatusCombustionProcess engineering

The invention discloses an efficient biomass fuel boiler. The boiler comprises a boiler body, a storage box and a lifting machine, the detachable and movable storage box is arranged at the lower end of the boiler body, the upper end of the storage box is clamped in a lower port of the boiler body, lifting supporting legs are fixedly arranged at the positions, located at the front side and the rear side of the storage box, of the lower end face of the boiler body, and a guide mechanism is arranged on the end face of the boiler body. The lifting machine is arranged at the right end side of the guide mechanism. Fuel is loosened through exhaust column heads on a lifting frame, the fuel combustion efficiency is improved, collected ash can be conveniently poured in a centralized manner through the storage box convenient to separate, and ash discharging and cleaning are more convenient and faster; and meanwhile, the lifting frame blows air through a draught fan in pipeline connection to convey air to the lifting frame, the air is dispersed in the fuel through exhaust holes in the exhaust column heads, oxygen supply for fuel combustion is guaranteed, and the fuel is combusted more sufficiently.

Owner:瑞安市瑞海机电有限公司

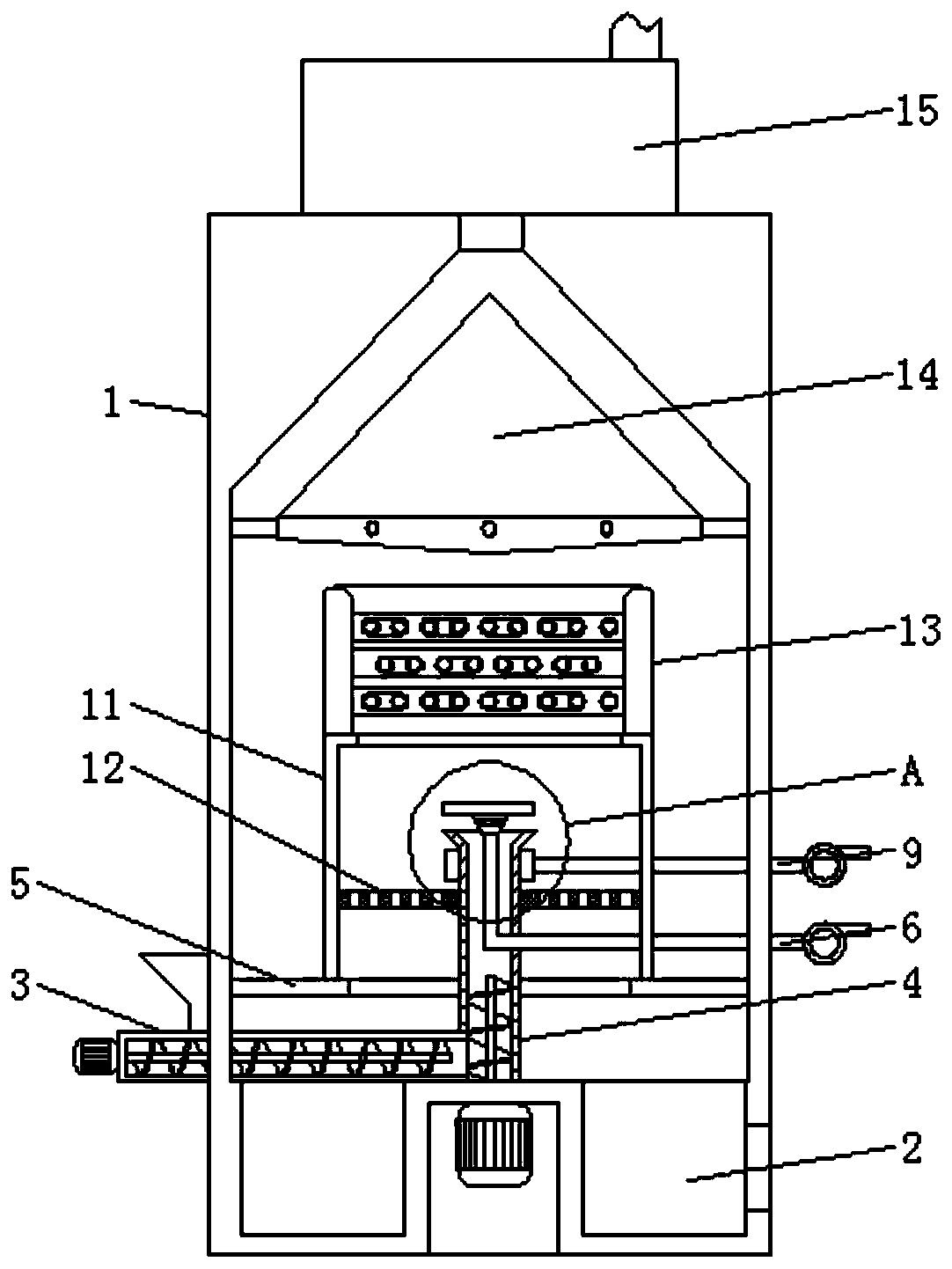

Biomass energy particle gasification combustion boiler

ActiveCN110500576AGuaranteed maximum utilizationIncrease profitSolid fuel combustionIndirect carbon-dioxide mitigationEnergy particleSlag

The invention relates to the field of biomass energy combustion equipment, and discloses a biomass energy particle gasification combustion boiler. The biomass energy particle gasification combustion boiler comprises a boiler body; a slag discharge chamber is formed in the bottom of an inner cavity of the boiler body; a feeding box is arranged at the bottom of the side surface of the boiler body; acharging bin positioned at the external of the boiler body is arranged at the top of the feeding box; and one end of the feeding box extends into the boiler body. In the biomass energy particle gasification combustion boiler, through design of a guide box at the bottom of the combustion boiler, a first ventilation pipe, an exhaust pipe, a second ventilation pipe and an exhaust ring, biomass fuelparticles are fed on a fuel loading plate in the combustion boiler from the top of the guide box; in the period of stopping charging, the exhaust pipe is used for continuously exhausting, so that thefuel combustion is facilitated; and meanwhile, air currents scattered outwards are formed at the top of the guide box, so that the combustion phenomenon cannot be generated at the top and in the guidebox to effectively guarantee the maximal utilization of biomass combustion particles.

Owner:赣州佳广智能装备科技有限公司

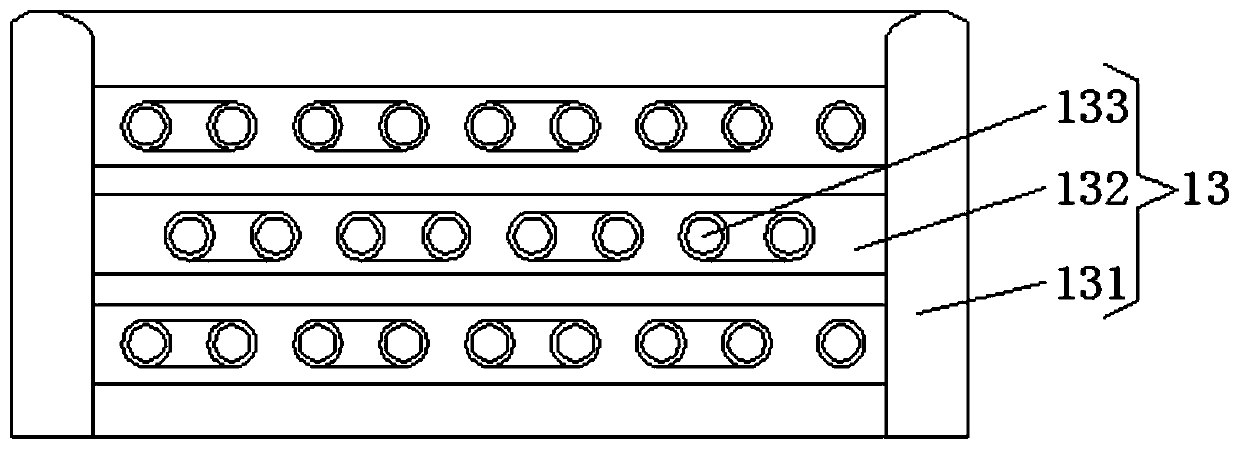

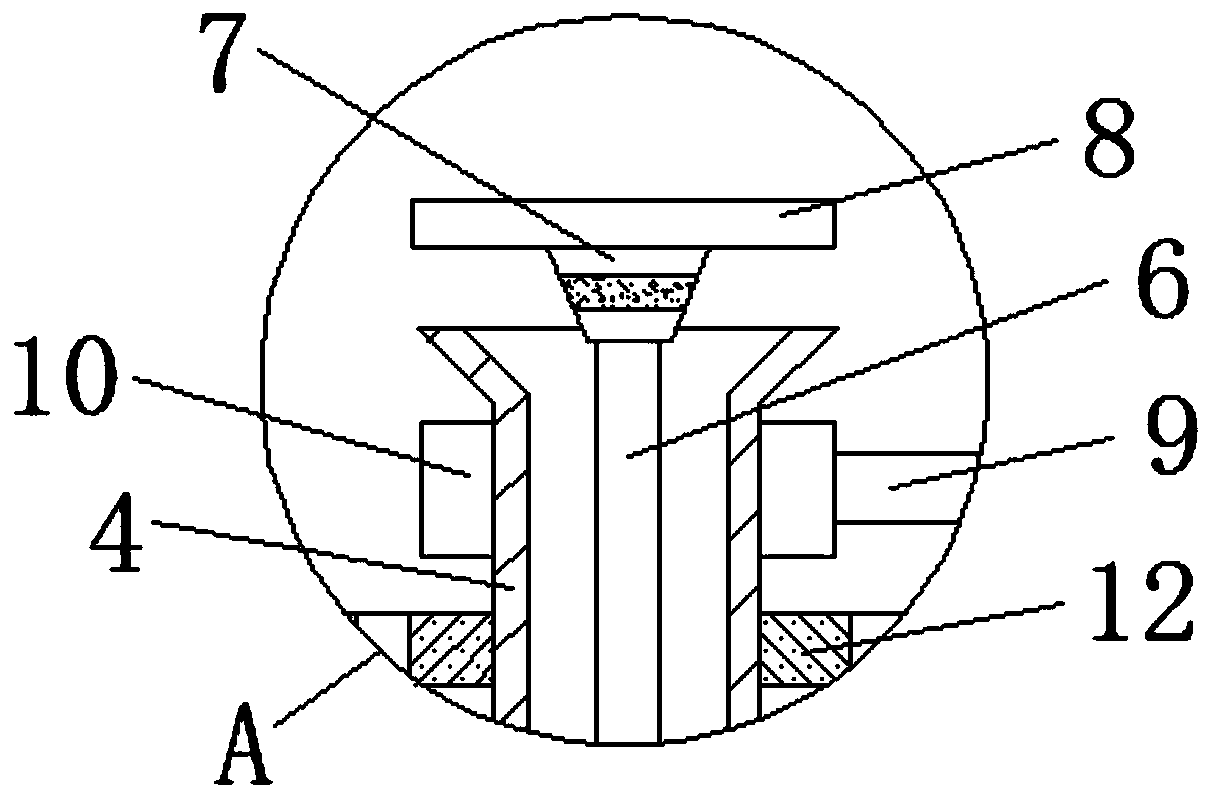

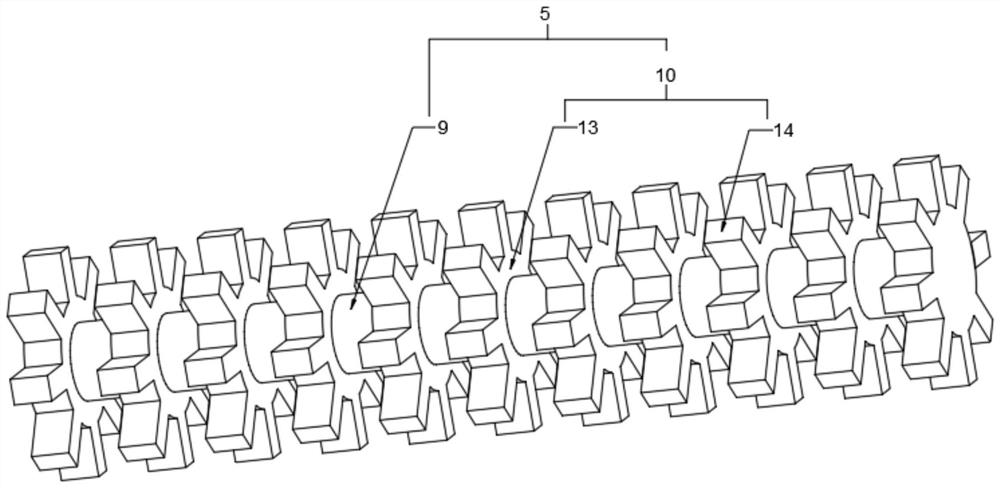

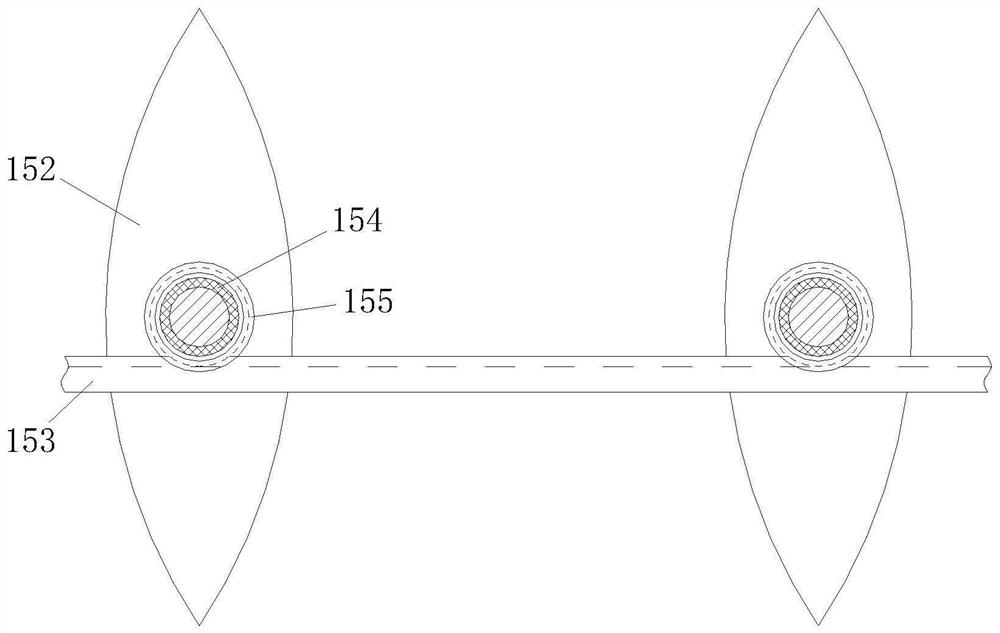

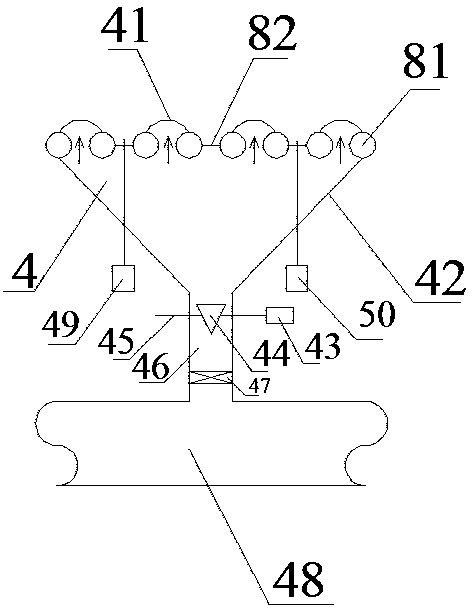

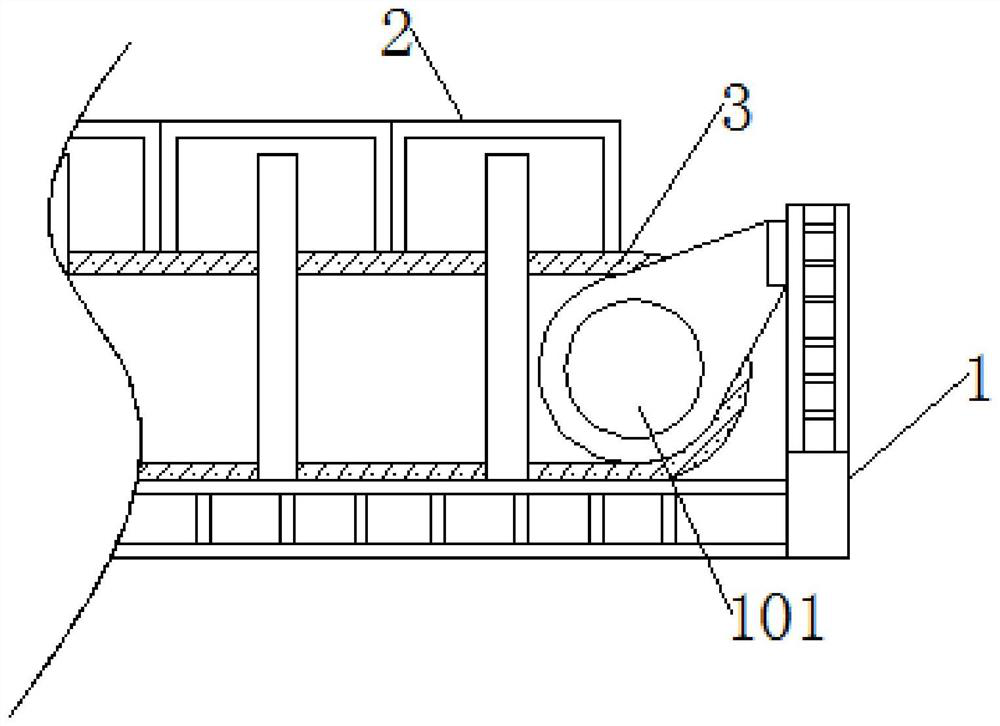

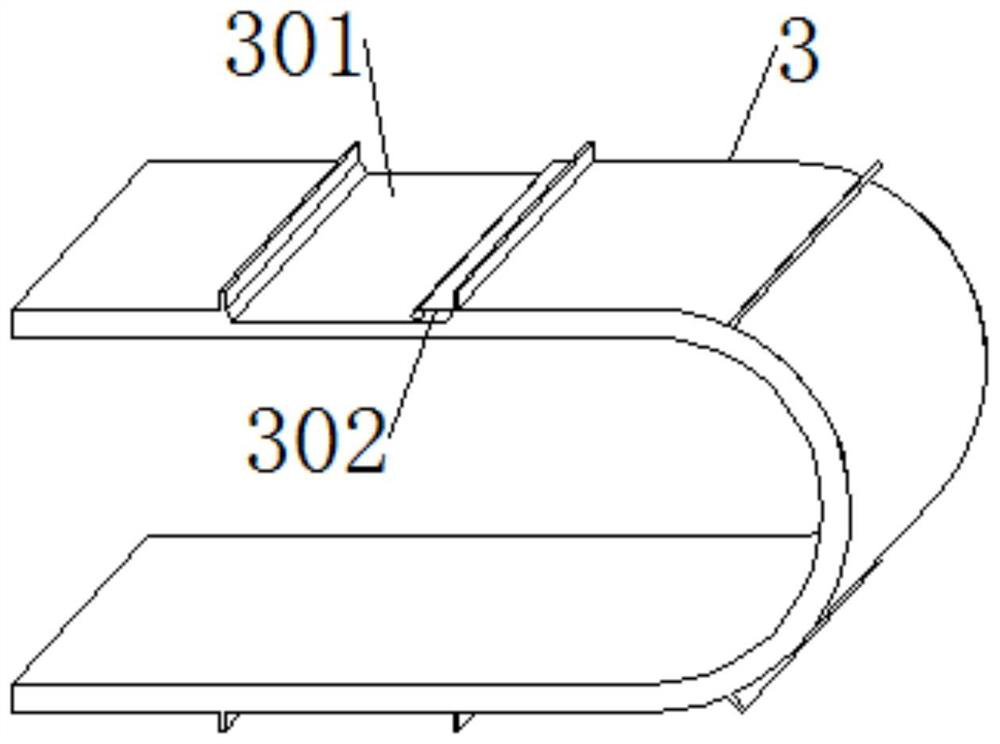

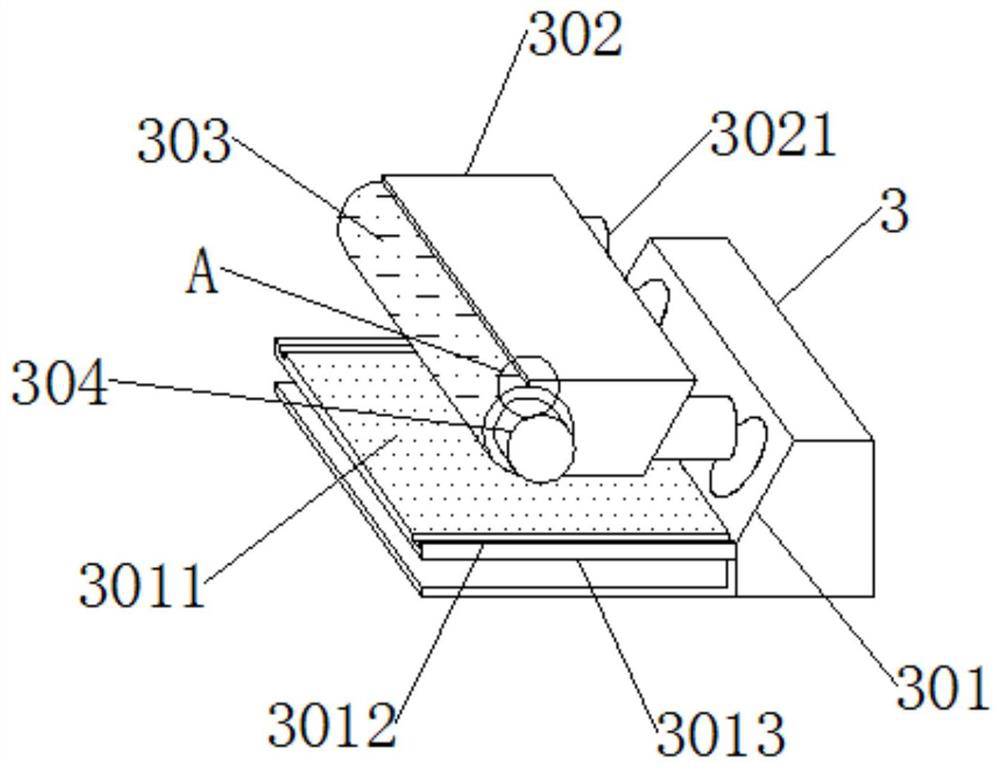

Anti-slagging incinerator with rotary blade fire grate

ActiveCN114484451ASmooth ventilation and oxygen intakeBurning effectIncinerator apparatusNon-combustible gases/liquids supplySlagEnvironmental geology

The anti-slagging incinerator comprises an incinerator body and a blade type grate furnace obliquely arranged in the incinerator body, the blade type grate furnace comprises a grate frame, and a plurality of first grate mechanisms and a plurality of second grate mechanisms are arranged on the grate frame; the first fire grate mechanism and the second fire grate mechanism are arranged in a staggered mode, an inclined material conveying channel is formed between the first fire grate mechanism and the second fire grate mechanism, and the material conveying channel is in an inclined shape with the high feeding end and the low discharging end. The first fire grate mechanism is connected with a driving device, and the driving device is used for enabling the first fire grate mechanism and the second fire grate mechanism to rotate in the same direction for material transmission; and the driving device is used for enabling the rotating directions of the first fire grate mechanism and the second fire grate mechanism to be opposite for slag crushing. The blade type fire grate is adopted for garbage conveying operation and slag crushing operation, combustion materials can be effectively prevented from hardening and slagging on the fire grate, smooth ventilation and oxygen feeding are guaranteed, and garbage combustion is not affected.

Owner:四川天源人科技有限公司

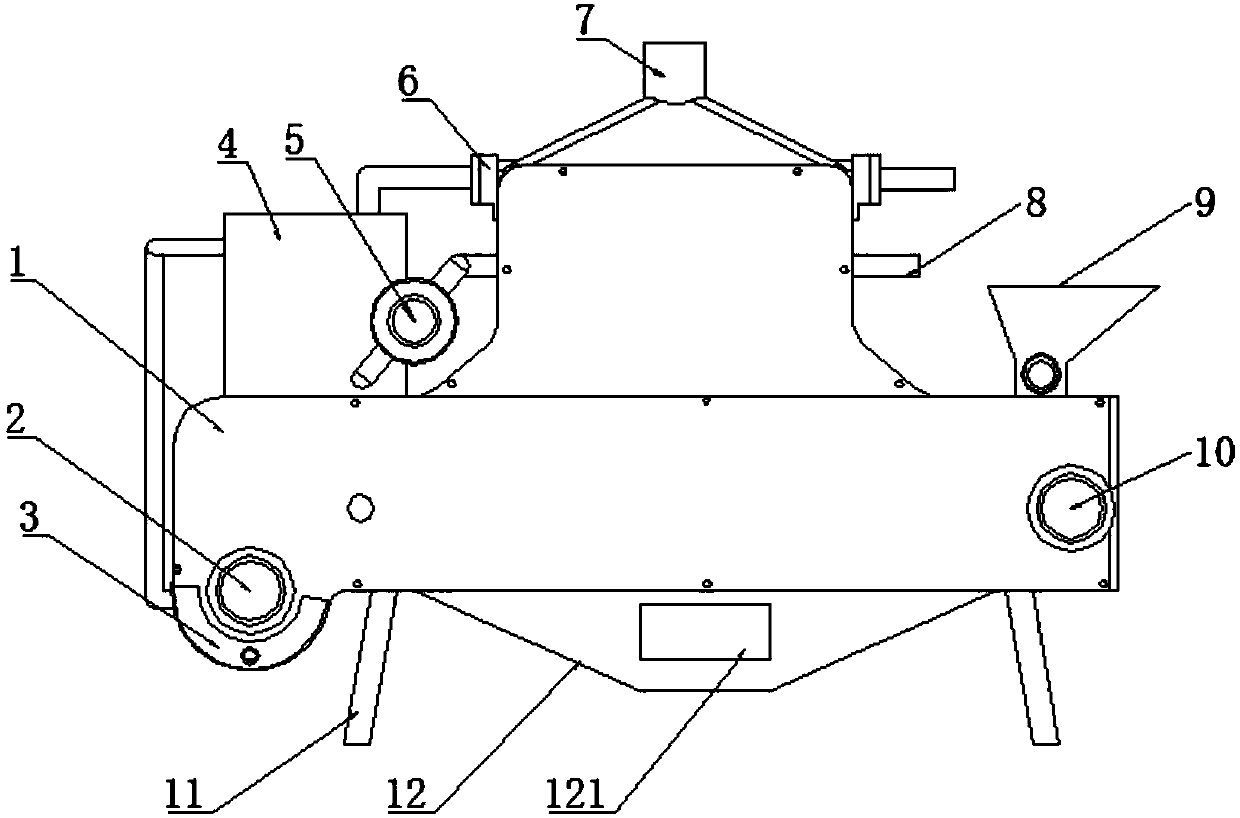

Efficient biomass fuel steam boiler

InactiveCN109539238AIncrease contact areaBurn fullySolid fuel combustionSteam boilersCombustorBiofuel

The invention discloses an efficient biomass fuel steam boiler. The efficient biomass fuel steam boiler comprises a boiler body, a furnace pipe and a conveyer belt. The boiler body is composed of a box and a shell. The shell is fixedly arranged to the middle of the upper end face of the box. The shell communicates with an inner chamber of the box. The transverse furnace pipe is arranged on the inner side of the shell. A smoke exhaust pipe is arranged at the upper end of the shell. According to the efficient biomass fuel steam boiler, because the stainless steel conveyer belt is arranged for implementing conveying of the biomass fuel to the bottom of the furnace pipe, a combustor ignites the biomass fuel to achieve fluid type combustion, and it is avoided that biomass fuel cannot burn sufficiently because of being piled up when burning; and because a material stirring rod arranged in a hopper continuously rotates to evenly spread the biomass fuel in the hopper on the stainless steel mesh conveyer belt, the contact area between the biomass fuel and the air is enlarged, more sufficient combustion is achieved, and the phenomenon that because of insufficient combustion, a large quantityof polluting gas is generated and pollutes the air.

Owner:苏大伟

Smelting furnace for aluminum ingot processing with exhaust gas purification function

InactiveCN110906750ABurn fullyAvoid uneven burningIncreasing energy efficiencyIncrustation removal devicesEngineeringThreaded rod

The invention discloses a smelting furnace for aluminum ingot processing with an exhaust gas purification function, and relates to the technical field of exhaust gas purification. The smelting furnacecomprises a base, supporting legs are welded to the bottom of the base, the top of the base is welded and mounted on a box body, the box body is internally provided with a first partition plate and asecond partition plate, the first partition plate and the second partition plate sequentially divide the interior of the box body is divided into a lifting bin, a combustion bin and a residue bin, afixed block is welded to the top of the lifting bin, vertical threaded rods and a transverse threaded rod are arranged in the fixed block, the number of the vertical threaded rods is two groups and the two groups of vertical threaded rods are arranged in parallel. According to the smelting furnace, through cooperative use of a dust falling bin, an atomizer, a water inlet pipe, a water tank, a submersible pump, a filtering device and a filtering plate, the device has the function of filtering the exhaust gas, so that the waste gas generated in the process of smelting the aluminum ingot is not directly discharged into the atmosphere, and the device is more environmentally friendly and green to a certain extent.

Owner:湖州好灵通铝业有限公司

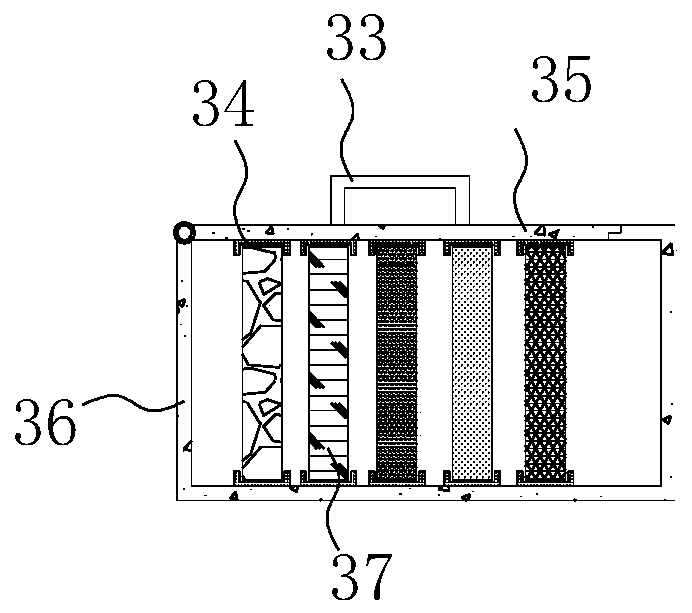

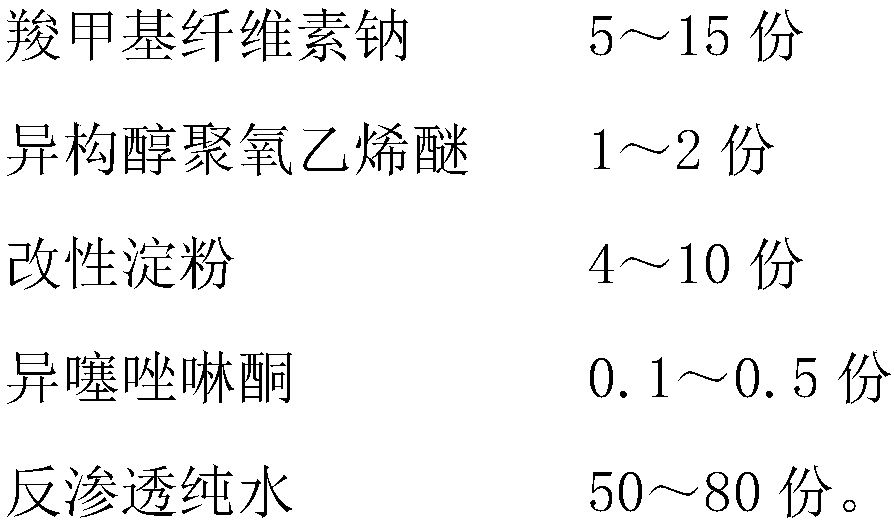

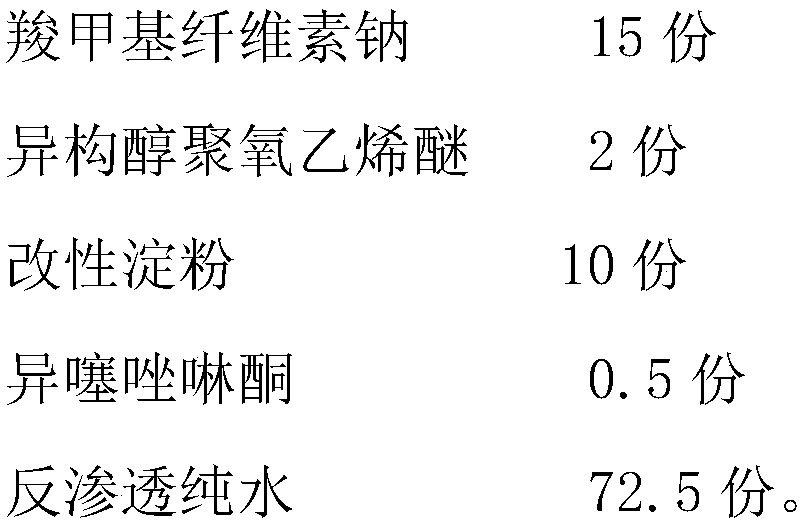

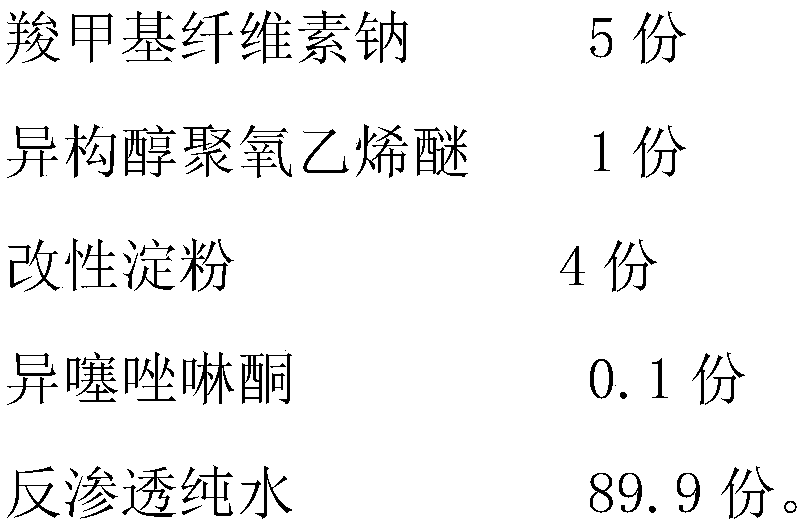

Coal pile dustproofing agent

The invention discloses a coal pile dustproofing agent. The coal pile dustproofing agent has a composition shown in the description in the weight percentage ratio. The coal pile dustproofing agent isuniformly sprayed to the surface of a coal pile through a mobile spray device according to a ratio of 90-180g / m<2>. The coal pile dustproofing agent has strong adhesiveness, can well seal the coal seam, can prevent dust scattering, realizes a low cost, does not adversely affect the combustion of coal, prevents pollution caused by combustion and can be used for storage and transportation of variouscoal piles.

Owner:田景潭

Solid waste treatment equipment for environmental protection engineering

PendingCN113587106ABurn fullyBurning effectBlast-producing apparatusIncinerator apparatusEnvironmental engineeringWaste treatment

The invention is applicable to the field of environmental protection engineering, and provides solid waste treatment equipment for environmental protection engineering. The solid waste treatment equipment comprises a support plate and a combustion box fixedly mounted on the support plate, and further comprises a solid waste refining mechanism mounted on the combustion box and comprising a grinding assembly and a first driving assembly used for driving the grinding assembly to crush solid waste, and a solid waste treatment mechanism installed on the combustion box; and the solid waste treatment mechanism comprises a second driving assembly, a vibration assembly, a combustion assembly and a material returning assembly, and the combustion assembly is used for combusting refined solid waste. The first driving assembly is used for driving the grinding assembly to conduct refining treatment to the solid waste, and sufficient combustion is facilitated; the refined solid waste falls on the vibration assembly, and the second driving assembly is used for driving the vibration assembly to drive the solid waste to vibrate up and down; and thus, the solid waste can be fully burnt through the combustion assembly, and waste residues obtained after combustion fall onto the bottom of the combustion box through vibration.

Owner:林蔚斌

Heating stove with blind

InactiveCN106322493AImprove combustion efficiencyIncrease heatCombustion apparatusCentral heating systemCombustion chamberIntegrated design

A heating stove with a blind comprises a stove body. A hollow interlayer is arranged in the wall of the stove body. The blind is arranged on the outer surface of the wall of the stove body. The hollow interlayer communicates with the outer portion of the stove body through the blind. A combustion chamber is arranged in the stove body. The hollow interlayer communicates with the combustion chamber through air inlet pipes. The heating stove with the blind has the beneficial effects that through the integrated design of the blind and the heating stove, the heat dissipation efficiency of the stove wall of the heating stove is improved, an opening of the blind communicates with the interior of the stove, secondary air supply is achieved, and the efficiency of combustion in the stove is improved.

Owner:YICHANG WANGYAN FURNACE IND CO LTD

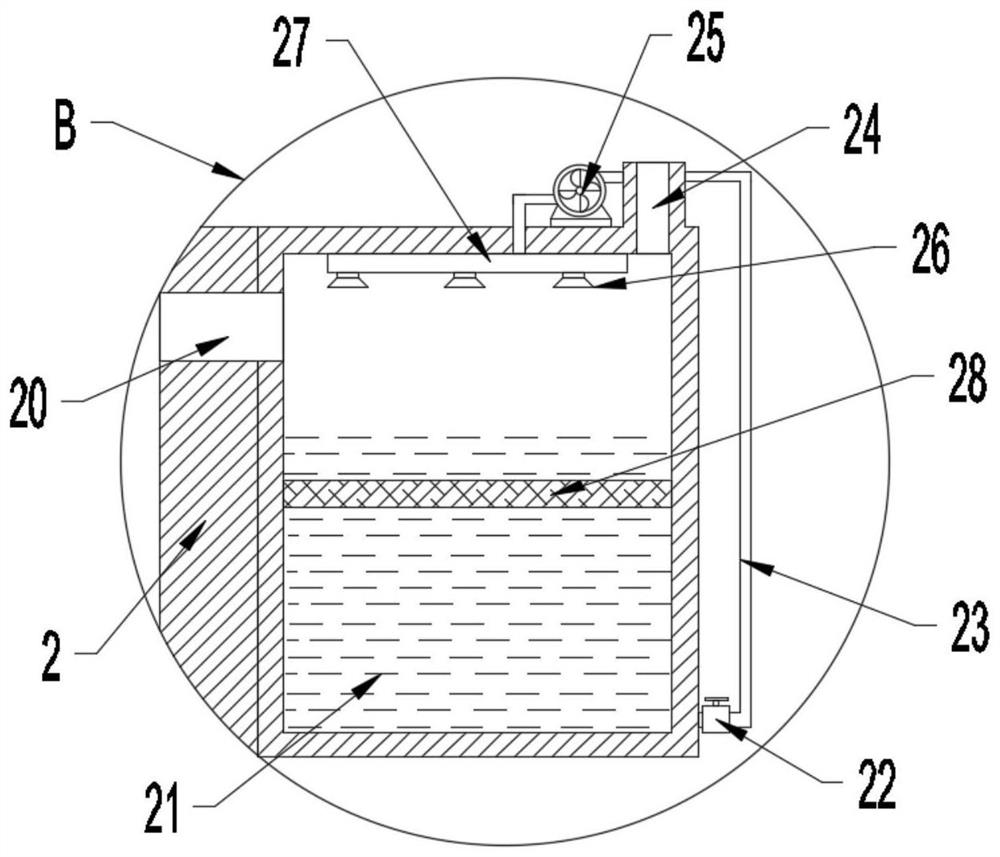

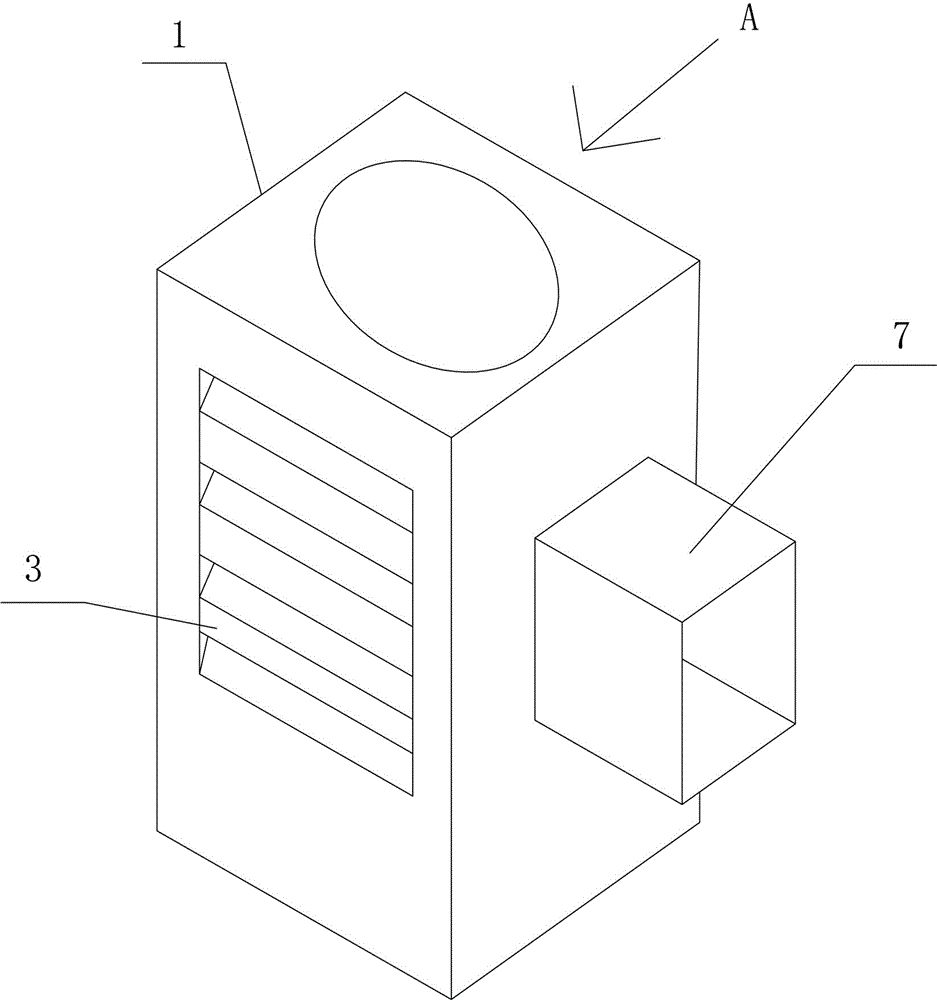

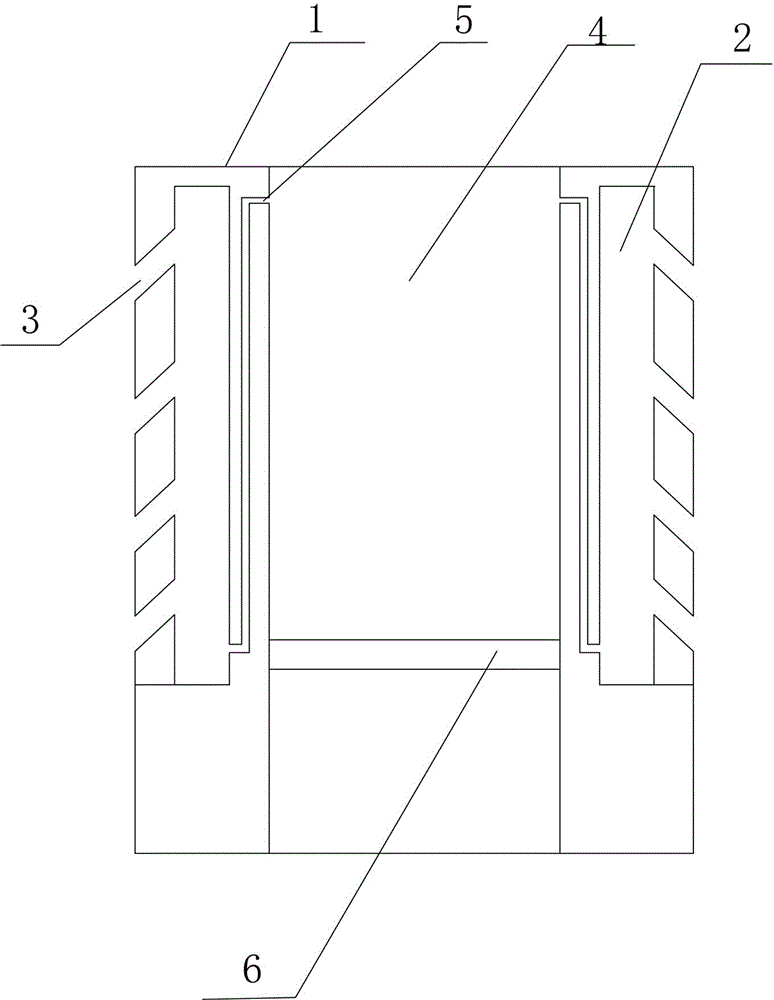

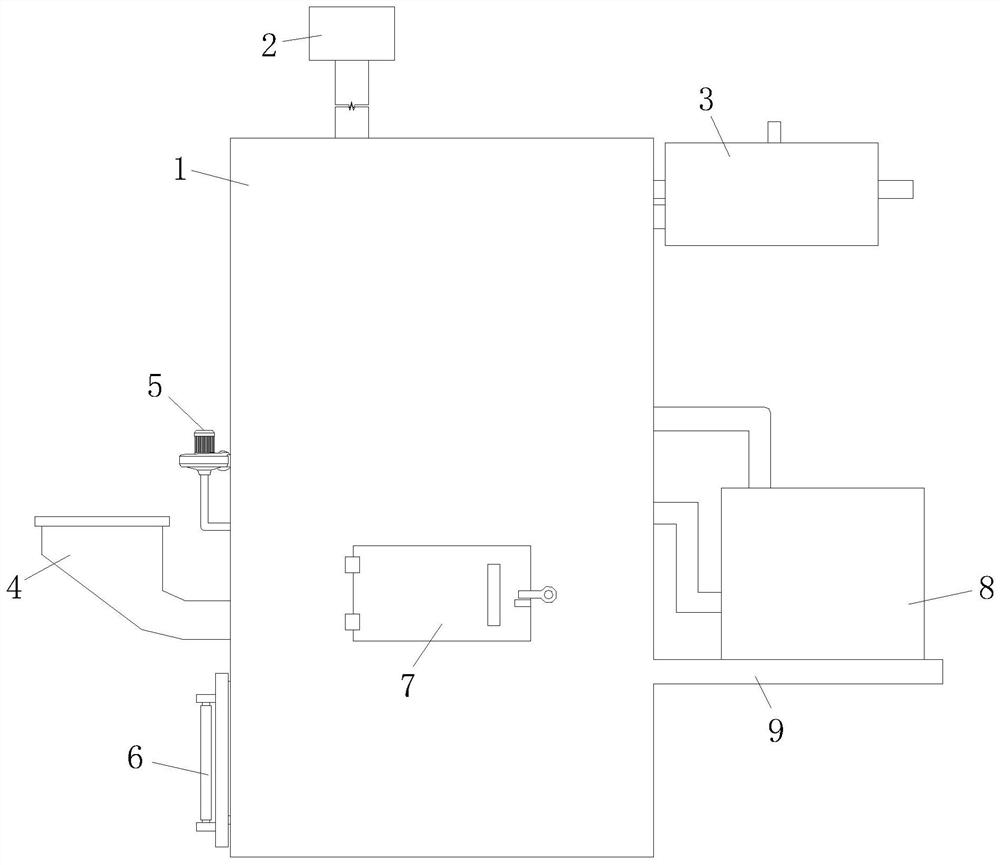

Municipal solid waste incineration power generation system

InactiveCN111828986AAvoid cleaning hassleBurning effectSteam engine plantsIncinerator apparatusWater storageCombustion chamber

The invention belongs to the technical field of waste incineration power generation, and particularly relates to a municipal solid waste incineration power generation system. The municipal solid wasteincineration power generation system comprises a shell, power generation equipment, a feeding hopper and a secondary combustion chamber, wherein the inner side of the shell is divided into a water storage cavity, a primary combustion chamber and a collection cavity through a heat conduction plate and a grating plate from top to bottom, the power generation equipment is arranged on the left side of a water inlet, and the feeding hopper is arranged at the side end of the shell and communicates with the inner side of the primary combustion chamber. According to the municipal solid waste incineration power generation system, smoke dust generated after combustion is subjected to secondary combustion through the arranged secondary combustion chamber, then heat of secondary combustion is introduced into a heat conduction pipe wound around the side wall of the water storage cavity for heating again, so that the heating efficiency is high, and meanwhile, smoke gas emission is reduced; and a heating cavity and an S-shaped pipe are arranged, so that the heat in the heat conduction pipe enters the primary heating cavity to perform primary heating on water flowing in the S-shaped pipe, waste heat utilization is achieved, and meanwhile the time for the water to reach the boiling point after entering the water storage cavity can be shortened.

Owner:管凯迎

Intelligent Water Wall High Temperature Corrosion Prevention System and Method Applicable to Large Power Plant Boilers

The invention relates to an intelligent water wall high temperature corrosion preventing system suitable for a large power station boiler and a method. The system can be adjusted in real time according to the change of the operating conditions of the boiler to prevent a water wall from high temperature corrosion, operating personnel involvement is not needed, and the high temperature corrosion is intelligently prevented. The system comprises a pressurizing pipeline communicated with an air pre-heater outlet hot secondary air box, a booster fan is arranged on the pressurizing pipeline and is communicated with an annular air box of surrounding a protection wall, the annular air box is communicated with branch air boxes through connecting air boxes, and the branch air boxes are communicated with ventilation grooves in the boiler wall. An air flow adjusting device is arranged on the pressurizing pipeline, and the air flow adjusting device comprises an isolation baffle, a master adjusting baffle, an air flow measuring device and a pressure sensor and further comprises a branch adjusting baffle of the connecting air boxes. An intelligent control system adjusts the opening and closing degree of each baffle in the air flow adjusting device according to the operating state of the boiler, and the air flow is controlled to prevent the water wall from the high temperature corrosion.

Owner:STATE GRID CORP OF CHINA +1

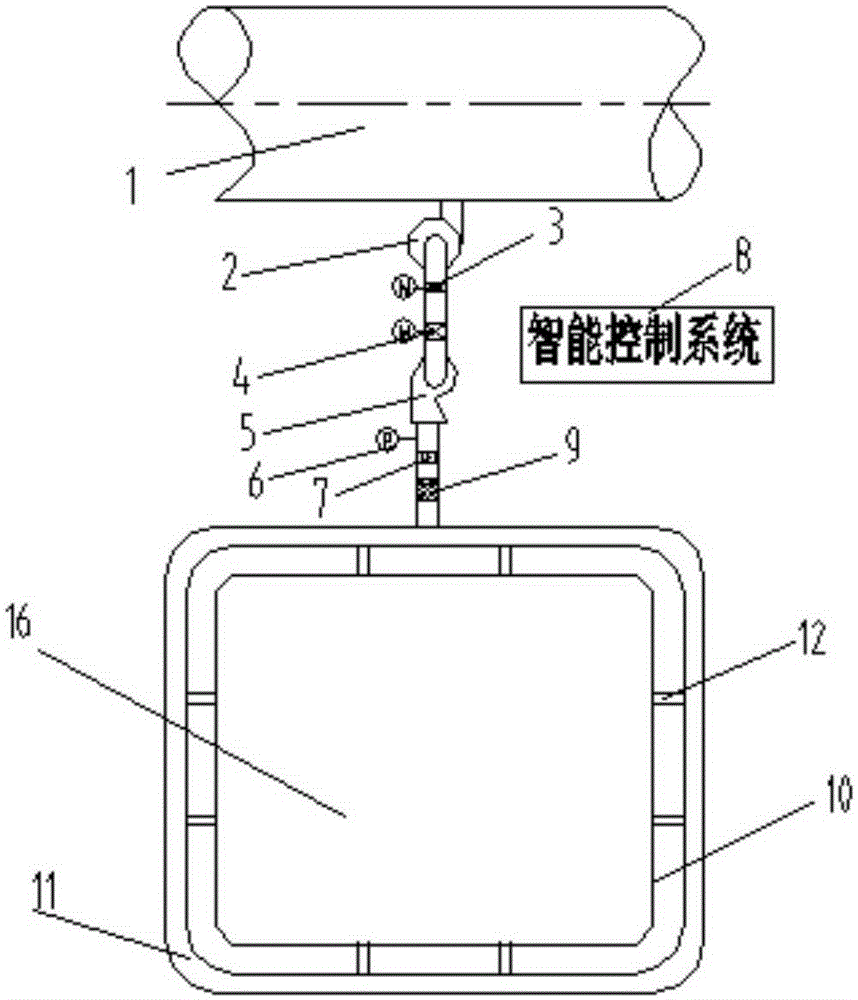

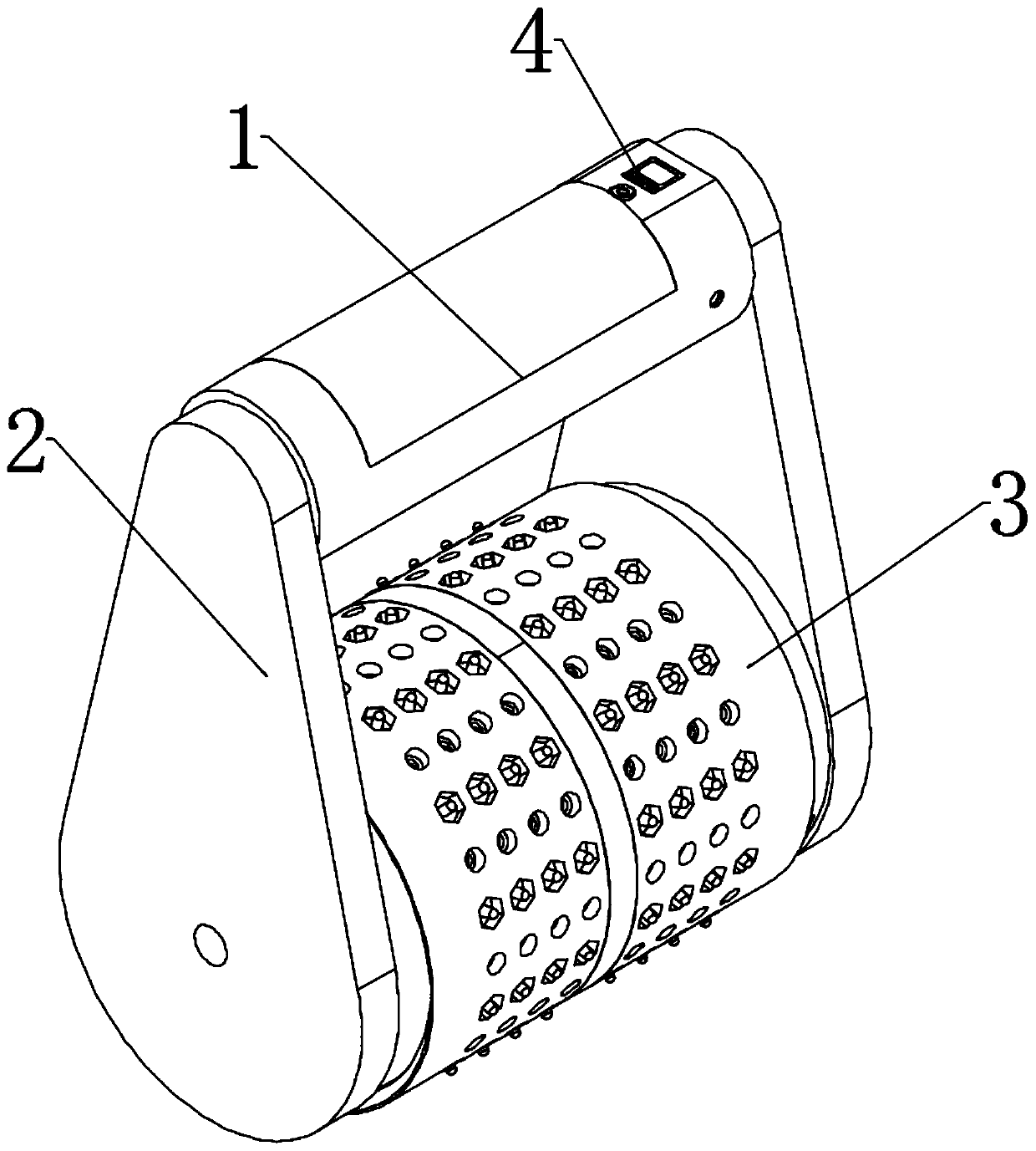

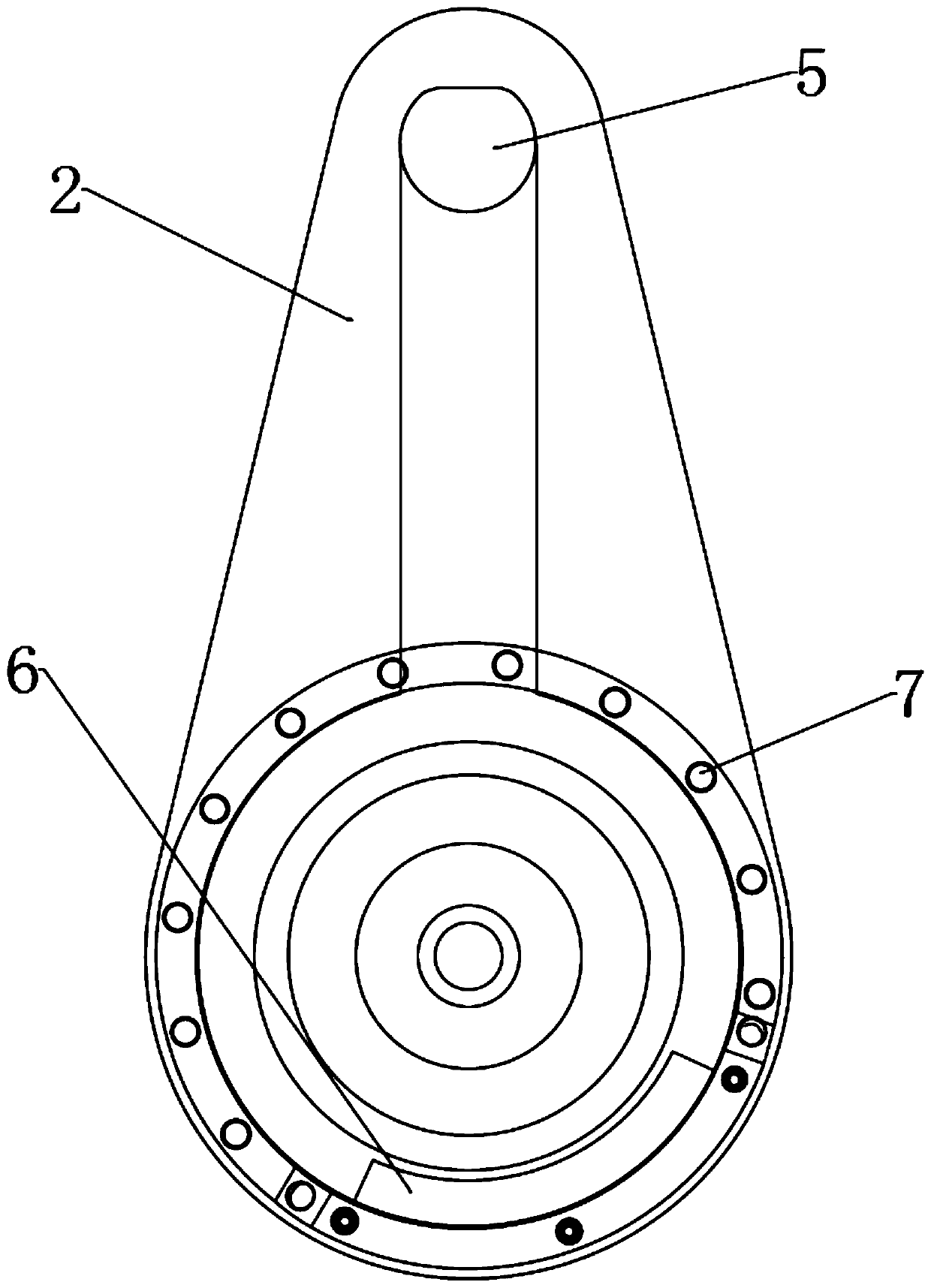

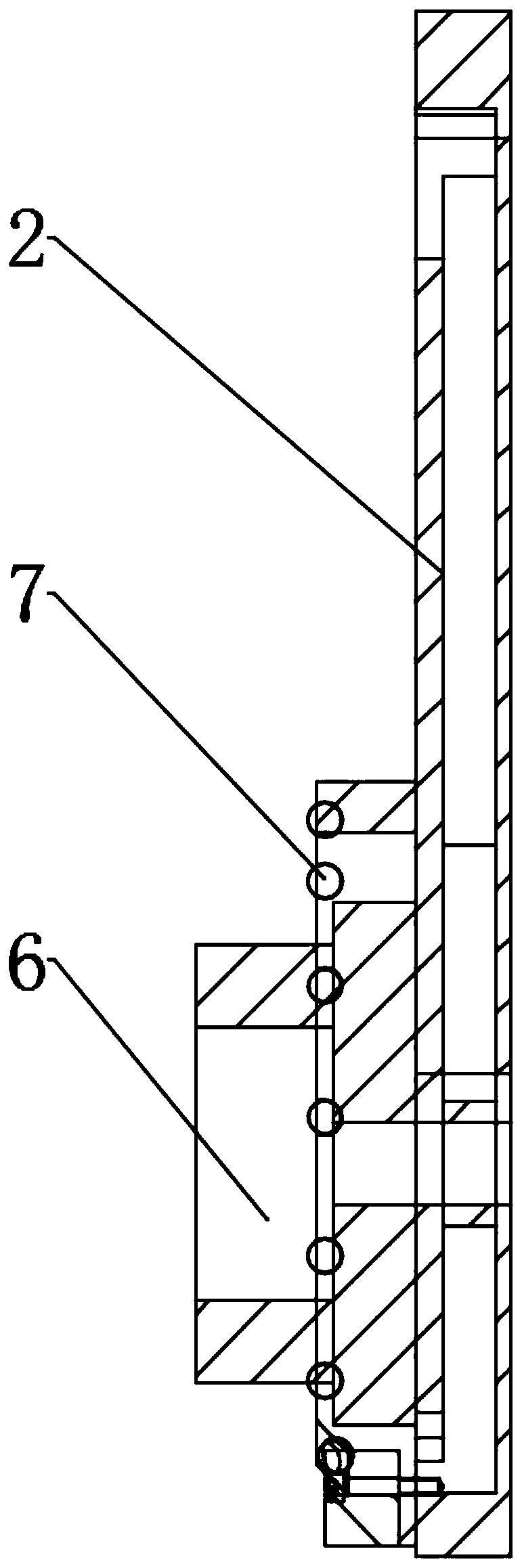

Structure and method for controlling state of medicine fog channel of moxibustion device according to postures

InactiveCN111449940APromote combustionBurning effectDevices for heating/cooling reflex pointsPhysical medicine and rehabilitationThermal insulation

The invention discloses a structure and method for controlling the state of a medicine fog channel of a moxibustion device according to postures. The structure comprises a grip, supporting arms, a roller, an operating button, a hollow rotating shaft, magnets, balls, an air guide piece, a linkage shaft, a vacuum pump, a spring, a sealing ring, an air channel column and a motor shaft, wherein the operating button is arranged at the top of the grip; the supporting arms are arranged on the two sides of the grip; the top of the supporting arm is sleeved with the hollow rotating shaft; the hollow rotating shaft is connected with the grip; the magnets are arranged at the tops of the supporting arms; the plurality of balls are arranged on the outer sides of the magnets; and the balls are connectedwith the supporting arms. According to the structure for controlling the state of the medicine fog channel of the moxibustion device according to the postures, a closed one-way air channel in a conveying process is established by adopting a high-temperature-resistant and thermal insulation material, so that moxa stick combustion is facilitated, medicine fog generated after the moxa stick combustion can be rapidly discharged, the situation that the moxa stick combustion is affected due to the fact that the medicine fog is retained in moxibustion equipment is avoided, and the effective medicinefog production rate of moxa sticks is improved.

Owner:广西励领农业科技有限公司

A cylinder head and method for visualizing flow field in a large diesel engine

InactiveCN105179099BDegree of renovationLarge flow field areaEngine testingCylinder headsCombustionCylinder head

Owner:SOUTH CHINA UNIV OF TECH

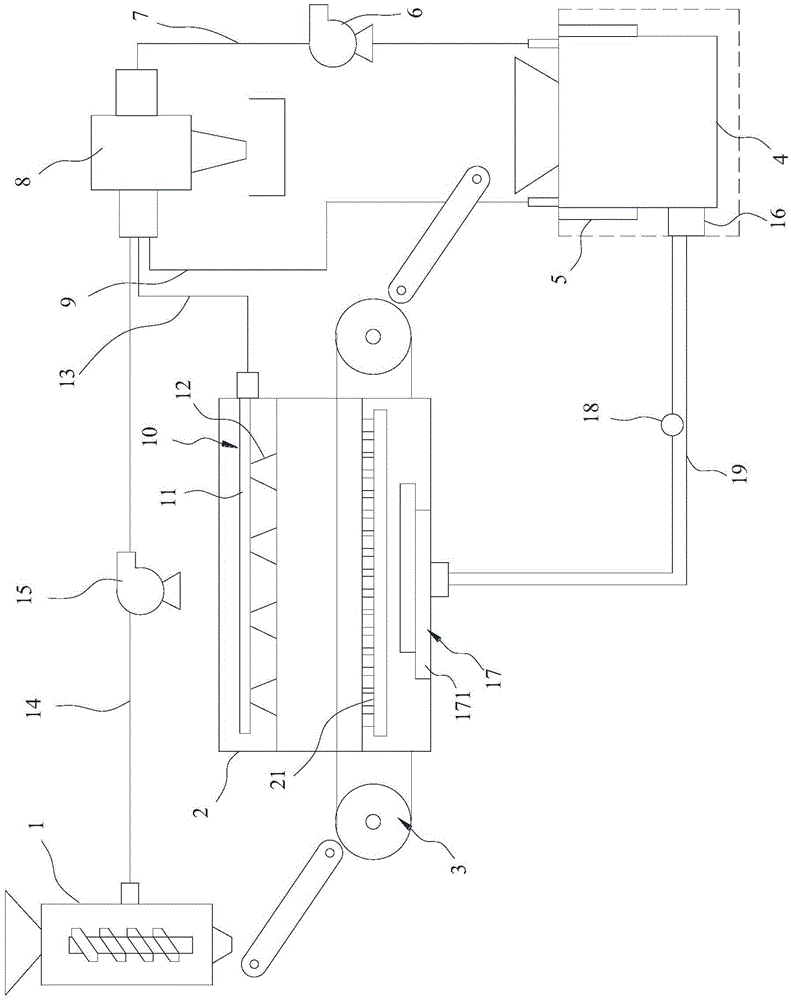

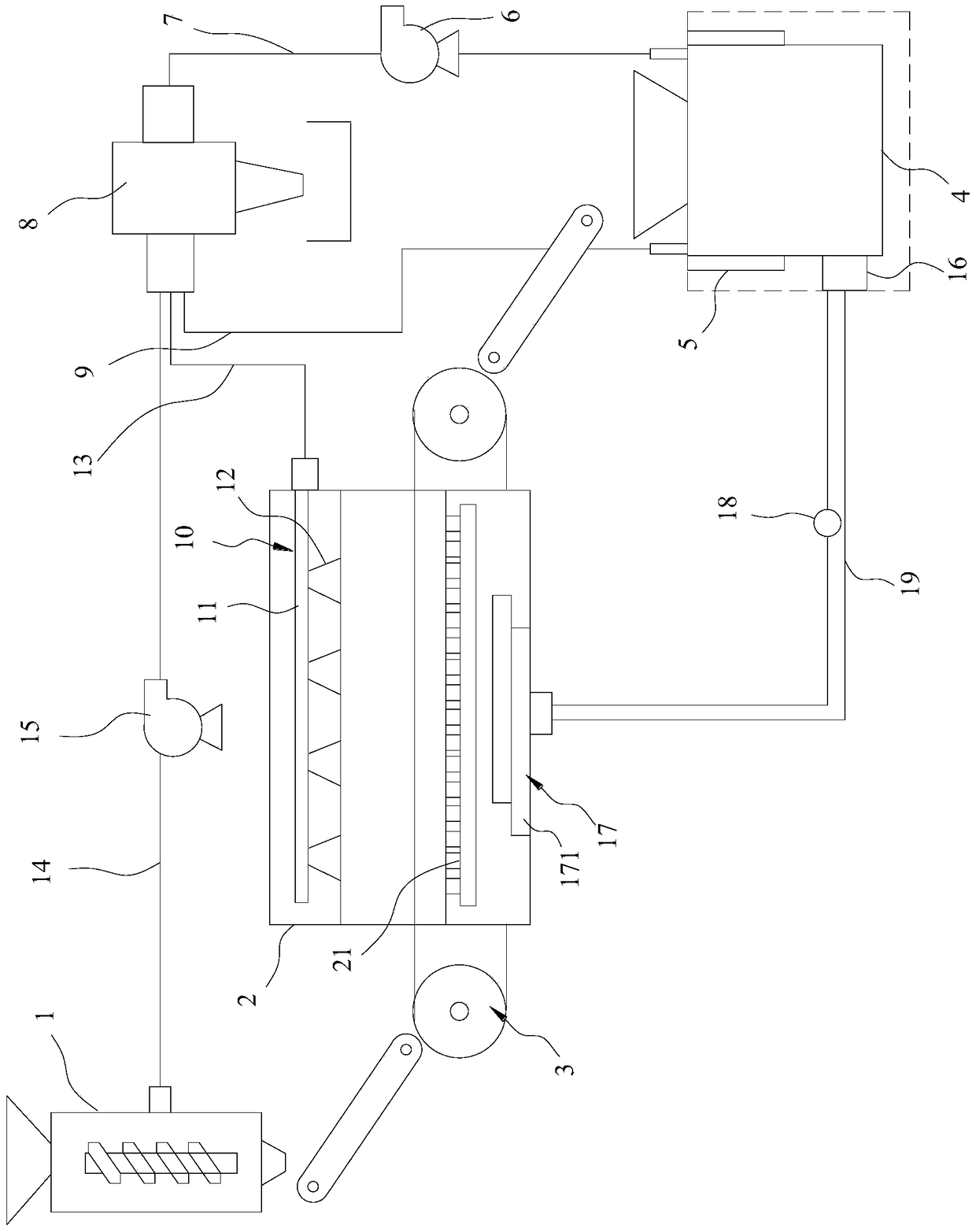

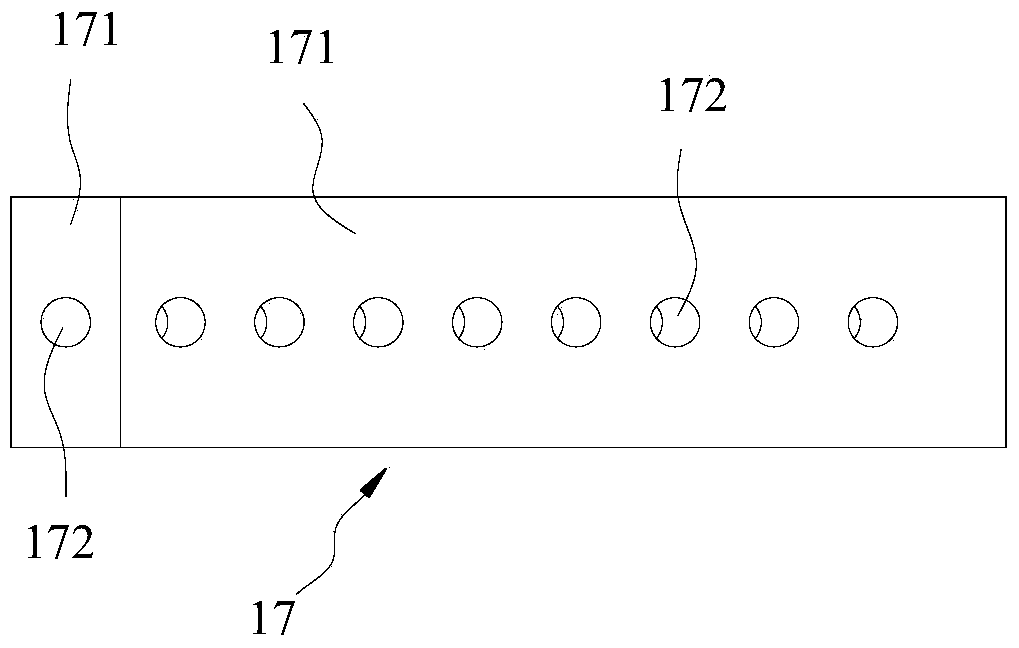

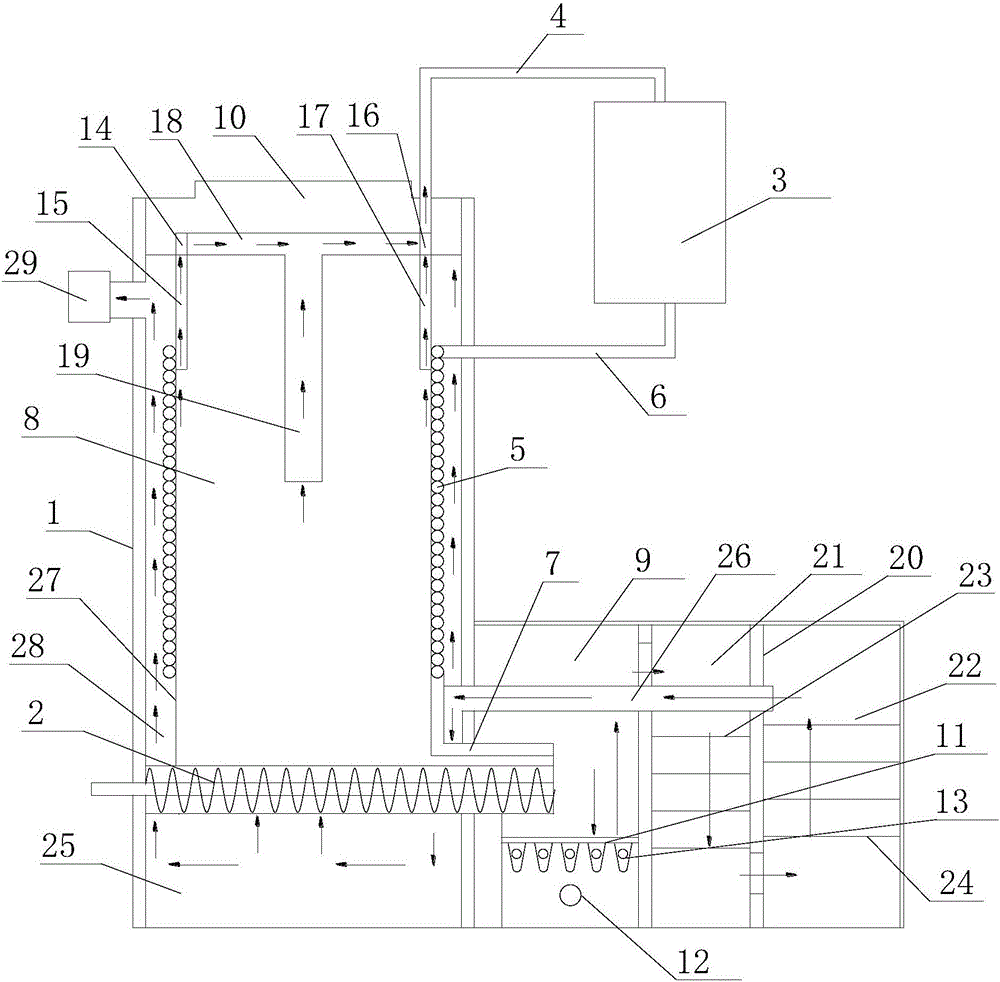

Multi-fuel-fired boiler for herb residue biomass fuels

ActiveCN105465799AImprove combustion efficiencyPrevent heat lossIncinerator apparatusThermal insulationPhencyclone

The invention discloses a multi-fuel-fired boiler for herb residue biomass fuels. The multi-fuel-fired boiler comprises a screw extrusion device, a dryer, a reciprocating conveying mechanism, a boiler body, an air feeding system, a vibrator and an energy saving unit, wherein the dryer is provided with a drying inlet and a drying outlet which are horizontal; a herb residue outlet of the screw extrusion device is in butt joint with the drying inlet; the drying outlet is in butt joint with a fuel inlet of the boiler body; the air feeding system comprises a first induced draft fan, a first thermal insulation tube, a cyclone separator, a second thermal insulation tube and an air distributing tube; a hot smoke outlet of the boiler body is connected to a smoke dust inlet of the cyclone separator through the first thermal insulation tube; one path of a clear air outlet of the cyclone separator is connected to an air inlet of the boiler body through the second thermal insulation tube; the other path of the clean air outlet is in butt joint with the air distributing tube; the boiler body is connected to a heating device of the dryer through the energy saving unit; and the vibrator is mounted on the boiler wall of the boiler body. The multi-fuel-fired boiler can effectively improve combustion efficiency, and avoids soot formation.

Owner:GUANGZHOU HUANFENG ENERGY TECH

Pulverized coal combustion performance detection method and device

InactiveCN112198271AImprove accuracyBurning effectChemical analysis using combustionProcess engineeringCoal

The invention discloses a pulverized coal combustion performance detection method and device, and and belongs to the technical field of pulverized coal combustion. The pulverized coal combustion performance detection device comprises a test container, the left side surface of the test container is fixedly connected with the right side surface of oxygenating equipment, an air inlet of the oxygenating equipment is clamped with an oxygen tank, and the lower surface of the oxygen tank is in lap joint with the inner wall of a support plate. According to the pulverized coal combustion performance detection method and device, oxygen supply equipment, a sealing ring and an observation window are arranged, so that the detection device can conveniently maintain the air pressure and the oxygen concentration content in the test container during detection, the oxygen concentration and the air pressure in the test container can be maintained at the level close to the outside oxygen concentration andthe air pressure, the combustion of pulverized coal in the test container can be comprehensively simulated to be nearly the same as the combustion of the pulverized coal combusted outside, the accuracy of the detection device in the pulverized coal combustion use detection process is greatly improved, and the test container cannot easily influence the combustion effect of the pulverized coal.

Owner:湖北赤焰热能工程有限公司

Burner air supply device

ActiveCN113404661ABurning effectPrevent backflowPositive displacement pump componentsPiston pumpsCombustorAir volume

The invention discloses a burner air supply device. The burner air supply device comprises an air inlet box body, the air inlet box body is a cylindrical hollow box body, a through hole is formed in the outer wall of the air inlet box body in a penetrating mode, and a stirring column in the air inlet box body is driven by a servo motor to rotate; when the stirring column rotates, a piston plate at the tail end of a piston rod can be driven by a transmission plate to do piston motion in an air blowing sleeve, and when the piston plate moves towards an air supply box, air in the air blowing sleeve can be discharged into the air supply box along an air guide sleeve and is discharged through an air supply pipe; a traditional fan blade air guide mode is replaced with a piston type air supply mode, the air guide amount can be effectively increased, combustion of the burner is not affected, and hot air backflow can be effectively prevented through the air supply box and an air guide sleeve; and meanwhile, when a rotating shaft drives the stirring column to rotate, the fan blades can be driven to rotate in the air guide sleeve, the fan blades can drive air to circulate, and heat dissipation can be effectively conducted on the device.

Owner:无锡路程科技有限公司

Methanol gasoline emulsifier and preparation method thereof

PendingCN114479960AEasy to prepareLow cost of preparationLiquid carbonaceous fuelsFuel additivesEthyl acetateDimethyl ether

The invention relates to a methanol gasoline emulsifier and a preparation method thereof.The methanol gasoline emulsifier comprises solvent oil, ethyl acetate, dimethyl ether and methyl tert-butyl ether.The methanol gasoline emulsifier has the advantages of being easy to prepare and low in preparation cost, can effectively improve intersolubility of gasoline and methanol in a low-temperature environment when used, and is good in emulsification effect, small in dosage and suitable for industrial production. Combustion of the methanol gasoline is not affected, and comprehensive popularization and application of the methanol gasoline are facilitated.

Owner:上海援鸣新能源科技集团有限公司

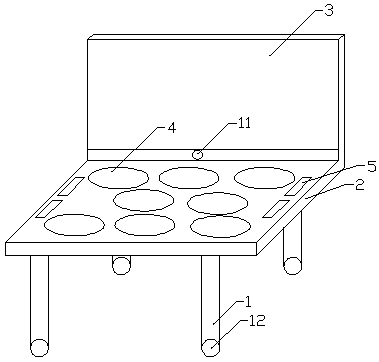

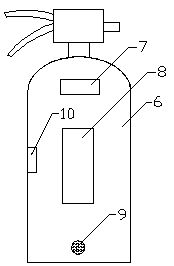

Fire-fighting equipment demonstration device applied to teaching

InactiveCN109903623AImprove motivation and funBurning effectCosmonautic condition simulationsSimulatorsLiquid-crystal displayCarbon dioxide

The invention discloses a fire-fighting equipment demonstration device applied to teaching. The demonstration device comprises supporting legs, an operation panel and a liquid crystal display, a plurality of simulation grooves are formed in the upper surface of the operation panel, a plurality of extinguisher placing grooves are formed in two sides of each simulation groove, different kinds of extinguishers are placed in the extinguisher placing grooves, each extinguisher is provided with a display screen, a label area and an inflation inlet, a pressure sensor is arranged in each extinguisher,the liquid crystal display is fixedly arranged on one side of the operation panel, a video watching mode replaces an oral account mode of a teacher, enjoyment and motivation of students are improved,learning effects of the students can be deepened by simulation training, air is charged into the extinguishers through the inflation inlet and replaces carbon dioxide, the pressure sensors in the extinguishers monitor pressure in the extinguishers and view whether operations of the students are successful or not, and energy is saved.

Owner:SHAANXI HUABANG TECH DEV CO LTD

A Boiler with Biomass Fuel Co-fired with Dregs

ActiveCN105465799BAvoid getting lostImprove combustion efficiencyIncinerator apparatusThermal insulationPulp and paper industry

Owner:GUANGZHOU HUANFENG ENERGY TECH

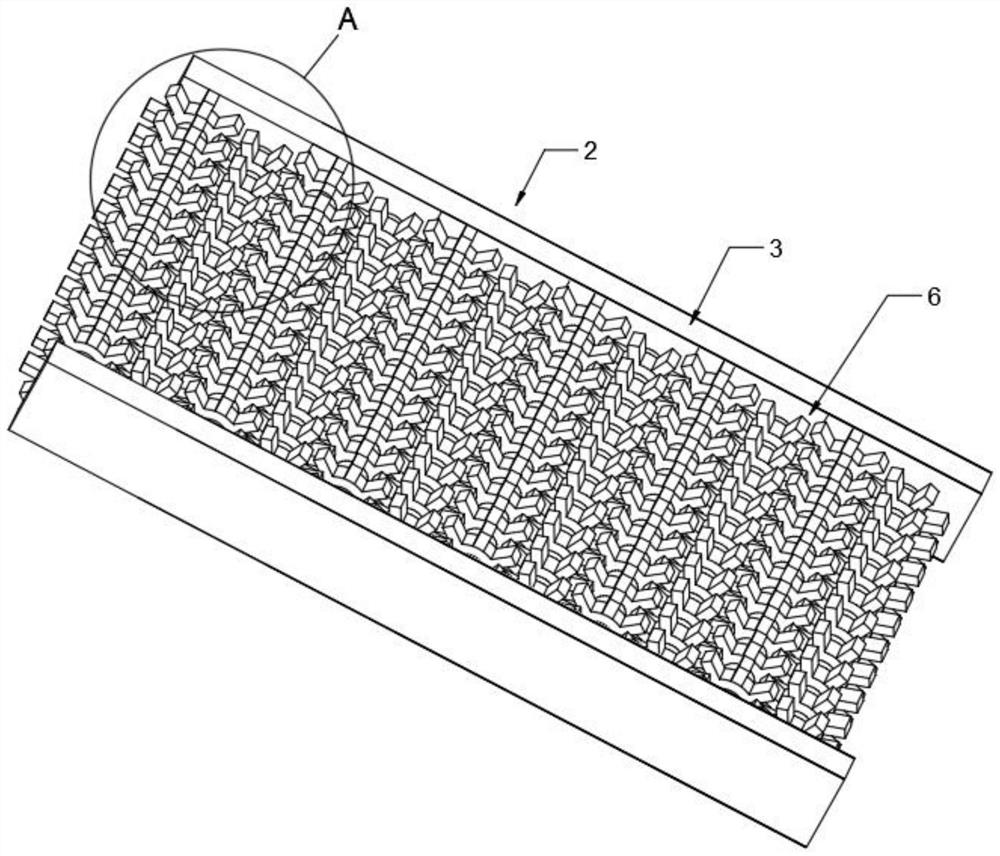

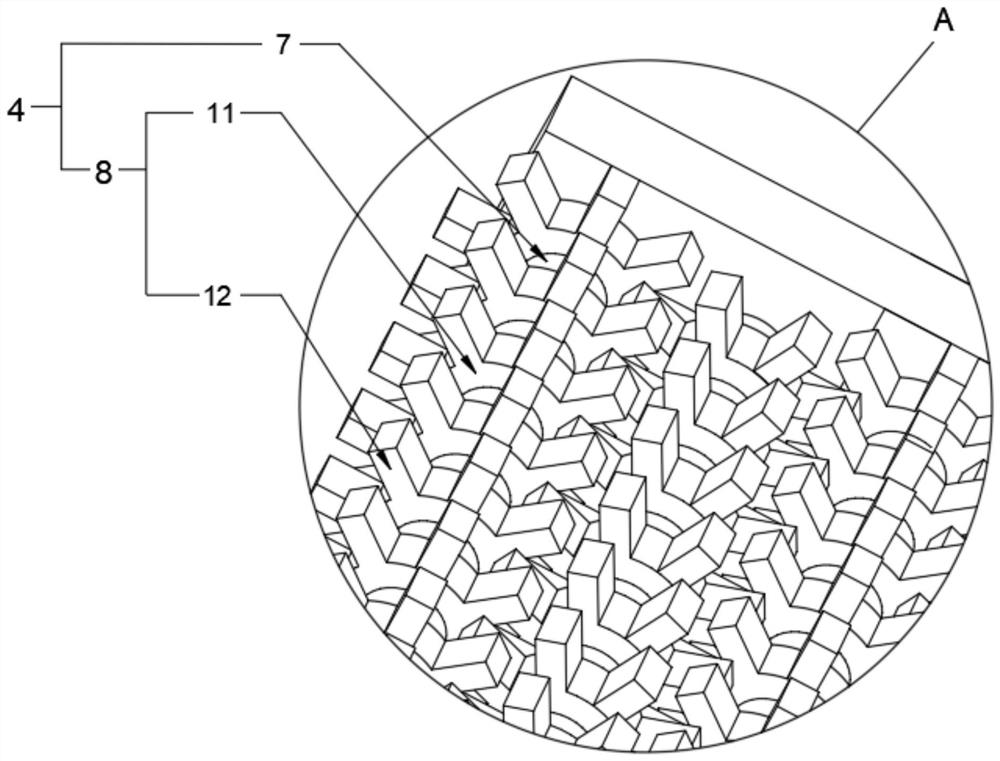

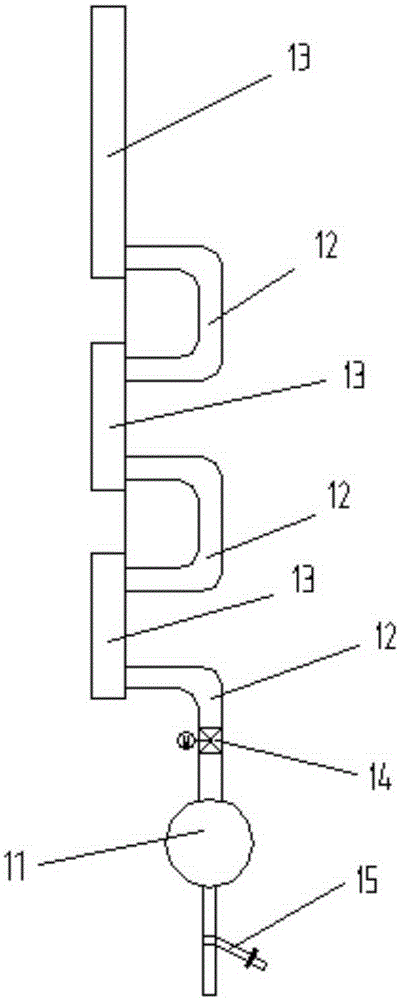

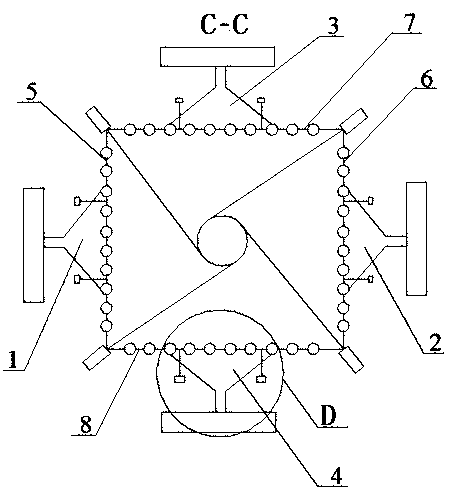

Closing-to-wall air system for preventing high temperature corrosion of water wall of four-corner tangential firing boiler, and working method thereof

PendingCN109458631ABurning effectReduce wind speed attenuationAir supply regulationAir/fuel supply for combustionCooling effectActuator

The invention relates to a closing-to-wall air system for preventing high temperature corrosion of a water wall of a four-corner tangential firing boiler, and a working method thereof. The closing-to-wall air system comprises a front wall burner area closing-to-wall air device, a rear wall burner area closing-to-wall air device, a left wall burner area closing-to-wall air device and a right wall burner area closing-to-wall air device; the front wall burner area closing-to-wall air device, the rear wall burner area closing-to-wall air device, the left wall burner area closing-to-wall air deviceand the right wall burner area closing-to-wall air device are located on a front wall water wall, a rear wall water wall, a left wall water wall and a right wall water wall separately; and the rightwall burner area closing-to-wall air device comprises a curved baffle, a closing-to-wall air box, a regulation actuator, a tapered plug, a regulating connecting rod, an air duct, a regulation air door, a main pipe, an A wall surface condition monitor and a B wall surface condition monitor. The closing-to-wall air system has the characteristics of wide cover area, capability of fine regulation, slow wind speed attenuation, good cooling effect of nozzles and the like.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

Garbage incineration treatment device

The invention provides a garbage incineration treatment device. A furnace body is provided with a material storage cavity and a combustion cavity; a spiral feeding mechanism is used for transporting materials in the material storage cavity into the combustion cavity for combustion; a fist pipe set comprises a fifth air guiding pipe and a plurality of sixth air guiding pipes, and a second pipe set comprises a seventh air guiding pipe and a plurality of eighth air guiding pipes; a third pipe set comprises a plurality of ninth air guiding pipes and a plurality of tenth air guiding pipes; the air feeding end of the first air guiding pipe communicates with the seventh air guiding pipe, and the air discharging end of the first air guiding pipe stretches out of the furnace body to communicate with an air feeding opening of a condensation water removal mechanism; the air discharging end of a third air guiding pipe communicates with the air feeding end of a second air guiding pipe, and the air feeding end of the third air guiding pipe stretches out of the furnace body to communicate with an air discharging opening of the condensation water removal mechanism; and the air feeding end of a fourth air guiding pipe communicates with the air discharging end of the second air guiding pipe, and the air discharging end of the fourth air guiding pipe stretches into the combustion cavity. The combustion cavity is separately arranged in the furnace body so that the temperature in the combustion chamber can be relatively concentrated, garbage can be fully combusted in the combustion chamber, and garbage combustion efficiency is greatly improved.

Owner:SINOBIOWAY DINGHE ENVIRONMENTAL PROTECTION CO LTD

Protection device for biomass power-generation equipment

ActiveCN111716795ABurning effectDrying solid materials without heatIncinerator apparatusAgricultural scienceAgricultural engineering

The invention provides a protection device for biomass power-generation equipment. The protection device comprises a main frame, a baffle and a conveying belt, the two sides of the middle of the mainframe are connected with transmission motors, and the transmission motors rotate to drive the conveying belt to rotationally move to convey crushed biomass agricultural plant waste. The protection device is characterized in that a squeezing assembly is arranged on a displacement block in an embedded mode, and the displacement block is slidably connected to the conveying belt in an embedded mode through a reset shaft on the right side. The protection device for the biomass power-generation equipment is provided with the squeezing assembly, and water and juice contained in crops are squeezed outand collected through the squeezing assembly, so that the situations that when the crops enter a boiler, combustion is troublesome due to the water and juice contained in the crops, and meanwhile, alot of dense smoke with peculiar smell is prone to being generated are avoided, and the water and juice in crop plants are prevented from being accumulated in the boiler to affect boiler combustion.

Owner:蓝添财

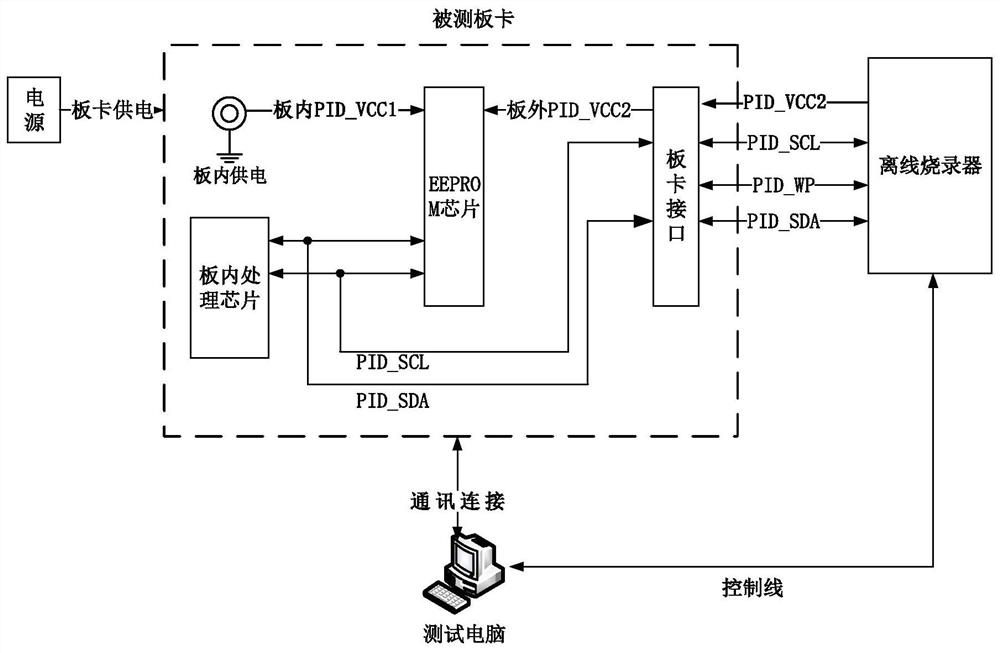

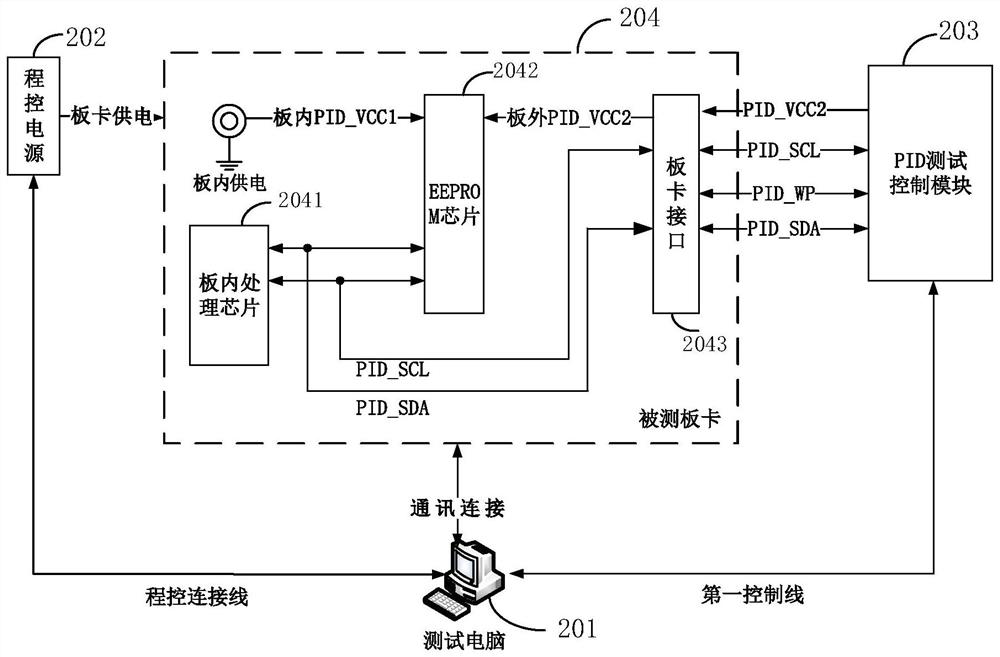

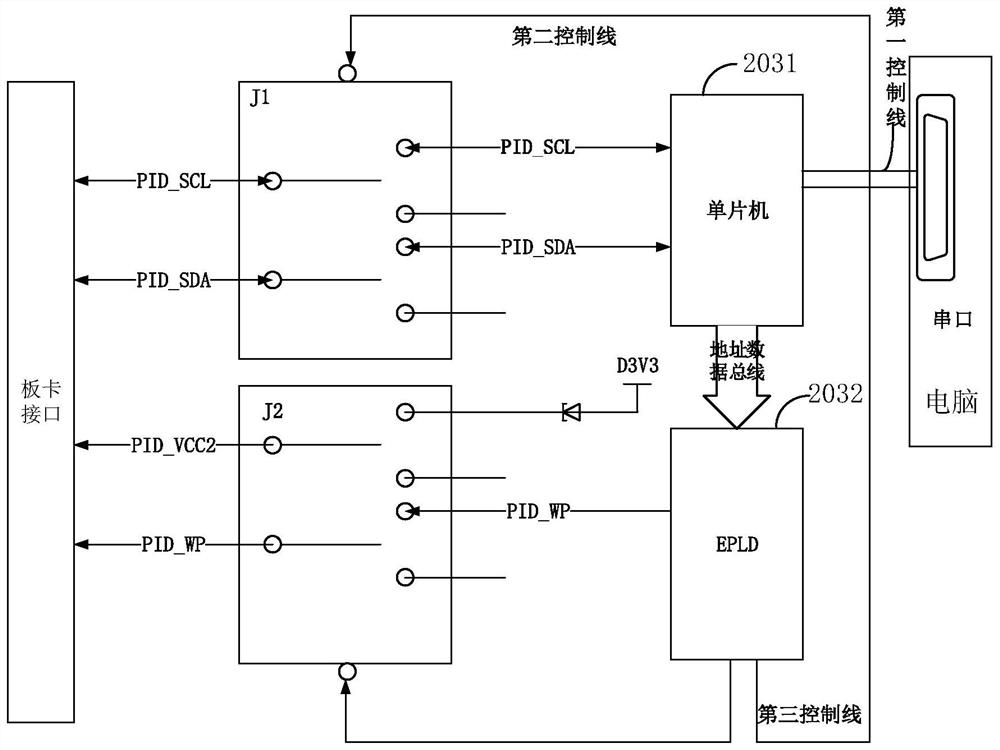

Product identification information burning test system and method

PendingCN114860513ABurning effectSolve the full coverage test problemDetecting faulty hardware by configuration testFaulty hardware testing methodsControl engineeringOnline and offline

The embodiment of the invention provides a product identification information burning test system and method, the system comprises a test computer and a programmable power supply, and further comprises a product identification information PID test control module, the test computer is connected with the PID test control module through a first control line, and one end of the first control line is connected to a serial port of the test computer; the test computer is connected with the programmable power supply through a programmable connecting line; the PID test control module is connected with a board card interface of the tested board card; and the PID test control module is used for receiving the signal / command sent by the test computer, controlling the connection state with the board card interface based on the signal / command, and realizing on-line burning and off-line burning of the product identification information. According to the embodiment of the invention, by adding the PID test control module, the control of online burning and offline burning of the product identification information is realized, and the full coverage test problem and interference problem of the online and offline interface power supply interface are solved.

Owner:SHANGHAI ULTIMATE POWER COMM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com