Garbage processing incinerator capable of preheating and dewatering

A technology of garbage disposal and incinerator, applied in the direction of incinerator, combustion method, combustion type, etc., can solve the problems of harmful gas generation, impact on garbage combustion, insufficient combustion, etc., achieve thorough cleaning, improve garbage processing capacity, and save cleaning effect of difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

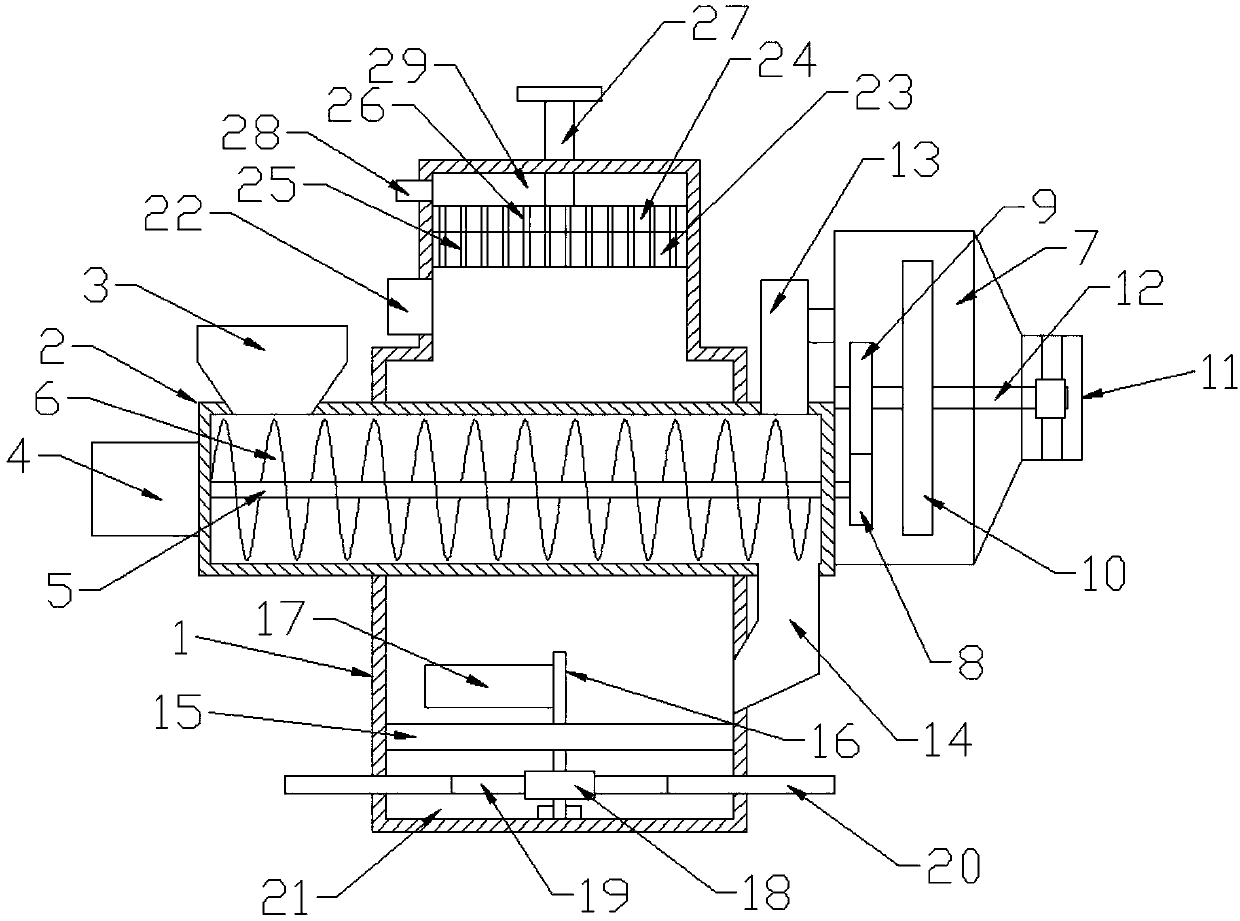

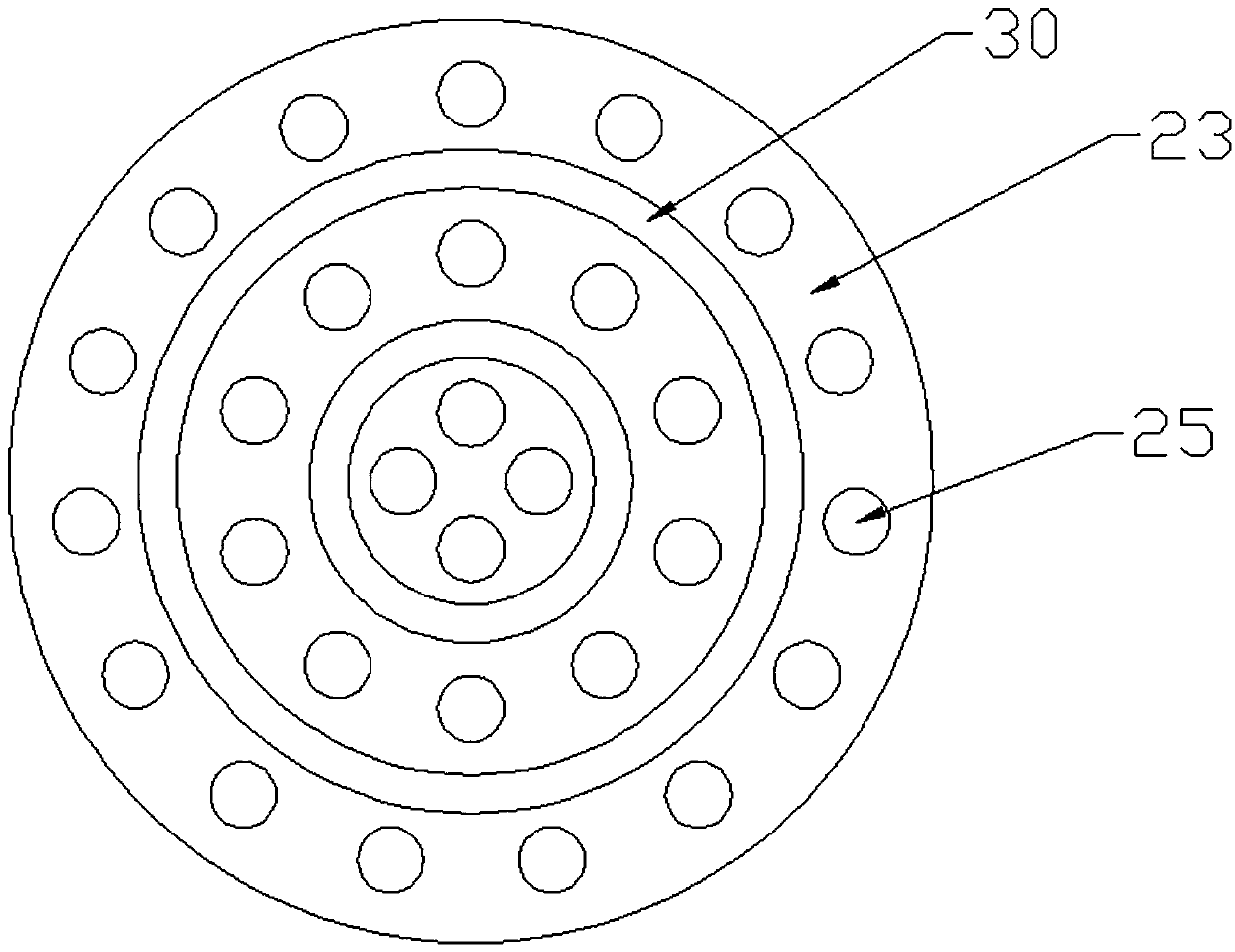

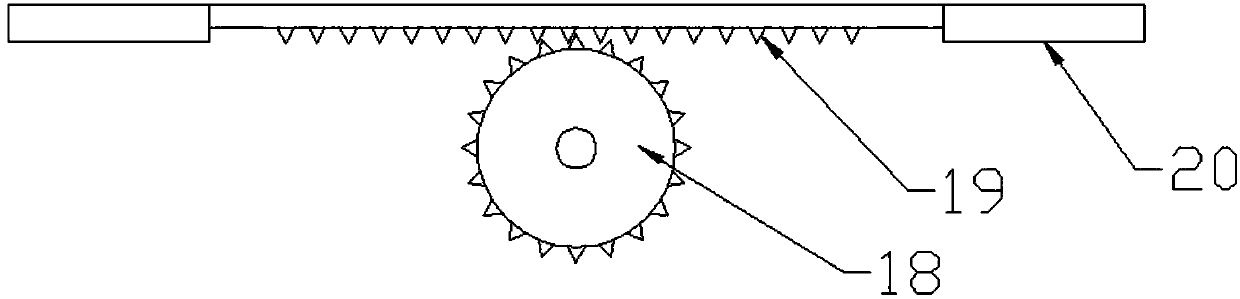

[0019] Please refer to the figure, in the embodiment of the present invention, a preheating and dewatering garbage treatment incinerator includes a shell 1, a drying cylinder 2, a feed hopper 3 and a motor 4; the drying cylinder 2 is horizontally installed in the The upper part of the housing 1, the housing 1 and the drying cylinder 2 are independent of each other, and the inside is not connected. The high temperature in the housing 1 increases the temperature in the drying cylinder 2 to heat the garbage in the drying cylinder 2; A motor 4 is fixedly installed on one end of the drying cylinder 2, and the output shaft of the motor 4 extends horizontally into the drying cylinder 2, and a horizontal transmission shaft 5 is fixedly connected to the output shaft of the motor 4, and the other end of the transmission shaft 5 passes through the Out of the drying cylinder 2, the transmission shaft 5 is located on the central axis of the drying cylinder 2, and the helical blade 6 is fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com