Pulverized coal combustion performance detection method and device

A pulverized coal combustion and detection device technology, which is applied in the direction of chemical analysis using combustion, can solve the problems of oxygen pulverized coal combustion process transformation and result influence, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

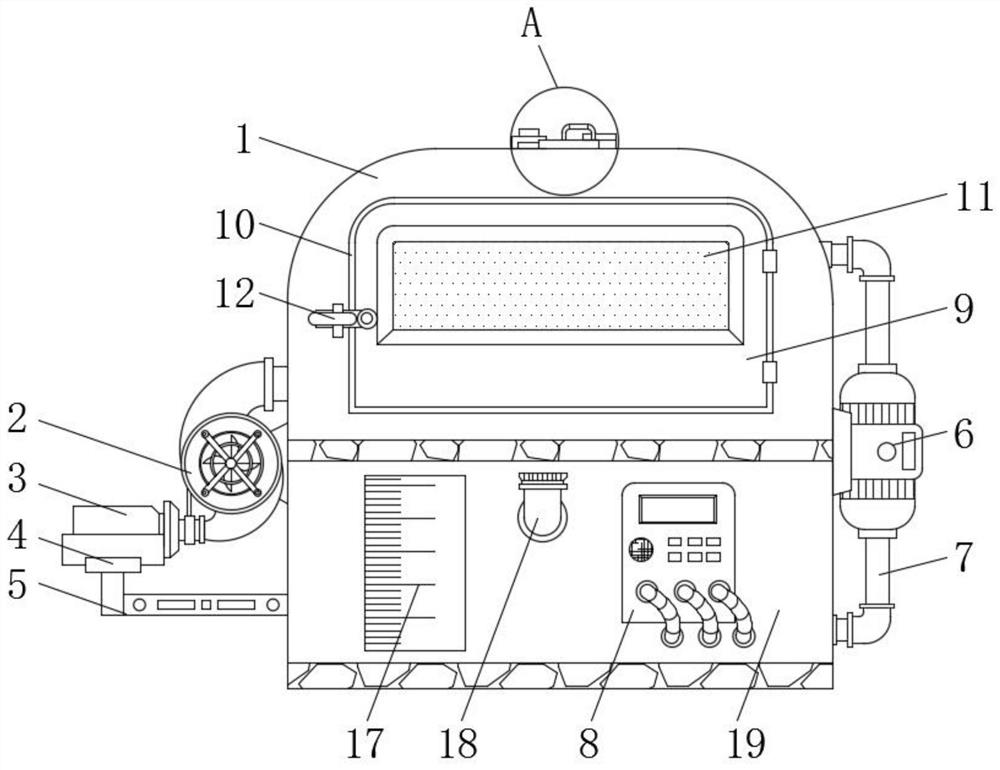

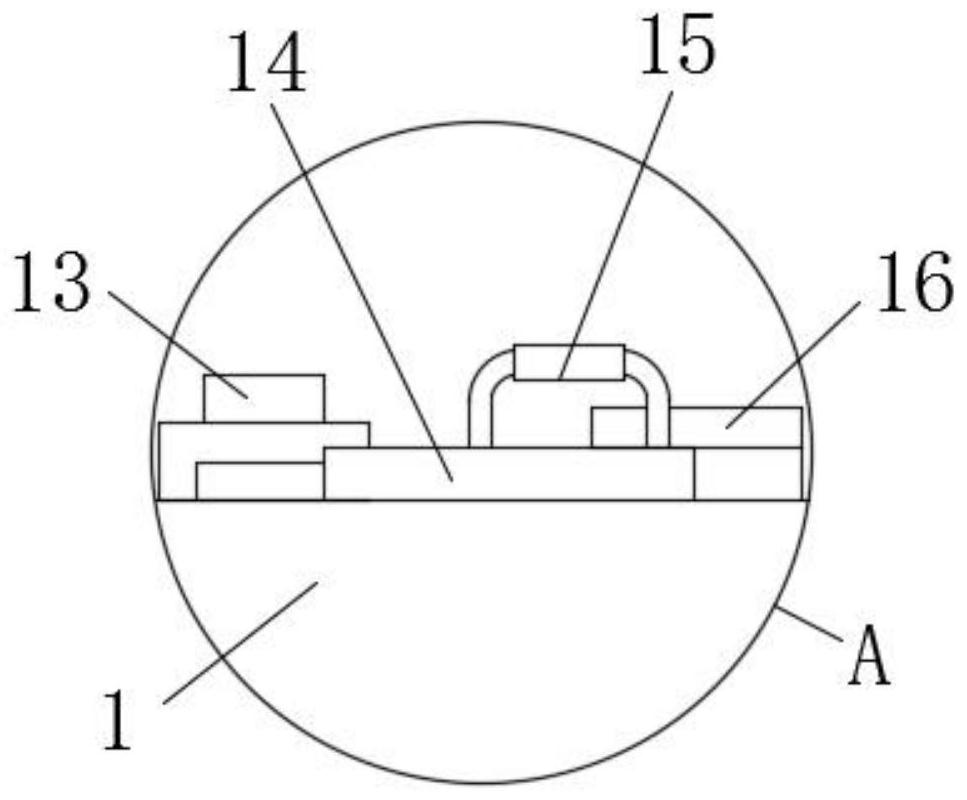

[0038] Embodiment 1: When the pulverized coal burns in the test container 1, the staff can check the oxygen content and pressure value in the test container 1 through the control panel 8, and when the oxygen content in the test container 1 is too low, the staff will The oxygenation device 2 can be started, and the oxygen in the oxygen tank 3 can be filled into the test container 1 through the oxygenation device 2, so as to reduce the oxygen concentration in the test container 1. When the oxygen concentration in the test container 1 is greater than 40%, and the test When the pressure inside the container 1 is greater than 150kPa, the test container 1 is prone to rupture.

Embodiment 2

[0039] Embodiment 2: When the pulverized coal burns in the test container 1, the staff can check the oxygen content and pressure value in the test container 1 through the control panel 8, and when the oxygen content in the test container 1 is too low, the staff will The oxygenation device 2 can be started, and the oxygen in the oxygen tank 3 can be filled into the test container 1 through the oxygenation device 2, so as to reduce the oxygen concentration in the test container 1. When the oxygen concentration in the test container 1 is less than 10%, and the test When the pressure in the container 1 is less than 60kPa, the pulverized coal in the test container 1 is difficult to ignite.

[0040] Draw the following table according to embodiment 1-2:

[0041] oxygen concentration pressure Affect the burning effect Example 1 ≥40% ≥150kPa container breaks easily Example 2 ≤10% ≤60kPa Pulverized coal is difficult to ignite

[0042] From the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com