Intelligent water wall high temperature corrosion preventing system suitable for large power station boiler and method

A power plant boiler, high-temperature corrosion technology, applied in the direction of combustion method, combustion chamber, outer cover/lining, etc., can solve the problems of low side wind speed, small wall-attached air volume, human error, etc., to prevent high-temperature corrosion, The effect of small construction workload and reduced workload

- Summary

- Abstract

- Description

- Claims

- Application Information

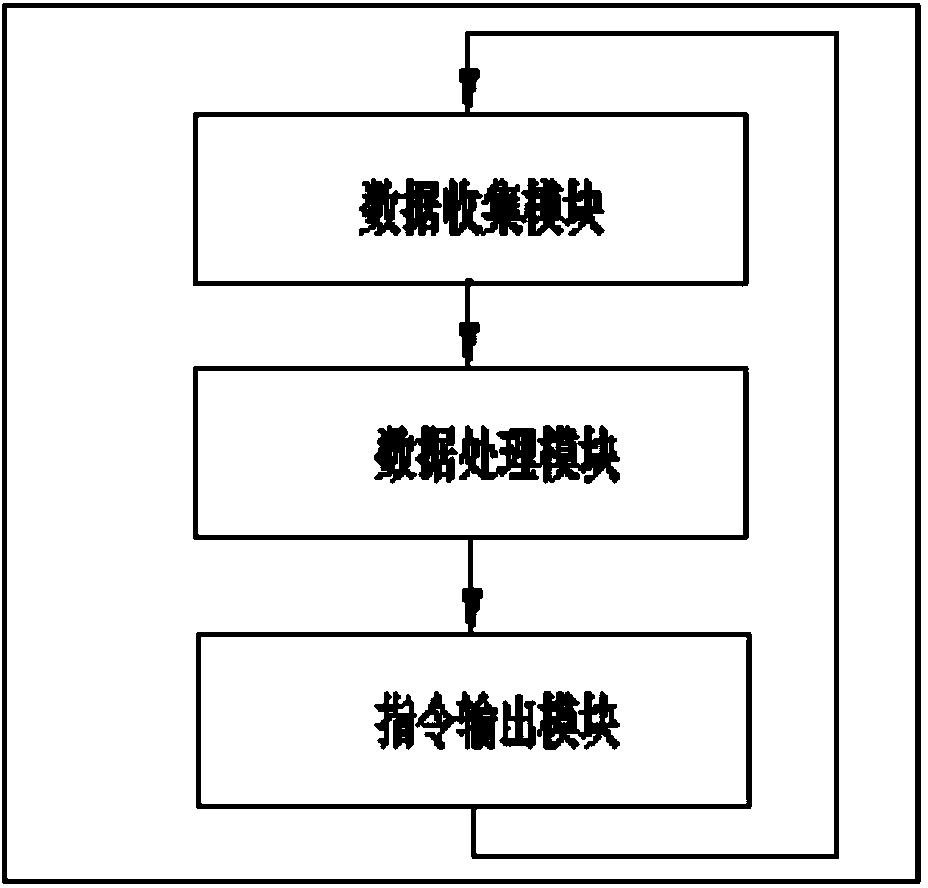

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

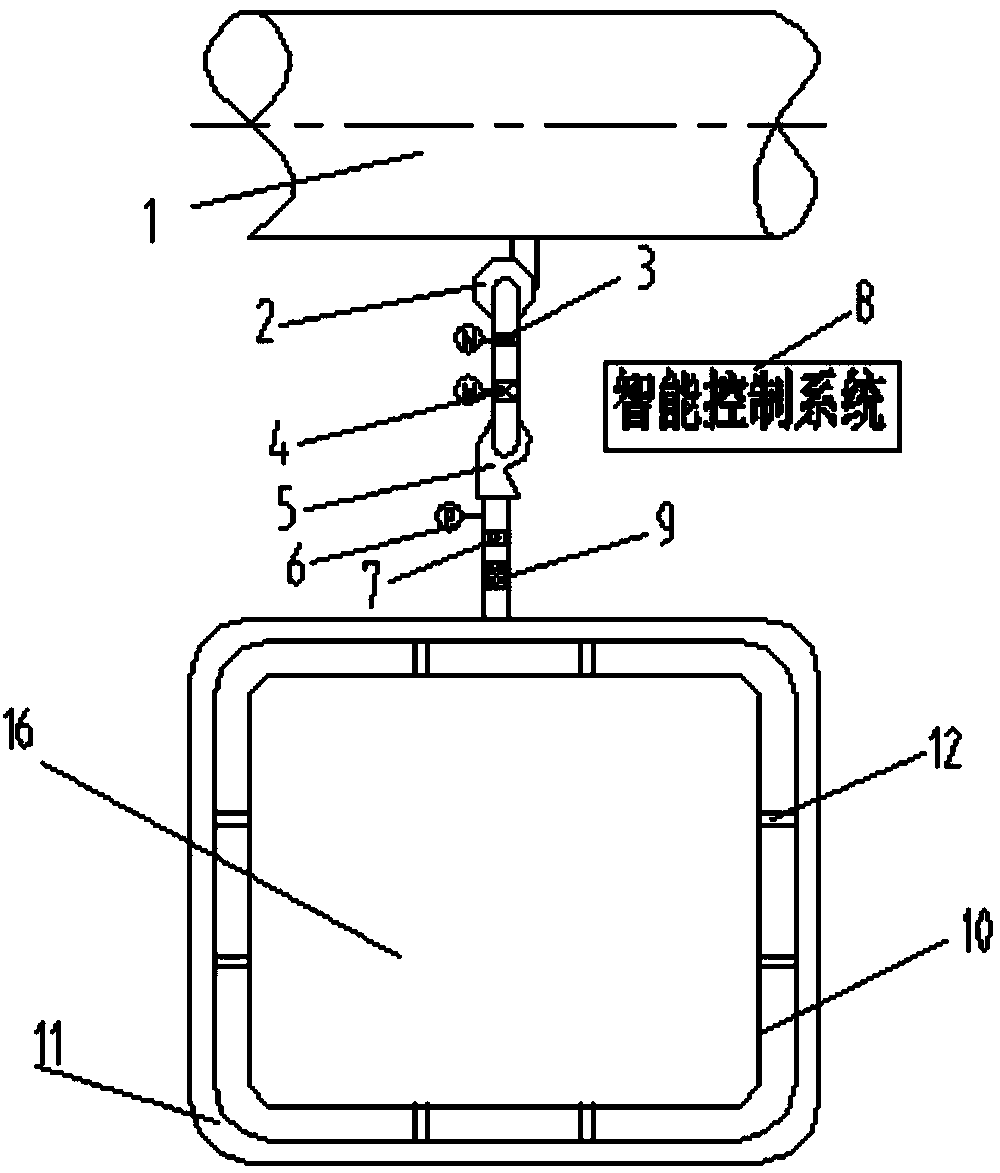

Embodiment 1

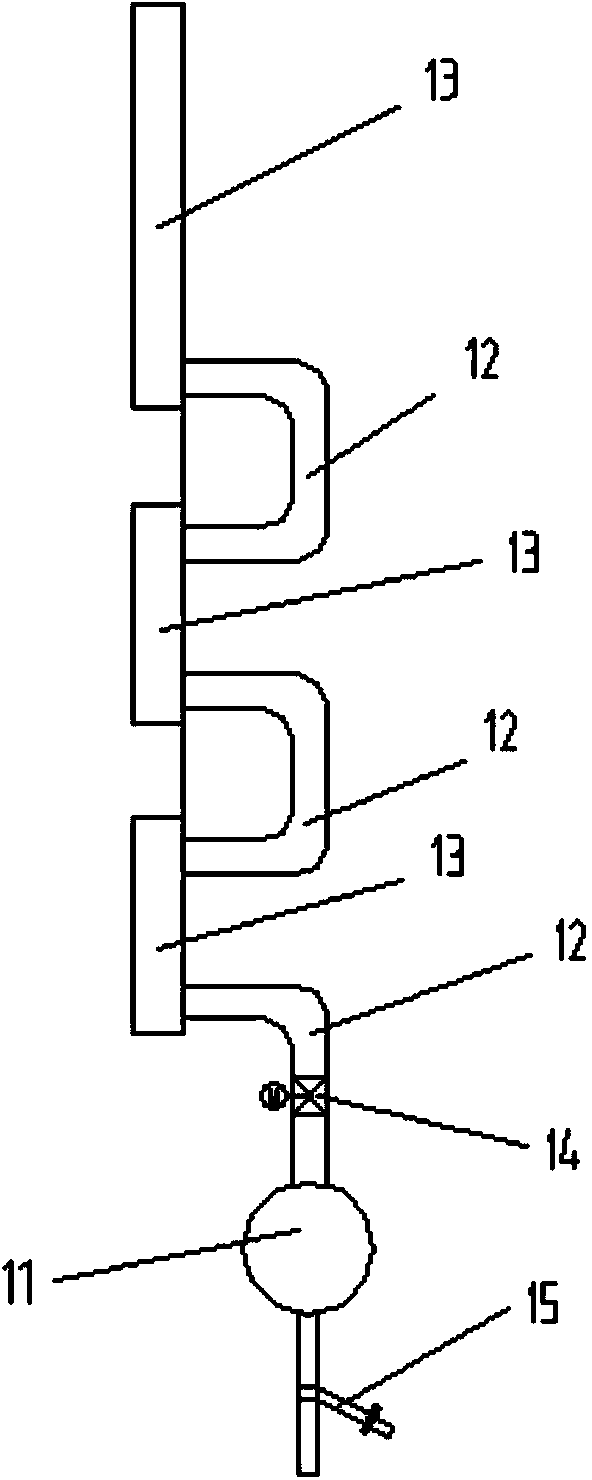

[0064] Boiler #4 of a power plant of Huaneng Group is a subcritical, intermediate reheating, forced circulation drum boiler with an evaporation capacity of 1025t / h. The air nozzles are arranged at intervals, and the pulverizing system is a direct blowing type equipped with 6 medium-speed coal mills. The boiler burner adopts the early American CE technology, and the NOx emission concentration is relatively high, and the emission concentration is about 600mg / Nm3. In order to meet the latest national pollutant emission standards for thermal power plants, boiler #4 underwent low-nitrogen combustion transformation in 2010. In order to accurately grasp the surface atmosphere of the water-cooled wall, a gas measurement system on the surface of the water-cooled wall was installed, which can measure the gas on the surface of the water-cooled wall in real time. Oxygen and carbon monoxide, by analyzing the measured real-time data, it is found that, when the boiler is operating at rated l...

Embodiment 2

[0071] The #6 boiler in a power plant of Huadian Group is a subcritical, intermediate reheating, and natural circulation drum boiler with an evaporation capacity of 1021t / h. The air nozzles are arranged at intervals, and the pulverizing system is a medium-storage type equipped with 4 steel ball coal mills. The boiler burner adopts the early American CE technology. In order to meet the latest national pollutant discharge standards for thermal power plants, boiler #6 underwent low-nitrogen combustion transformation in 2011, and four layers of SOFA nozzles were arranged above the main burner. Due to changes in the coal market, the main coal used by the boiler is now The sulfur content of the coal is relatively high, and the annual average sulfur content of the coal is about 2.0%, which is much higher than the design coal type of the boiler. Moreover, the low-nitrogen combustion method is adopted, and the oxygen deficiency in the main combustion area of the boiler is more seriou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com