Efficient biomass fuel boiler

A biomass fuel and boiler technology, applied in the field of boilers, can solve the problems of difficult cleaning of ashes, low steam generation efficiency, insufficient fuel combustion, etc., and achieve the effects of improving generation efficiency, convenient and quick discharge and cleaning, and sufficient combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

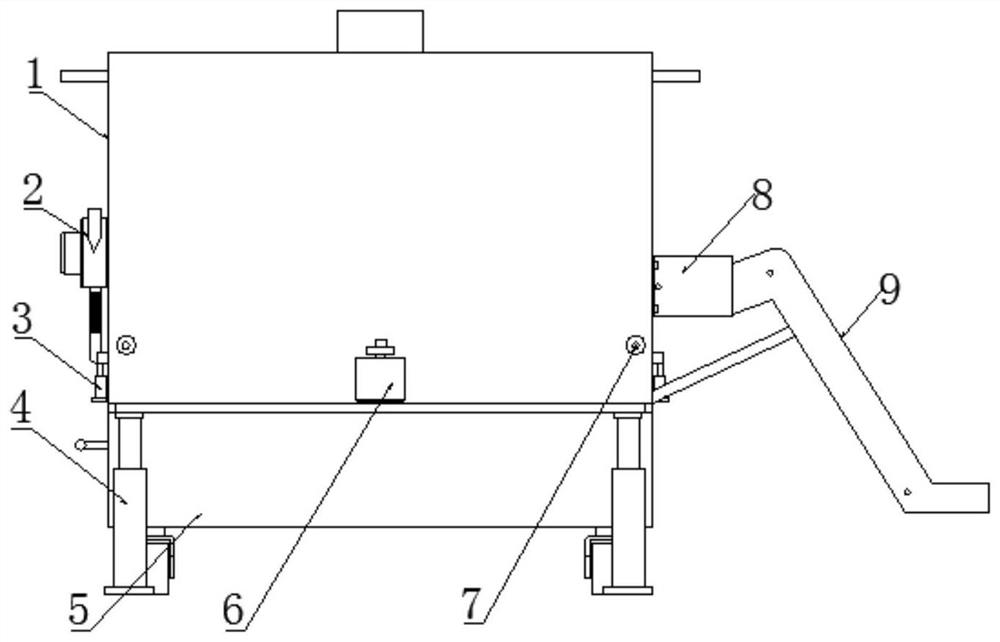

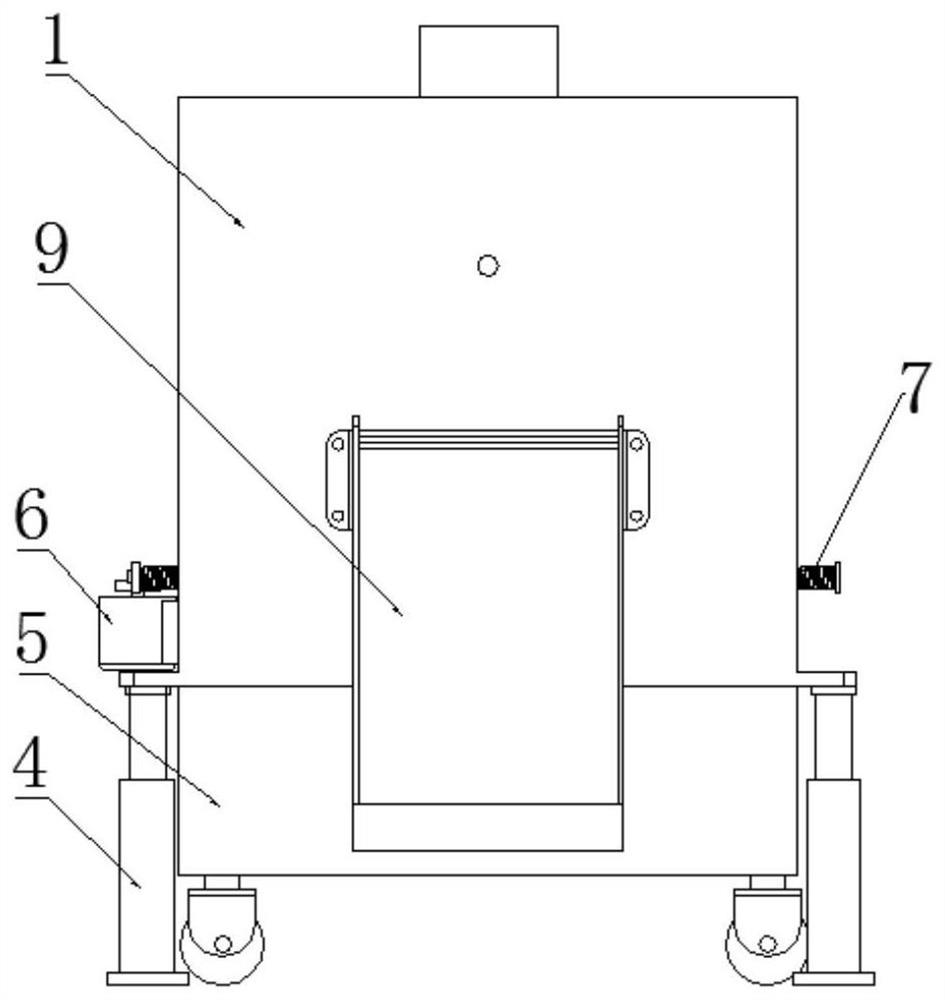

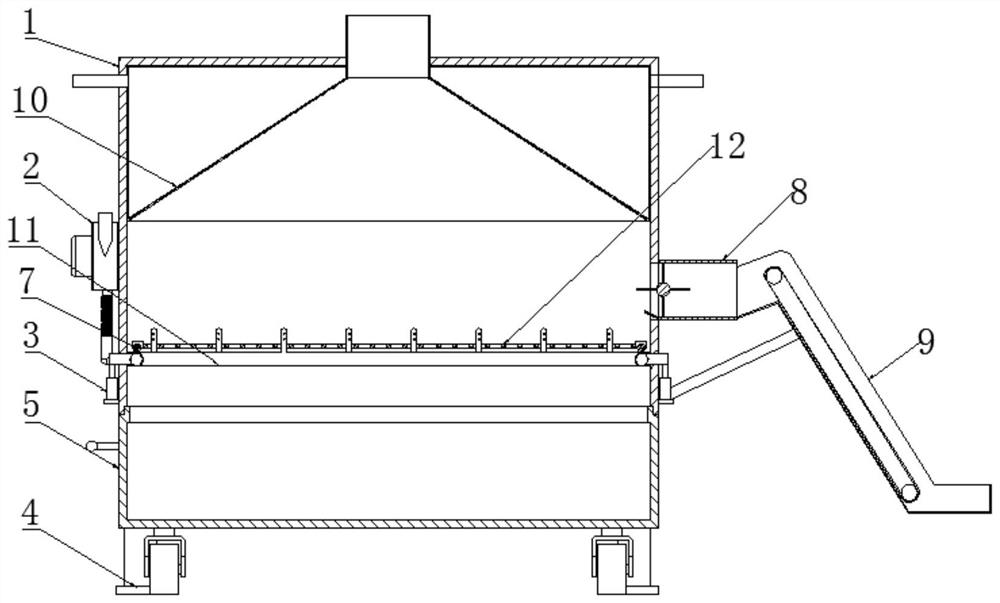

[0035] Example 1, please refer to figure 1 , figure 2 , image 3 with Figure 4 , a high-efficiency biomass fuel boiler, including a furnace body 1, a storage box 5 and a feeder 9, a detachable and movable storage box 5 is provided at the lower end of the furnace body 1, and the upper end of the storage box 5 is stuck on the furnace body 1 The lower port of the lower port is convenient for the disassembly of the material storage box 5. The material storage box 5 is provided to collect the ashes under the combustion rack 12. The lower end surface of the furnace body 1 is located at the front and rear sides of the material storage box 5. The legs 4 and the lifting legs 4 realize the lifting of the body of furnace 1 to facilitate the separation of the storage box 5. The end face of the body of furnace 1 is provided with a material guide mechanism 8, and the right end side of the material guide mechanism 8 is provided with a lifter 9. The feeder 9 is fixedly connected with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com