Anti-slagging incinerator with rotary blade fire grate

An incinerator and anti-slagging technology, applied in incinerators, combustion types, combustion equipment, etc., can solve the problems of inability to replenish oxygen in time, easy to block the grate, and artificially open the furnace, and achieve the effect of smooth ventilation and oxygen intake.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

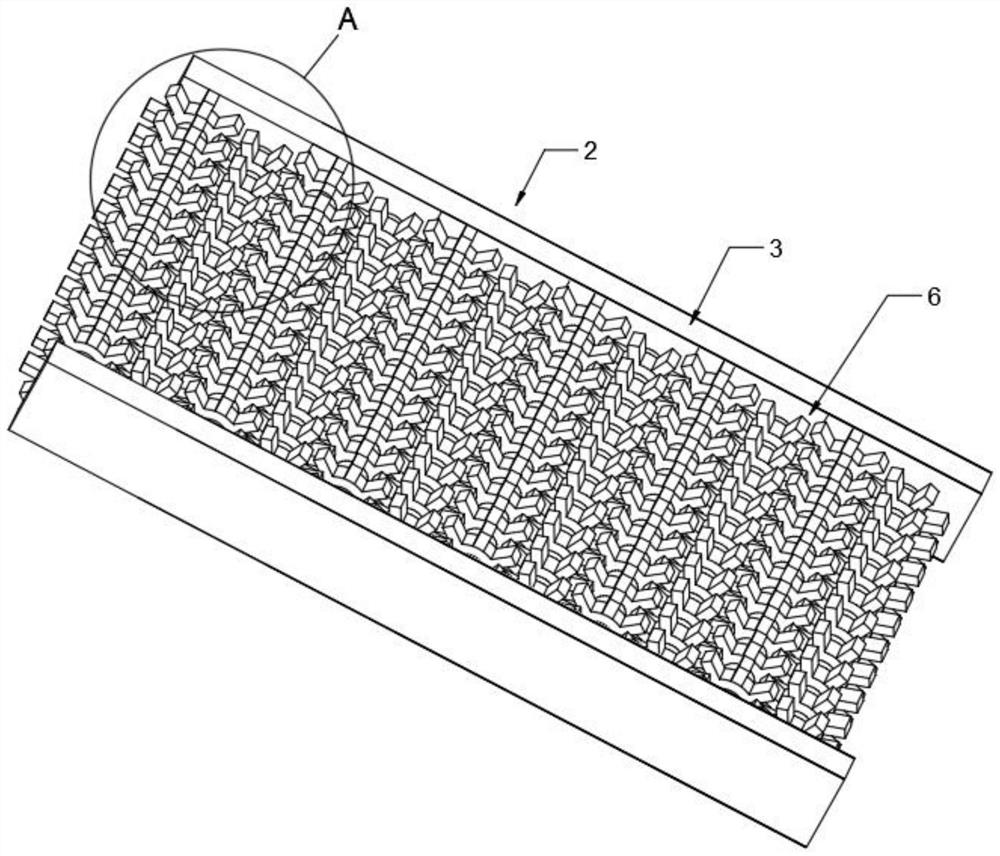

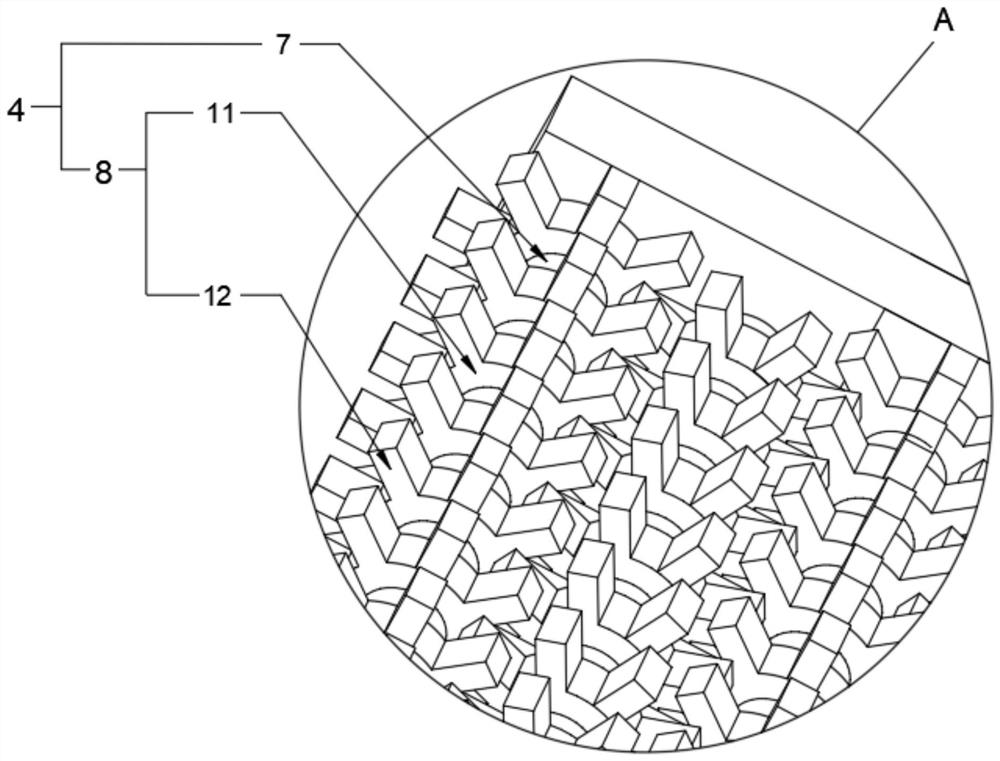

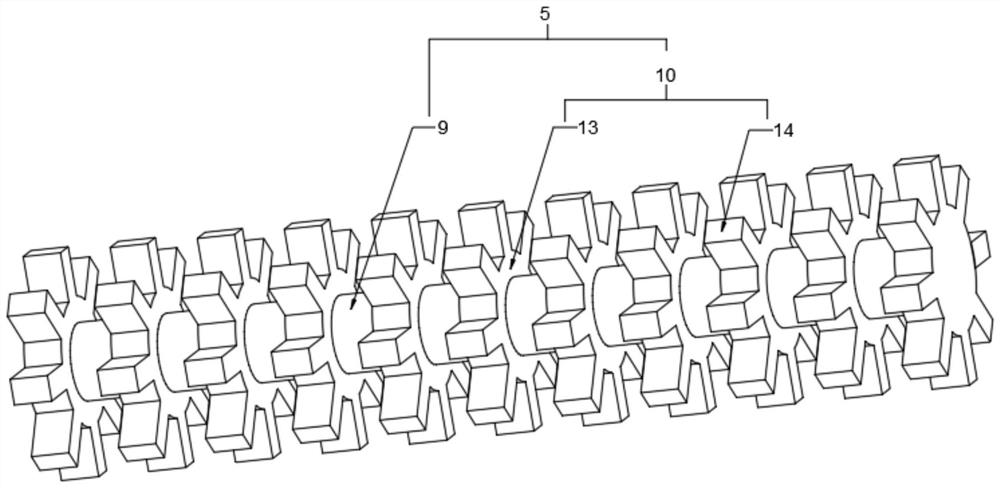

[0027] Embodiment one, as Figure 1 to Figure 3 As shown, a kind of anti-slagging incinerator with rotary blade grate includes an incinerator body 1 and a blade type grate furnace 2, the blade type grate furnace 2 is obliquely arranged in the incinerator body 1, and the blade type grate furnace 2 includes a grate frame 3, the grate frame 3 is fixedly arranged on the inner wall of the incinerator body 1, and the grate frame 3 is provided with a plurality of first grate mechanisms 4 and a plurality of second grate mechanisms 5, the first furnace The grate mechanism 4 and the second grate mechanism 5 are interlaced with each other, and an inclined material transfer channel 6 is formed between a plurality of first grate mechanisms 4 and a plurality of second grate mechanisms 5, and the material transfer channel 6 is in the shape of a feeding The end is high and the discharge end is low. The first grate mechanism 4 includes a first rotating shaft 7 and a first blade mechanism 8. Th...

Embodiment 2

[0029] Embodiment two, such as Figure 4 and Figure 5 As shown, the incinerator body 1 is provided with an incineration chamber 16 and a heat insulation chamber 17 sequentially from the inside and outside, the grate frame 3 is arranged on the inner wall of the incineration chamber 16, and the driving device is arranged in the heat insulation chamber 17 to prevent the incineration chamber 16 The high temperature inside affects the driving device. The inwall of the heat insulating chamber 17 can be equipped with insulating material to further reduce the temperature in it, reduce the material requirements of the driving device, and reduce the cost. The insulating material can be glass fiber, vacuum board, etc.

[0030] Further, as Figure 5 As shown, the driving device includes an intermediate shaft 22, and an intermediate shaft 22 is rotated between the adjacent first rotating shaft 7 and the second rotating shaft 9, and an intermediate gear 23 is arranged on the intermediate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com