The pressure control method in the refining furnace with single blower and multiple ducts

A control method and technology of internal pressure, applied in furnace control devices, furnaces, reverberatory furnaces, etc., can solve the problems of increasing energy consumption, increasing production costs, and the quality of anode plates cannot be guaranteed, and meeting the requirements of reducing prior knowledge , the effect of saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

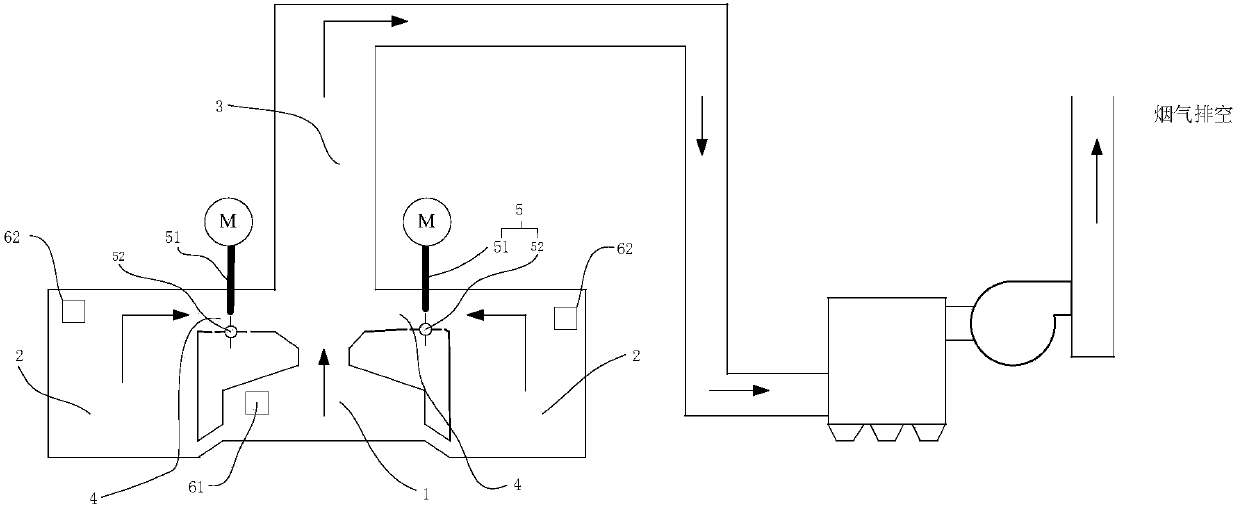

[0022] see figure 1As shown, the single-fan multi-channel refining furnace of the present invention includes a combustion furnace 1 and several reverberatory furnaces 2 arranged on the side of the combustion furnace 1. The combustion furnace 1 is connected with a main passage 3, and the main passage 3 is connected to the Each reverberatory furnace 2 is provided with an auxiliary channel 4 between the upper part, and the main channel 3 is communicated with a draft assembly, and the valve assembly 5 matched in the auxiliary channel 4 is arranged in the described auxiliary channel 4, and the valve assembly 5 is arranged in the auxiliary channel 4. The assembly 5 includes a gate 51 rotatably connected to one side of the auxiliary passage 4 and a balance wheel 52 arranged on the other side of the auxiliary passage 4. The combustion furnace 1 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com