Variable-takt operation method for simulating two-dimensional product compact layout by using convex hull and rubber band

An operation method and rubber band technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of no operation method, increasing the complexity of the simulation process, and inability to improve the efficiency of rubber band simulation layout design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment

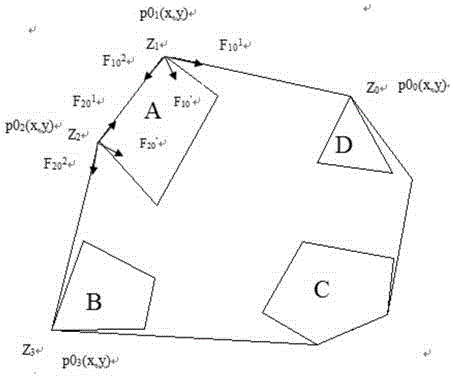

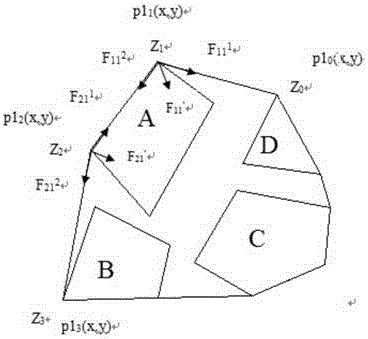

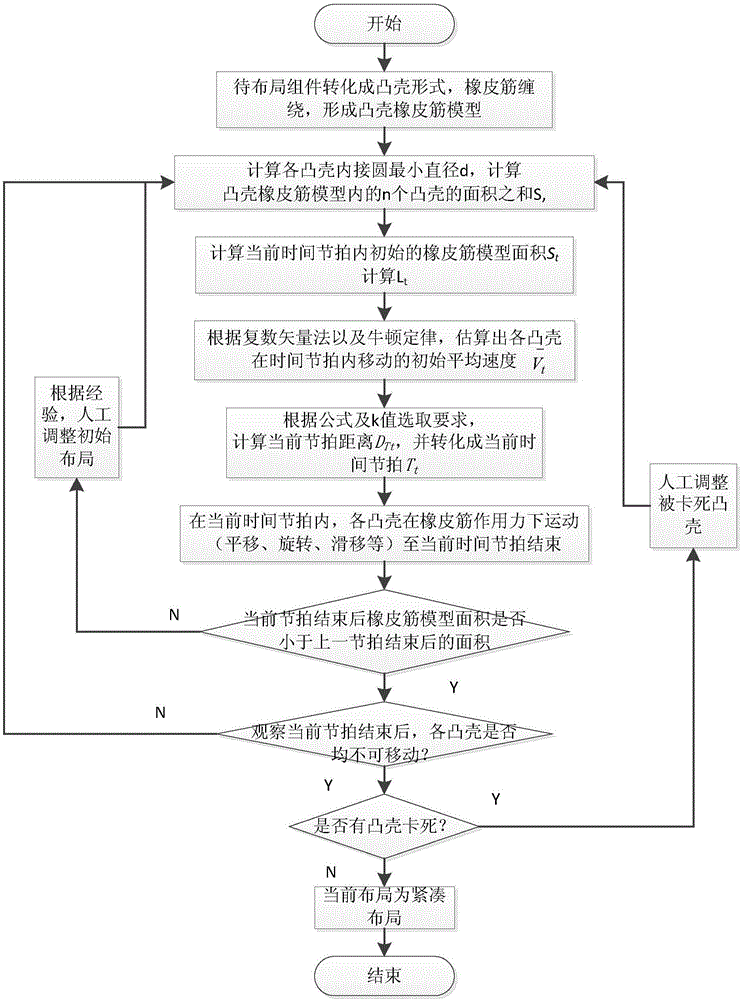

[0067] In this embodiment of the variable tempo operation method of the convex-hull rubber band simulating the compact layout of the two-dimensional product, the rubber band surrounds the periphery of the four components, and each component is simplified into a two-dimensional convex shell, which constitutes the convex-hull rubber band model of this embodiment. Such as figure 2 As shown, the rubber band is the outer boundary, and the projection of each component on the plane of the model is shown, that is, the convex hull. The convex hull in the upper left corner is A, and the counterclockwise order is B, C, and D; the rubber band of the model The elastic force of the ribs is applied to the four convex shells participating in the layout, causing the convex shells to move, rotate and slide after collision, and finally obtain the compact layo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com