Transport container for low-abundance uranium-containing waste liquid

A transport container and low-abundance technology, which is applied in the field of low-abundance uranium-containing waste liquid transport containers, can solve the problems of good shielding performance, good impact resistance, and lack, and achieves high safety, leakage prevention, and complete monitoring systems. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

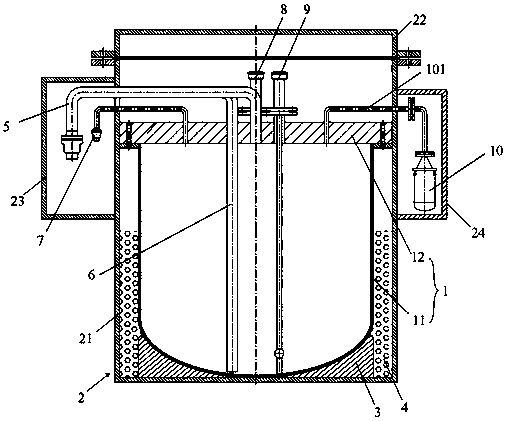

[0027] The low-abundance uranium-containing waste liquid transport container of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments of the specification:

[0028] Such as figure 1 As shown, a low-abundance uranium-containing waste liquid transport container includes an inner container 1 and an outer container 2 set outside the inner container 1, and the inner container 1 includes an inner cylinder 11 and an open end connected to the inner cylinder 11 Welded and fixed inner cover plate head 12, the bottom of the inner cylinder 11 is an ellipsoid protruding outward; the inner cover plate head 12 is equipped with a suction pipe 5, a liquid discharge pipe 6, a compressed air pipe 7, a pressure Sensor 8, liquid level sensor 9 and respirator connecting pipe 101; the outer container 2 includes an outer cylinder 21 and an outer cover plate head 22 connected with the open end of the outer cylinder 21 by bolts, and the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com