Bus integrated assembly for low-voltage power distribution cabinet

A power distribution cabinet and busbar technology, applied in the field of low-voltage power distribution cabinet components, can solve the problems of burnt out circuit breakers, difficult heat dissipation, easy burnout of circuit breakers, etc., to achieve high safety, improve product quality, and good heat dissipation performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

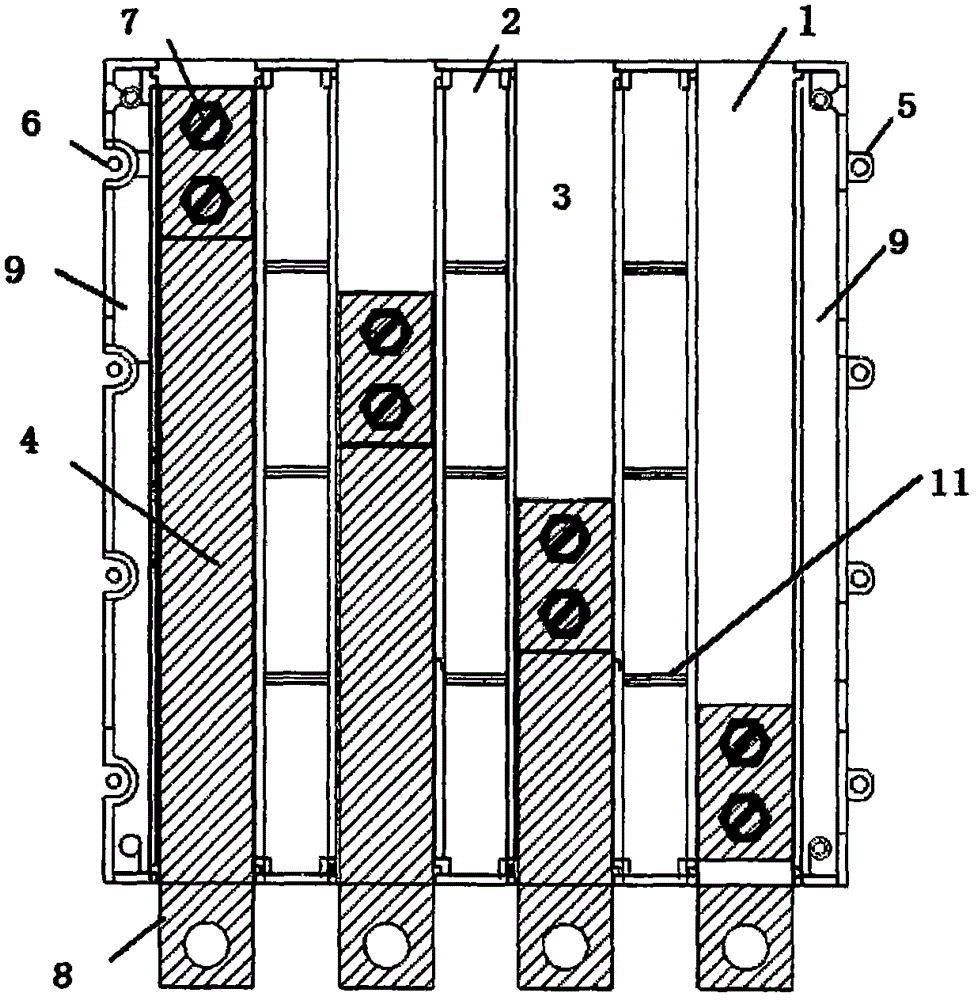

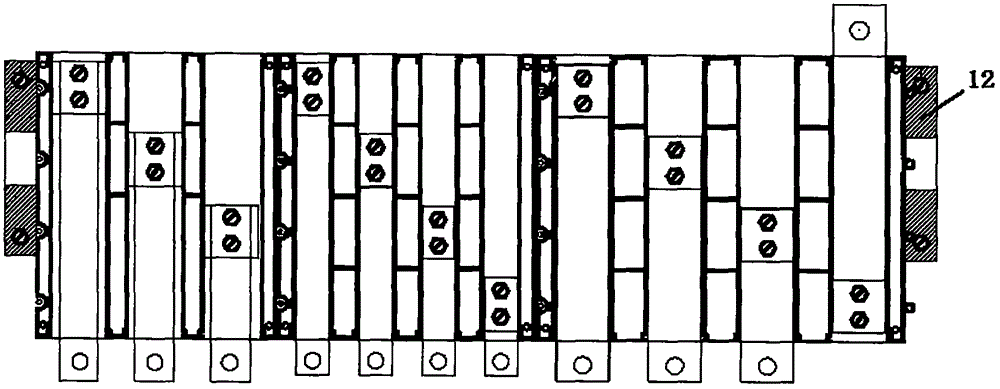

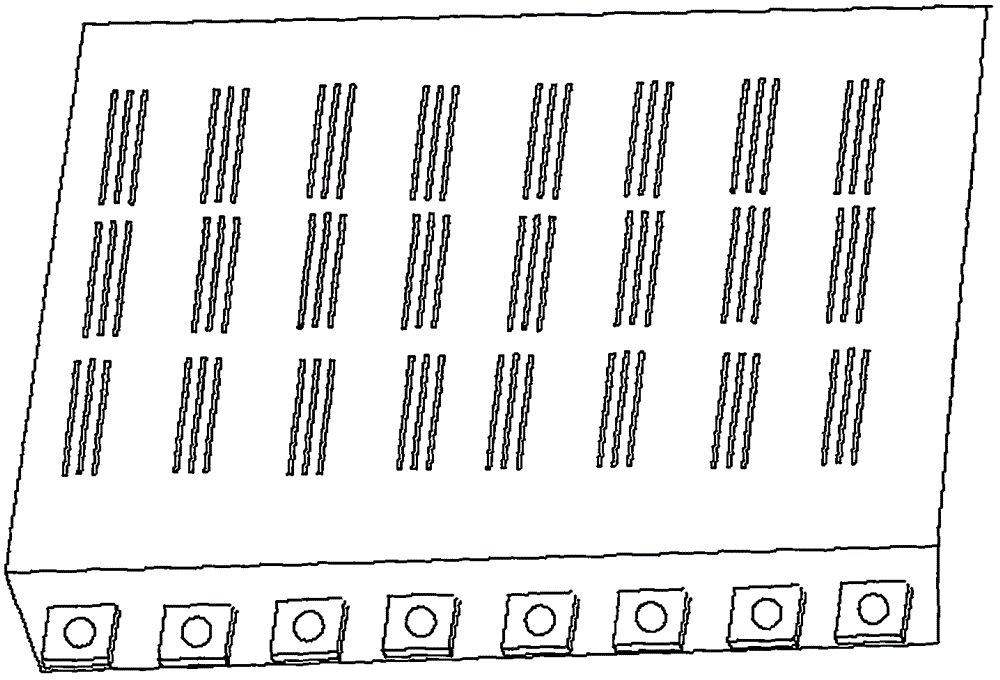

[0023] A low-voltage power distribution cabinet bus integrated assembly, including a plurality of integrated bus integrated unit components, such as figure 1 As shown, each busbar integrated unit assembly includes a substrate 1, and the left and right sides of the front of the substrate 1 have two left and right raised sides 9, and a plurality of interphase insulation parallel to the raised sides 9 are arranged between the two raised sides 9. Strip 2, raised edge and interphase insulating strip 2 can be a solid strip raised from the front of the substrate, or a frame-shaped structure raised from the front of the substrate 1. In this embodiment, the raised edge 9 and the interphase insulating The bar 2 is a raised frame structure, the inside of the frame structure is hollow, and a reinforcing rib 11 is arranged in the middle. An accommodating groove 3 is formed between the interphase insulating strip 2 and the raised edge 9 and between adjacent interphase insulating strips 2, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com