A mobile robot anti-short circuit automatic charging structure

A mobile robot and automatic charging technology, applied in current collectors, electric vehicles, electrical components, etc., can solve problems such as low efficiency, high cost, low success rate, etc., and achieve the effect of preventing touch short circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

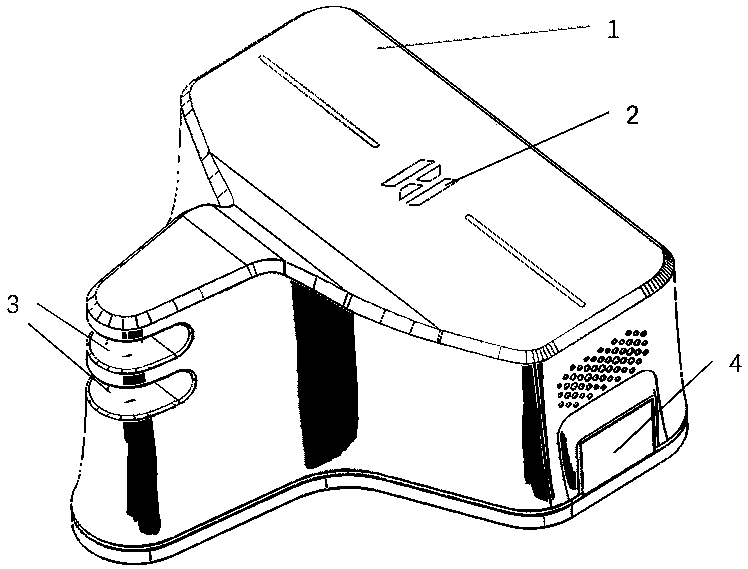

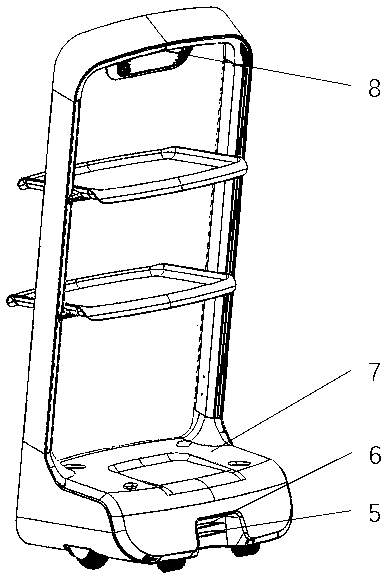

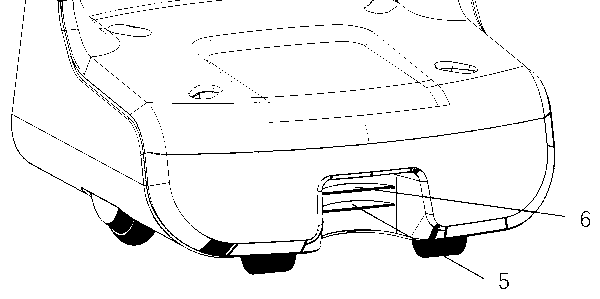

[0016] A mobile robot anti-short circuit automatic charging structure includes a robot body, a charging base body, a robot charging plate, and a charging contact. When the robot recognizes that it needs to be charged through battery power detection, the robot first moves autonomously to the vicinity of the charging stand; the camera installed on the head of the robot accurately positions and adjusts its posture to dock with the charging stand by identifying the marks on the charging stand; the charging plate on the robot body The charging contact on the charging stand is thus in contact. When the contact between the electrode plate and the contact is completed and the identification current is passed, the robot automatically turns on the charging mode until the charging process is completed.

[0017] like figure 1 As shown, the automatic charging stand body 1 is composed of the identification mark 2 for automatic charging and docking of the robot on the top of the charging sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com